Method for preparing hydrocalumite based heat stabilizer from calcium-aluminum hydroxide and application of hydrocalumite based heat stabilizer

A technology of hydrocalumite and heat stabilizer, which is applied in the field of polyvinyl chloride preparation, can solve the problems of high price and achieve the effects of cheap price, reduced energy consumption and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In a 250mL single-necked flask, add 3.6223g of calcium hydroxide, 1.9212g of aluminum hydroxide, and 50.02mL of deionized water. At room temperature, the rotor was stirred at a speed of 800r / min for 30min. Add 1.3088g of anhydrous sodium carbonate to the one-necked flask, and continue to stir at room temperature for 30min. Then move the single-necked flask to an oil bath at 60°C, stir and reflux with the rotor, and react for 20 hours. After the reaction is completed, filter it with 0.08MPa suction, wash with deionized water three times, dry at 80°C for 6 hours, and grind to obtain the product Calcium Hydroxide Stone based heat stabilizer.

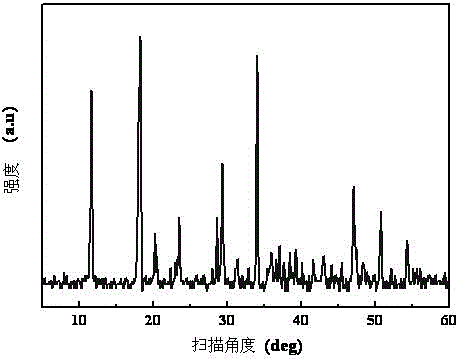

[0024] Hydrocalumite based heat stabilizer Ca 4 Al 2 (OH) 12 CO 3 5H 2 O infrared spectrum. Such as figure 1 shown.

[0025] 3540cm -1 is OH - The characteristic absorption peak of the functional group indicates that there are hydroxyl radicals generated in the product. 1430cm -1 CO 3 - The characteristic absorption pe...

Embodiment 2

[0029] In a 250mL single-necked flask, add 3.6213g of calcium hydroxide, 1.9220g of aluminum hydroxide, and 75.06mL of deionized water. At room temperature, the rotor was stirred rapidly at 1000r / min for 30min. Add 1.3052 g of anhydrous sodium carbonate to the one-necked flask, and continue stirring at room temperature for 30 min. Then move the one-necked flask to an oil bath at 60°C, stir and reflux with the rotor, and react for 20 hours. After the reaction, filter with 0.1MPa suction, wash with deionized water three times, dry at 80°C for 6 hours, and grind to obtain hydrocalumite base heat stabilizer.

Embodiment 3

[0031] In a 250mL single-necked flask, add 3.6206g of calcium hydroxide, 1.9206g of aluminum hydroxide, and 100.05mL of deionized water. At room temperature, the 900r / min rotor stirred rapidly for 30min. Add 1.3010 g of anhydrous sodium carbonate to the one-necked flask, and continue stirring at room temperature for 30 min. Then move the single-necked flask to an oil bath at 60°C, stir and reflux with the rotor, and react for 20 hours. After the reaction is completed, filter it with suction and wash it with deionized water three times, dry it at 80°C for 6 hours, and grind it to obtain hydrocalumite-based heat stabilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com