Circulating water underground cooling device

A cooling device and circulating water technology, which is applied in water shower coolers, steam/steam condensers, direct contact heat exchangers, etc., can solve the problems of increasing air discharge and evaporation water loss, and achieve improved thermal efficiency and zero Emission and temperature reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

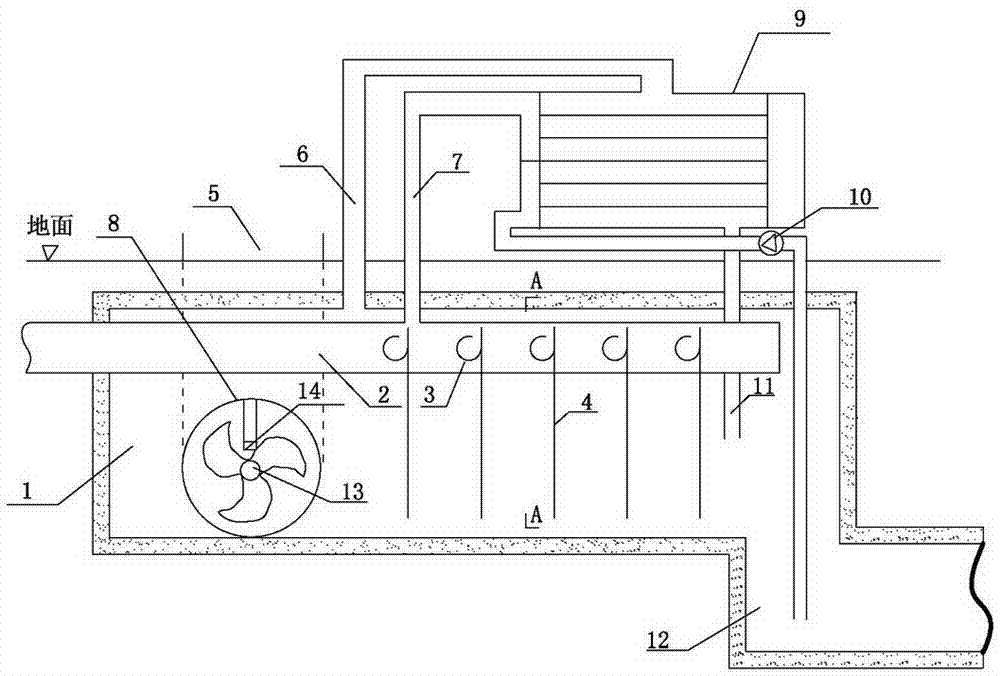

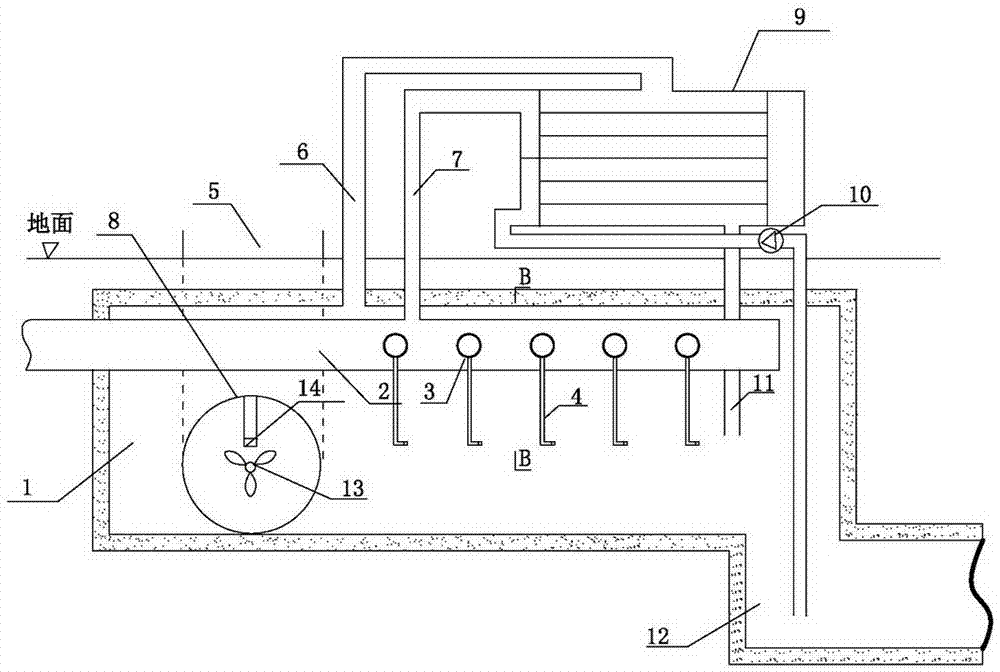

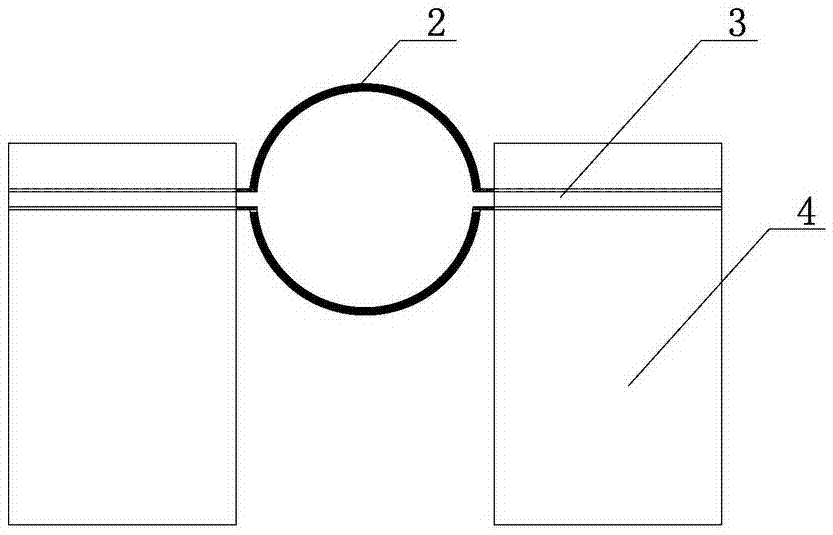

[0025] Concrete pouring a water-drying tunnel 1 at the underground constant temperature layer, there are horizontal underground cooling ducts 8 on both sides of the water-drying tunnel 1, and the ventilation ducts 8 are communicated with the ground air inlet 5. Spraying device 14 is arranged in ventilation pipe 8, and spraying device 14 is to have atomizing nozzle at the end of many drainage pipes, and spraying device 14 water is to lead from the cool water in the reservoir 12. The spraying device 14 cools down the air, and the low-temperature air is discharged into the water-drying hole 1 by the induced draft fan 13 . The main water pipe 2 is connected to the outlet of the condenser and introduced into the water-drying hole 1, the hot water in the main water pipe 2 is distributed to the branch pipe 3 to flow out, and is dissipated by the heat sink 4, and the heat sink can be connected to the flat plate type The upper part of the heat sink has an opening above the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com