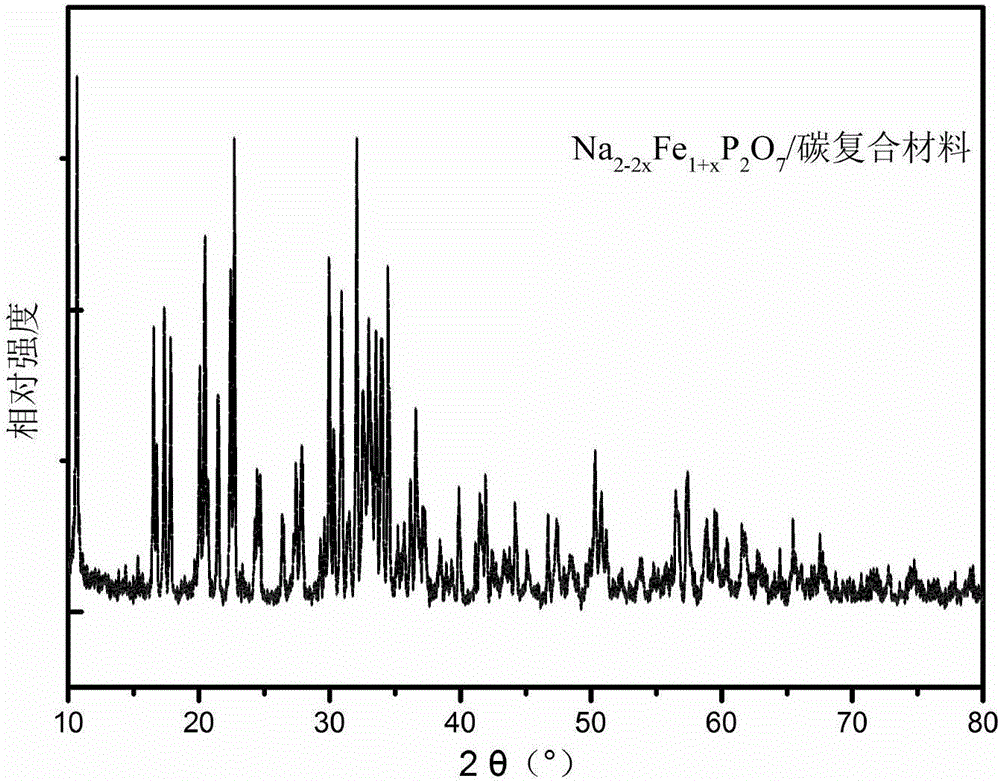

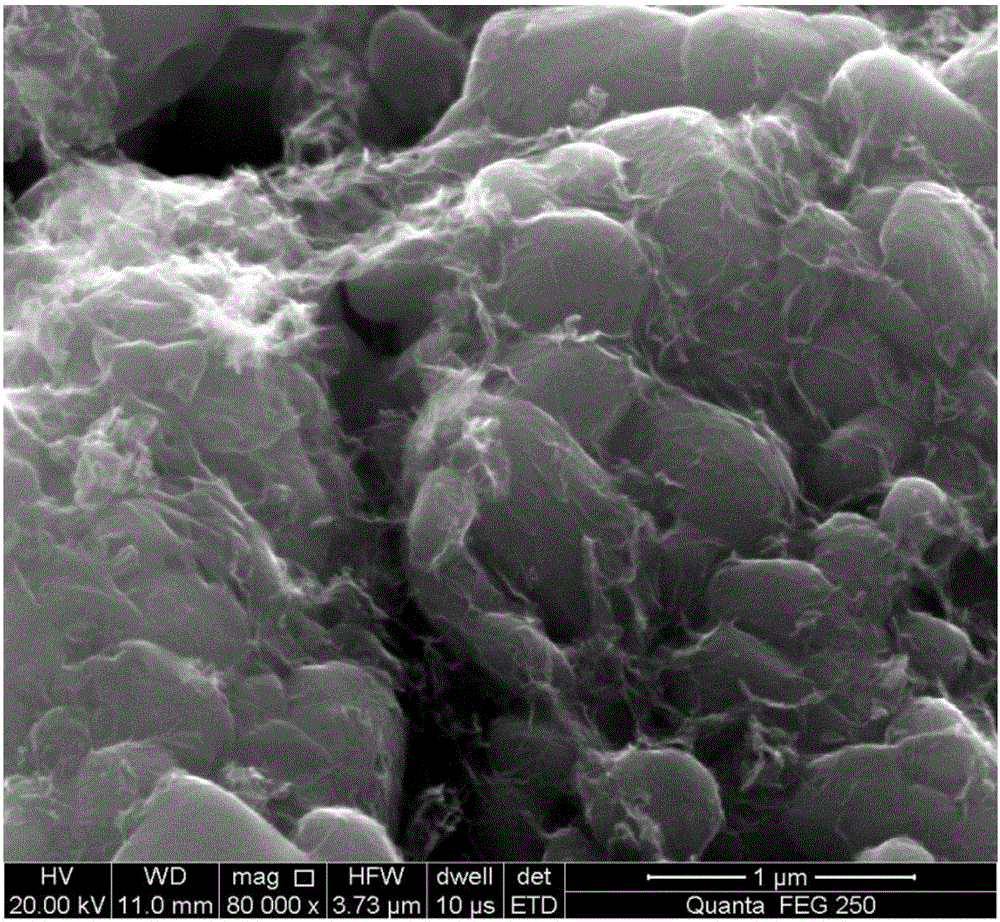

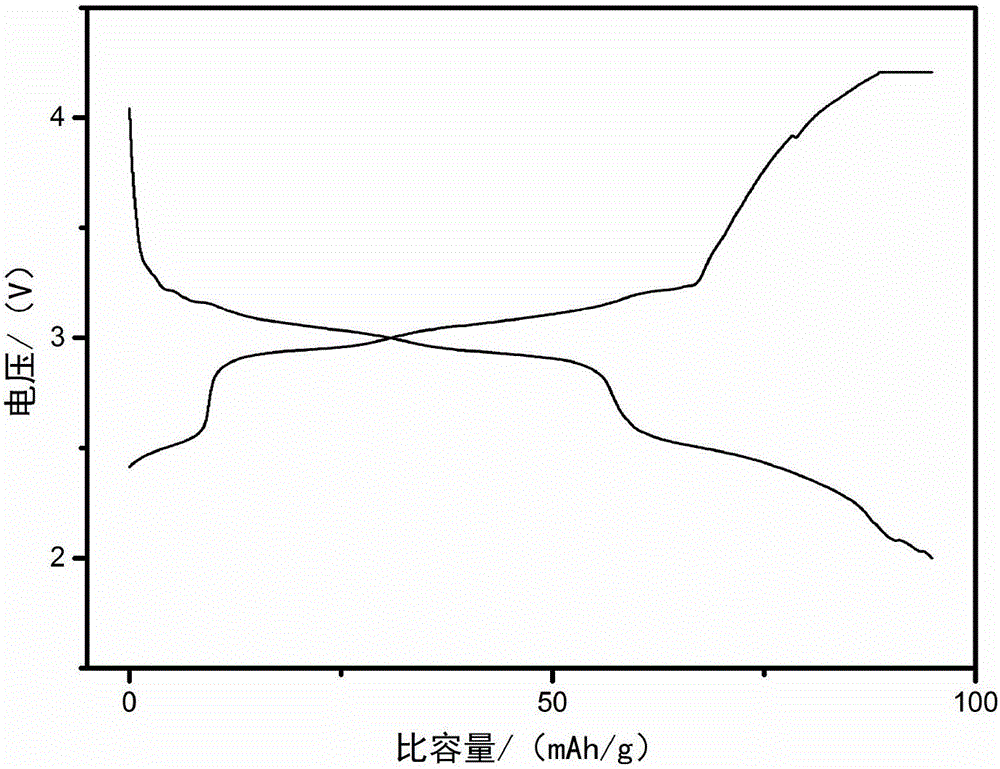

Na<2-2x>Fe<1+x>P<2>O<7>/carbon composite material and preparation method and application thereof

A carbon composite material and composite material technology, used in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of low voltage platform, short cycle life, etc., to reduce impurity, less impurity, calcination temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment includes the following steps:

[0051] (1) This embodiment is designed to generate 0.03mol of the target product Na 2-2x Fe 1+x P 2 O 7 , Prepare solution 100mL: Weigh 0.827g glucose dissolved in 40mL ethylene glycol solution (the ratio of ethylene glycol and deionized water is 1:1), respectively weigh 0.06mol ammonium dihydrogen phosphate, 0.03mol nitric acid Iron and 0.0315 mol of sodium carbonate were separately dissolved in 20 mL of deionized water and stirred to dissolve. Add the phosphorus source, iron source, and sodium source to the alcohol solution of glucose drop by drop in the order of the phosphorus source, iron source, and sodium source, at a rate of 15mL / min, with vigorous stirring, and leave to stand for 24h after addition;

[0052] (2) Pour the mixed emulsion treated in step (1) into a stainless steel reactor. The volume of the reactor is 150 mL and the filling volume is 66.67%. The stainless steel reactor is placed in a 150°C constant tempera...

Embodiment 2

[0060] This embodiment includes the following steps:

[0061] (1) This embodiment is designed to generate 0.03mol of the target product Na 2-2x Fe 1+x P 2 O 7 / Carbon composite material, prepare 100mL solution: Weigh 1.634g of citric acid and dissolve in 40mL ethylene glycol solution (the ratio of ethylene glycol to deionized water is 1:1), respectively weigh 0.06mol of ammonium dihydrogen phosphate , 0.03mol of ferric nitrate, 0.0315mol of sodium carbonate, respectively, dissolved in 20mL of deionized water, and stirred to dissolve. Add the phosphorus source, iron source and sodium source to the alcoholic solution of citric acid drop by drop in the order of the phosphorus source, iron source, and sodium source. The addition rate is 15 mL / min, with vigorous stirring. After the addition is complete, let it stand for 24 hours;

[0062] (2) Pour the mixed emulsion treated in step (1) into a stainless steel reactor. The volume of the reactor is 150 mL and the filling volume is 66.67%. ...

Embodiment 3

[0066] This embodiment includes the following steps:

[0067] (1) This embodiment is designed to generate 0.03mol of the target product Na 2-2x Fe 1+x P 2 O 7 / Carbon composite material, to prepare 100mL solution: Weigh 1.634g glucose and dissolve it in 40mL ethylene glycol solution (the ratio of ethylene glycol to deionized water is 1:1), respectively weigh 0.06mol ammonium dihydrogen phosphate, 0.03 mol of ferric nitrate and 0.0315 mol of sodium carbonate were dissolved in 20 mL of deionized water, and stirred to dissolve. Add the phosphorus source, iron source, and sodium source to the alcohol solution of glucose drop by drop in the order of the phosphorus source, iron source, and sodium source, at a rate of 15mL / min, with vigorous stirring, and leave to stand for 24h after addition;

[0068] (2) Pour the mixed emulsion treated in step (1) into a stainless steel reactor. The volume of the reactor is 150 mL and the filling volume is 66.67%. The stainless steel reactor is placed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com