Electric soldering iron temperature controller

A technology for temperature controllers and electric soldering irons, applied in the direction of soldering irons, electric heating devices, electrical components, etc., can solve problems such as easy oxidation of soldering iron tips, energy waste, short time, etc., and achieve the effect of solving energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

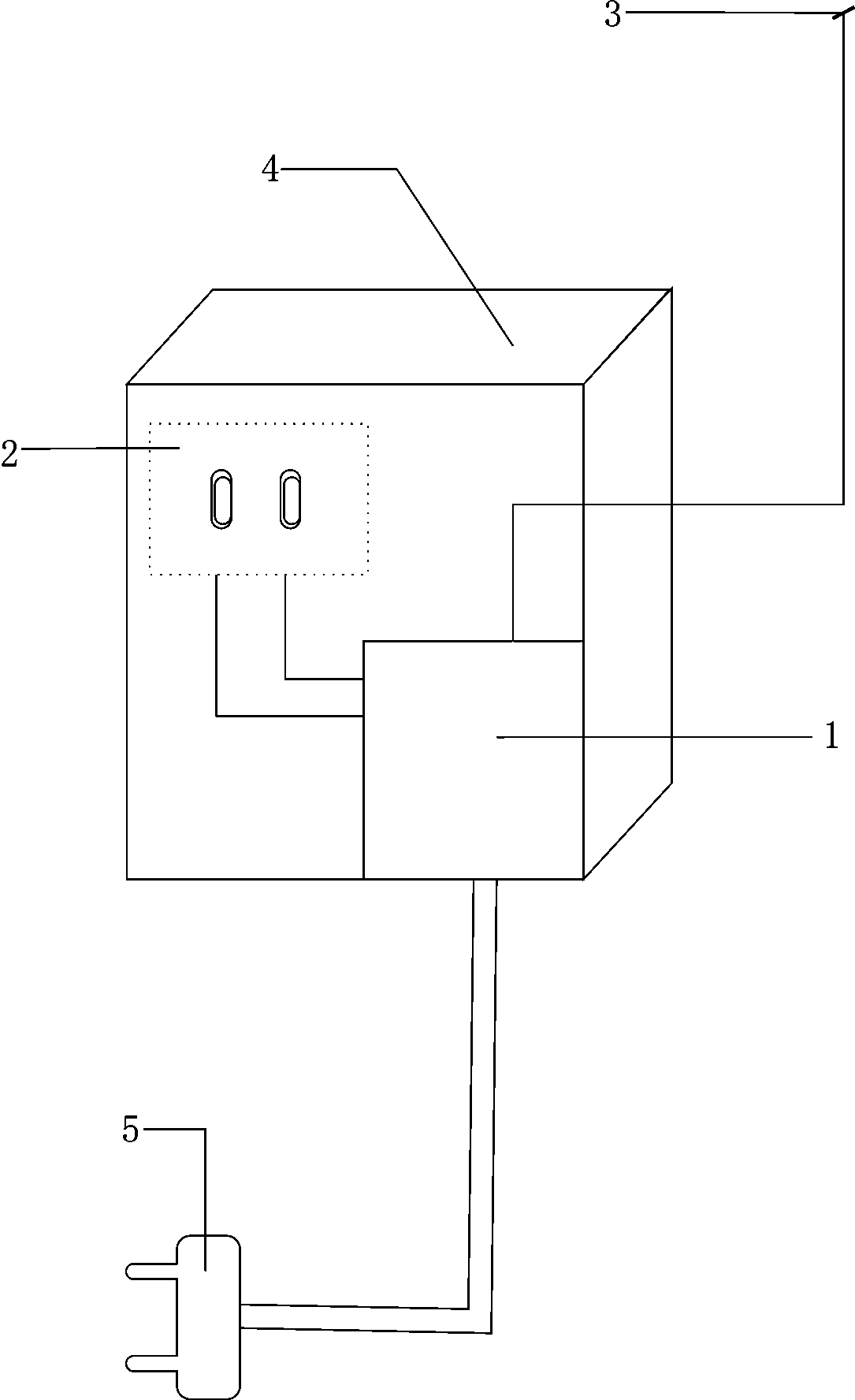

[0014] figure 1 It is a structural diagram of a temperature controller for an electric soldering iron in the present invention. The present invention is composed of a control module 1, a socket 2, a sensor 3, a main body 4, and a plug 5. exist figure 1 Among them, the signal input end of the control module 1 is connected to the sensor 3 , the output end of the control module 1 is connected to the socket 2 , and a power cord with a plug 5 is drawn from the input end of the control module 1 .

[0015] The control module 1 is installed inside the main body 4 .

[0016] The socket 2 is installed at the front upper left corner of the main body 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com