Construction method and application of genetically engineering strain capable of producing indigo pigment

A technology of genetically engineered strains and indigo pigments, applied in the field of food additive manufacturing, can solve problems such as difficult separation and purification, achieve efficient production and improve the effect of indigo pigment synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

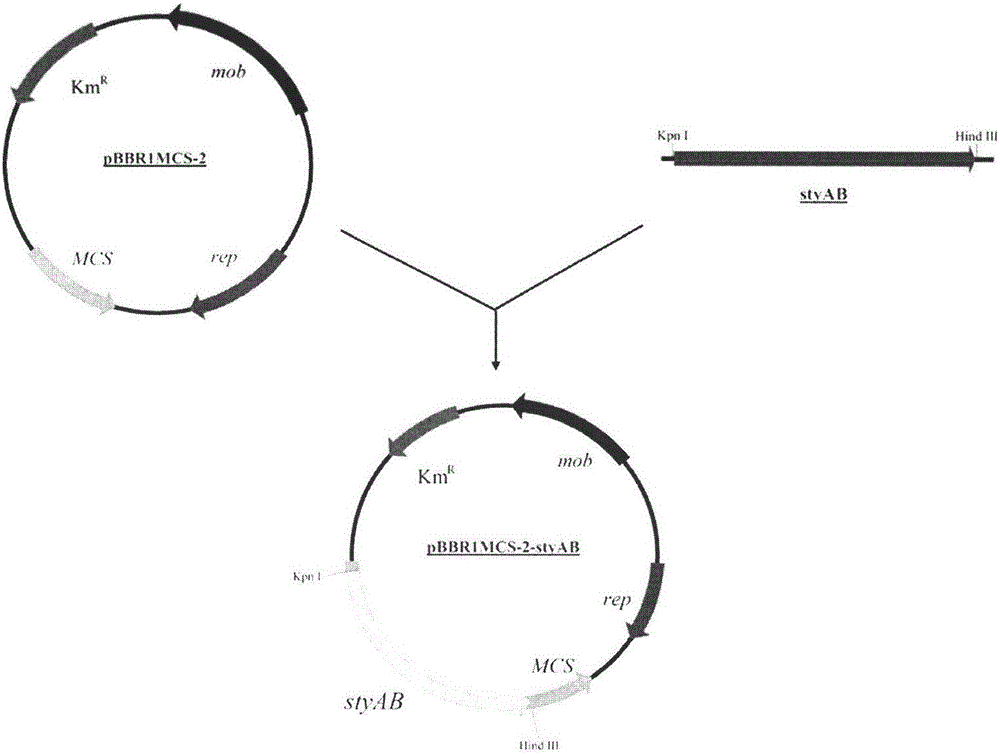

[0024] 1. Cloning of styAB gene

[0025] 1.1 Extraction of PseudomonasputidaB4 Genomic DNA

[0026] The freshly activated Pseudomonasputida B4 strain was inoculated into LB liquid medium, placed in a shaker at 30°C, and shaken at 220rpm for overnight cultivation.

[0027] (1) Take 1 mL of bacterial liquid into a 1.5 mL centrifuge tube, centrifuge at 12,000 rpm for 1 min at room temperature, and discard the supernatant;

[0028] (2) Bacterial genomic DNA extraction kit (Tiangen Biochemical Technology (Beijing) Co., Ltd.) was used to extract genomic DNA.

[0029] 1.2 Cloning of styAB gene

[0030] Specific primers were designed, and the styAB gene fragment was amplified by PCR method using PseudomonasputidaB4 genomic DNA as a template.

[0031] styAB gene primer sequence:

[0032] Upstream primer: 5'-CGGGGTACCAGCAACCCACAACAAAAACAAG-3'

[0033] Downstream primer: 5'-CCCAAGCTTGTGATCGGCACAGAAAGG-3'

[0034] PCR reaction system

[0035]

[0036] KpnI and HindIII restrictio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com