Low-compression-ratio ultrathick EH36 ship plate steel and preparation method thereof

An EH36, bit-reduced technology, applied in the field of iron and steel metallurgy, can solve the problems of adverse effects on the stability of extra-thick plates, high strength and high impact toughness, and wide final cooling temperature range, so as to shorten the product delivery cycle, improve impact toughness, The effect of a large final cooling temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

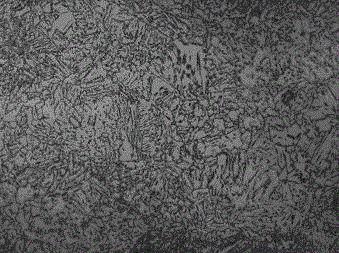

[0027] A total of four slabs from two furnace numbers used for conventional production of EH36 were selected, and the composition met the requirements of the classification society and GB712EH36 steel grade. The thickness of the continuous casting slab is 370 mm, and the chemical composition is shown in Table 1. Rolled into finished steel plates with a thickness of 100-150mm, the temperature control of the rolling process is in accordance with the conventional production of normalized 60-100mm EH36 steel plate process, the rough rolling temperature is between 1050-1150 ℃, the finishing rolling start temperature is ≤880 ℃, and the pass is in accordance with Rolling load is controlled, and the rolling pass reduction rate distribution figure of embodiment 1 is as follows image 3 shown. Cool after rolling, and the cooling temperature is 600-660°C. Remarks: In this embodiment, laminar cooling or accelerated cooling may not be performed after rolling the steel plate. Rapid water ...

Embodiment 1

[0030]Embodiment 1 and embodiment 2 are extra-thick EH36 plates of 120 mm, and embodiments 3 and 4 are extra-thick EH36 plates of 150 mm. For the use of extra-thick plates, the performance uniformity in the thickness direction of the steel plate is the most concerned by users for extra-thick plates. 1 / 2 properties are tested for tensile, impact and metallographic examination. From the perspective of steel plate tensile properties, the transverse tensile properties of steel plate yield strength are between 355-400MPa, the tensile strength is between 550-560MPa, and the elongation is moderate. The tensile properties of the 1 / 2 thickness of the steel plate are slightly lower than that of the 1 / 4 thickness, but the difference is not significant. The low-temperature impact toughness of the steel plate is shown in Table 2, and the -40°C longitudinal impact toughness value at 1 / 4 thickness of the steel plate is ≥100J. The -40°C longitudinal impact toughness value at 1 / 2 thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com