A low starting critical stress rare earth magnetically controlled shape memory alloy and its preparation method

A memory alloy and critical stress technology, applied in the field of shape memory materials, can solve the problems of difficult to meet engineering applications, limited wide-scale promotion, low phase transition temperature, etc. Mechanical properties, the effect of improving magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

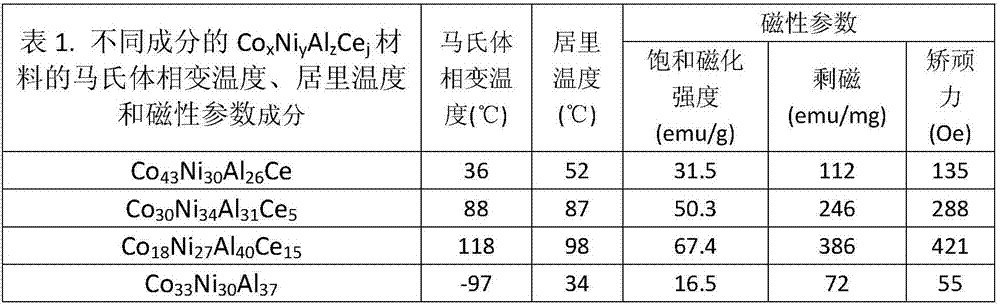

[0027] The composition of the preparation is Co 43 Ni 30 Al 26 Ce's shape memory alloy with magnetic field controllable deformation, its preparation method is as follows:

[0028] (1) Weighing Co, Ni, Al, Ce with a purity of 99.9% respectively;

[0029] (2) Put the weighed raw materials in the crucible, and use vacuum melting. The melting conditions are: a.1×10 -2MPa vacuum state; b. The melting temperature is 1350°C; c. The melting process uses magnetic stirring; d. The melting time is 0.5 hours.

[0030] (3) Carry out vacuum magnetic field heat treatment to the above-mentioned smelted alloy ingot, the treatment conditions are: temperature 550°C; time: 24 hours; vacuum degree: 1×10 -3 Mpa; Applied magnetic field strength: 1×10 6 A·m -1 .

[0031] (4) Then cool with the furnace, the cooling rate range is: 0.01°C / s; the magnetic field reduction rate is: 1500A m -1 ·s -1 ; Cool to room temperature and take out to obtain the final shape memory alloy.

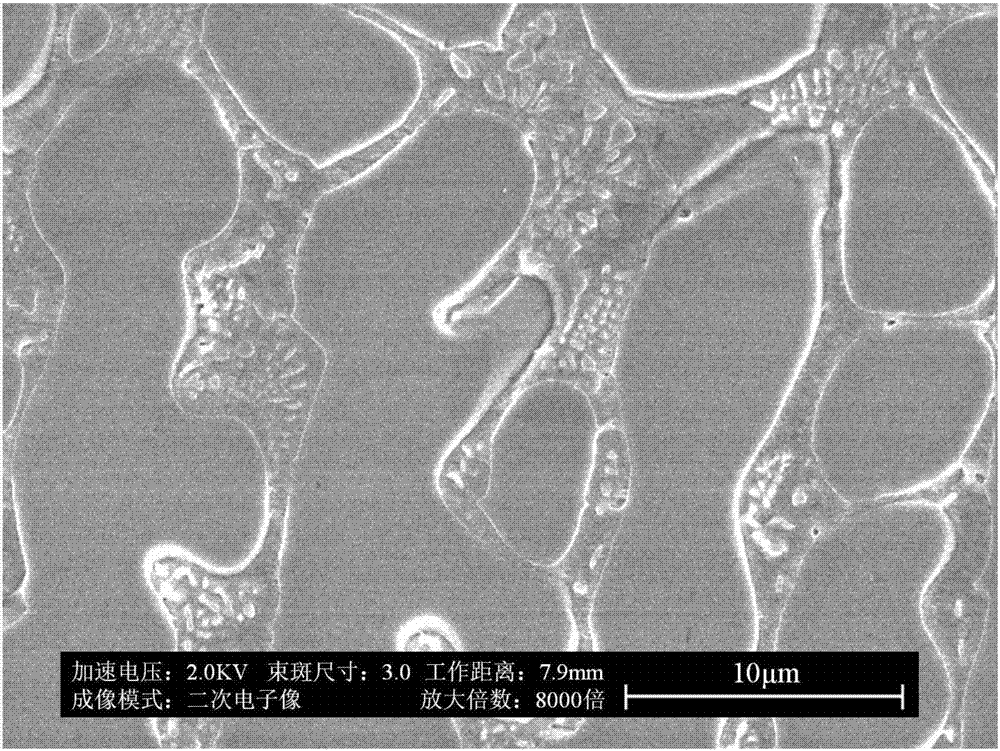

[0032] The polycr...

Embodiment 2

[0034] The composition of the preparation is Co 30 Ni 34 al 31 Ce 5 The shape memory alloy with magnetic field controllable deformation, its preparation method is as follows:

[0035] (1) Weighing Co, Ni, Al, Ce with a purity of 99.9% respectively;

[0036] (2) Put the weighed raw materials in the crucible, and use vacuum melting, the melting conditions are: a.7×10 -3 MPa vacuum state; b. The melting temperature is 1400°C; c. The melting process uses magnetic stirring; d. The melting time is 0.4 hours.

[0037] (3) Carry out vacuum magnetic field heat treatment to the above-mentioned smelted alloy ingot, the treatment conditions are: temperature 500°C; time: 32 hours; vacuum degree: 6×10 -3 Mpa; Applied magnetic field strength: 1×10 7 A·m -1 .

[0038] (4) Then cool with the furnace, the cooling rate range is: 0.3°C / s; the magnetic field reduction rate is: 5000A m -1 ·s -1 ; Cool to room temperature and take out to obtain the final shape memory alloy.

[0039] The p...

Embodiment 3

[0041] The composition of the preparation is Co 18 Ni 27 al 40 Ce 15 The shape memory alloy with magnetic field controllable deformation, its preparation method is as follows:

[0042] (1) Weighing Co, Ni, Al, Ce with a purity of 99.9% respectively;

[0043] (2) Put the weighed raw materials in the crucible, and use vacuum melting. The melting conditions are: a.1×10 -3 MPa vacuum state; b. The melting temperature is 1450°C; c. The melting process uses magnetic stirring; d. The melting time is 0.3 hours.

[0044] (3) Carry out vacuum magnetic field heat treatment to the above-mentioned smelted alloy ingot, the treatment conditions are: temperature 450 ℃; time: 48 hours; vacuum degree: 1×10 -3 Mpa; Applied magnetic field strength: 3×10 7 A·m -1 .

[0045] (4) Then cool with the furnace, the cooling rate range is: 1°C / s; the magnetic field reduction rate is: 8000A m -1 ·s -1 ; Cool to room temperature and take out to obtain the final shape memory alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com