Styrene cyclooxygenase gene and application thereof

A cyclooxygenase and gene technology, applied in the fields of oxidoreductase, genetic engineering, plant gene improvement, etc., can solve problems such as harsh reaction conditions, low selectivity, and difficult separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

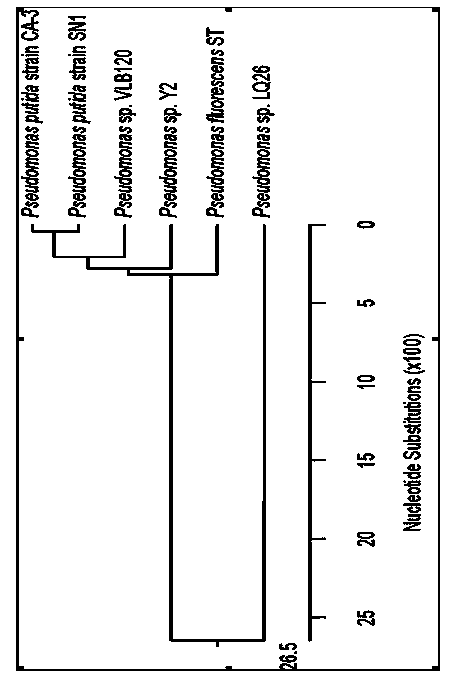

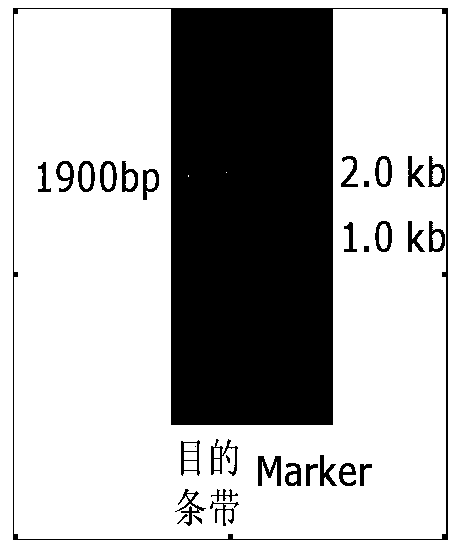

[0086] Embodiment 1 screening styrene cyclooxygenase gene

[0087] Environmental samples were enriched in culture medium containing M12 inorganic salt (Hartmans et al. (1989) APPl.Environ.Microbiol., 55(11), 2850-2855) and styrene 2mM for 8 days, spread after dilution Cultured on a screening plate (M12+styrene 2mM+4-chloroindole 0.1mM+0.01% yeast powder+1.5% agar powder) at 30°C for 2 days, blue colonies appeared, picked out, and further purified to obtain a single colony.

[0088] The screened strain was cultured with styrene (10mM) as the only carbon source, and the growth state was good.

[0089] The screened strains were grown for 8-10 hours in a medium containing M12, 3 mM styrene, 0.05% yeast powder, 0.05% tryptone, and 0.1% glucose, centrifuged, and the cells were harvested. The wet bacteria were resuspended in pH 7.0 phosphate buffer, added with 0.5mM 4-chloroindole, transformed at 37°C, 240rpm for 20min, and a dark blue substance was generated.

[0090] Therefore, t...

Embodiment 2

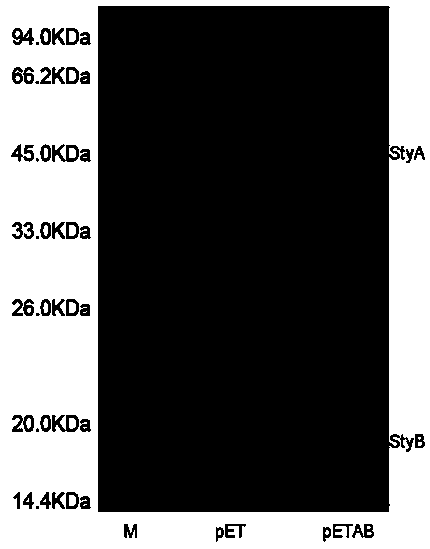

[0124] The optimization of embodiment 2 styrene cyclooxygenase expression conditions

[0125] For the construction and expression method of the recombinant E.coli (pETAB), please refer to the instructions. In order to express the recombinant protein with high activity, a single factor preliminary optimization was carried out on the expression temperature and the concentration of the inducer.

[0126] Expression temperature optimization: When the inducer IPTG is 1mM, induce the expression of styAB gene at 37°C, 30°C, 25°C, 20°C, 15°C, and 10°C respectively, take samples at different induction times, refrigerate and centrifuge, harvest the cells, and use 4- Chlorindole was used as the model substrate to detect the activity of StyAB. The result was that the total enzyme activity was the highest at 20°C and 15°C for 18-21 hours of induction, and there was no significant difference in the total activity between the two, so 20°C was chosen as the expression temperature.

[0127] In...

Embodiment 3

[0129] Embodiment 3 Styrene cyclooxygenase whole cell biotransformation condition optimization

[0130] For protein expression, Example 2 was used to optimize the conditions, and the collected wet bacteria were used for whole-cell biotransformation. Preliminary single-factor optimization was carried out on the conversion reaction temperature and pH value.

[0131] Optimum reaction temperature analysis: take an equal amount of freshly cultured wet bacteria, resuspend in phosphate buffer (0.1M, pH6.5), add 10% BEHP and an equal amount of 4-Bromostyrene. Respectively at 25°C, 28°C, 30°C, 32°C, 35°C, 40°C, 45°C, 240rpm shaking reaction for 24h, take the organic phase to detect the epoxy yield by HPLC, and the epoxy yield is the highest at 30°C.

[0132] Optimum reaction pH analysis: Take an equal amount of freshly cultured wet bacteria, resuspend them in 0.1M phosphate buffer with pHs of 6.0, 6.5, 7.0, 7.5, and 8.0, add 10% BEHP and an equal amount of 4-Bromostyrene, The reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com