Hydraulic automatic reversing device

A technology of automatic reversing and water pressure, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of frequent replacement of motors, poor reliability, and easy contamination of work objects, etc., to avoid excessive space occupation , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

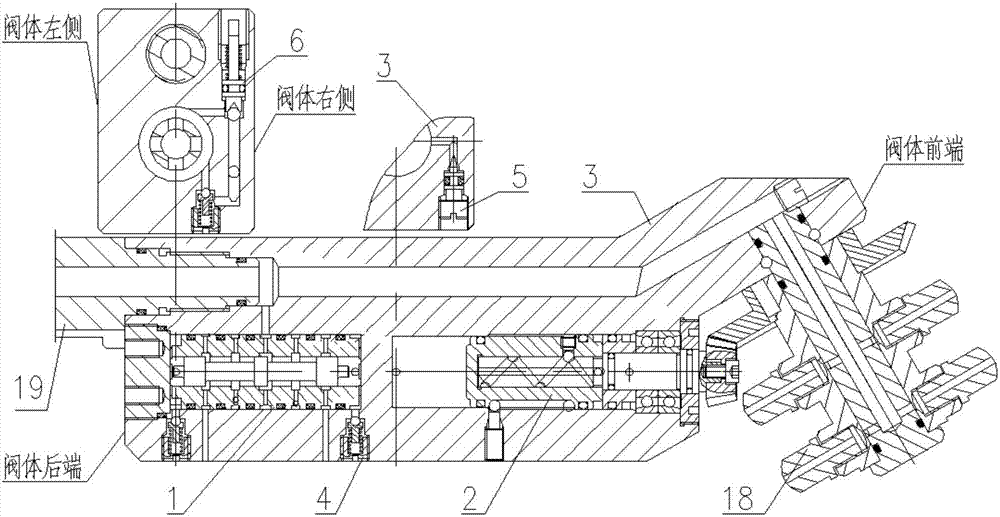

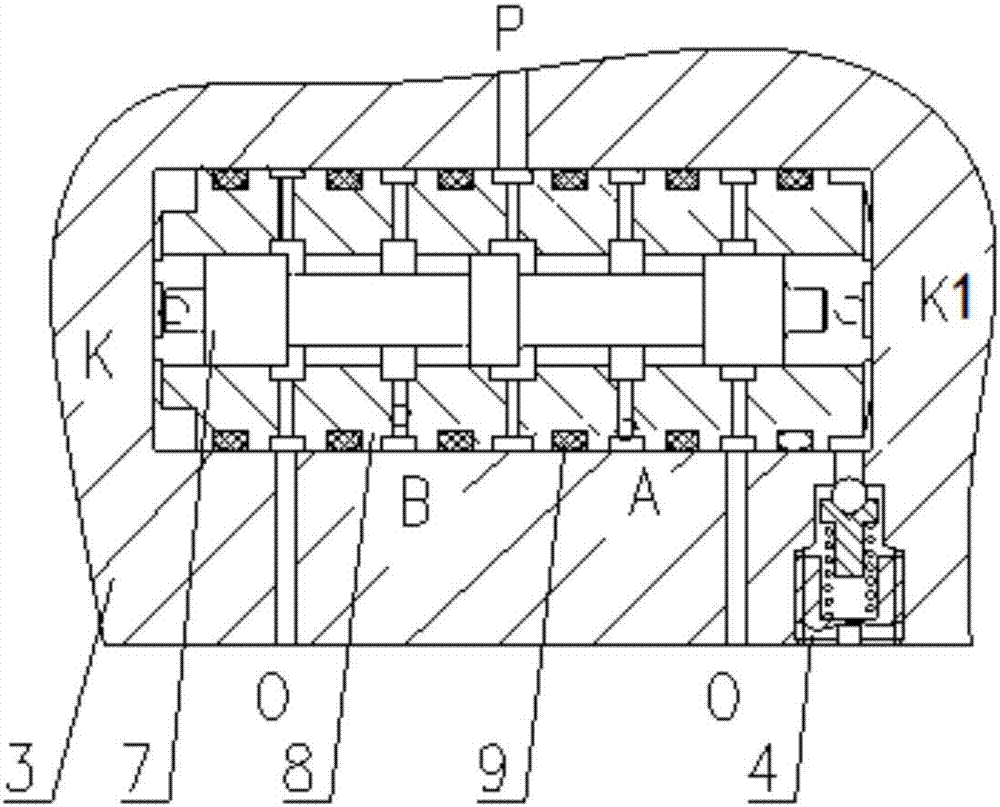

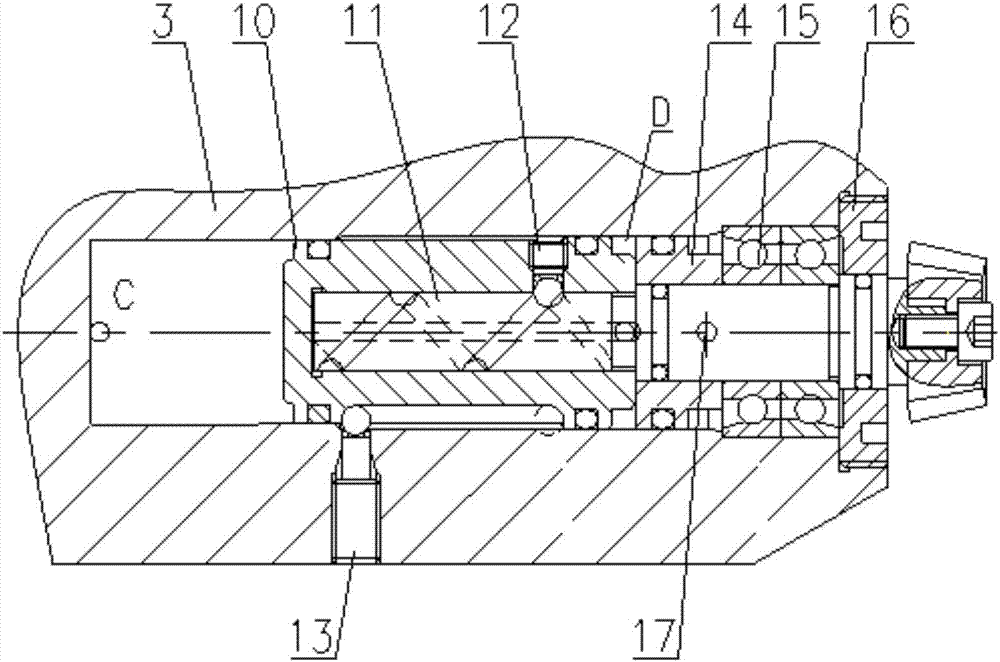

[0023] Such as figure 1 As shown, a hydraulic automatic reversing device includes an automatic reversing valve 1, a reciprocating hydraulic cylinder 2, a valve body 3, a one-way valve II4, a throttle valve 5, a one-way valve I6, a nozzle assembly 18 and a transfer Body 19. The automatic reversing valve 1 and the reciprocating hydraulic cylinder 2 are installed inside the valve body 3, and the reciprocating hydraulic cylinder 2 is located on the right side of the automatic reversing valve 1. The one-way valve II4 , the throttle valve 5 and the one-way valve I6 are all located inside the valve body 3 . The adapter body 19 is installed at the rear end of the valve body 3 , and the nozzle assembly 18 is installed at the front end of the valve body 3 . The automatic reversing valve 1 drives the reciprocating hydraulic cylinder 2 . The reciprocating hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com