Aluminum ash series artificial quartz stone and manufacturing method thereof

A technology of artificial quartz stone and quartz stone, which is applied in the field of artificial quartz stone, can solve the problems of incomplete utilization of useful components and environmental pollution, and achieve the effects of reducing emissions and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of aluminum ash system artificial quartz stone of the present invention is characterized in that: described quartz stone mainly comprises aluminum ash powder, quartz powder, quartz sand, resin, curing agent and reaction agent; Wherein aluminum ash powder accounts for 36% of mass percentage , quartz powder accounts for 3.50% by mass, quartz sand accounts for 40% by mass, resin accounts for 20% by mass, curing agent accounts for 0.250% by mass, and reactant accounts for 0.250% by mass. The particle size of the quartz powder is 310 mesh. The particle size of the quartz sand is 25 mesh. The resin is 191 resin.

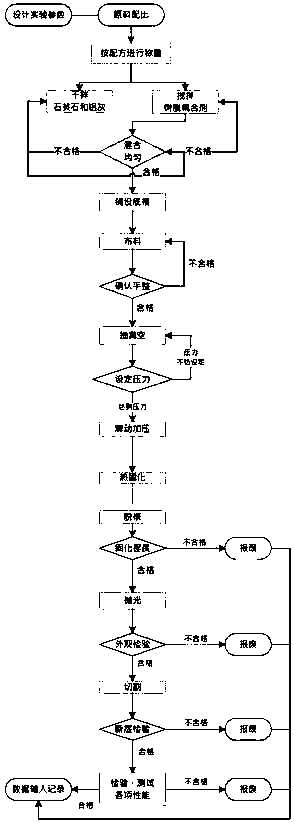

[0042] refer to figure 1 The method for making aluminum gray series artificial quartz stone for the present invention is characterized in that: the method mainly includes the following steps:

[0043] 1) Raw material ingredients

[0044] Firstly, according to the variety of designs and colors produced, the various prepared raw materials are prepared accor...

Embodiment 2

[0068] A kind of aluminum ash system artificial quartz stone of the present invention is characterized in that: described quartz stone mainly comprises aluminum ash powder, quartz powder, quartz sand, resin, curing agent and reaction agent; Wherein aluminum ash powder accounts for 35% by mass percentage , quartz powder accounts for 3.50% by mass, quartz sand accounts for 41% by mass, resin accounts for 20% by mass, curing agent accounts for 0.250% by mass, and reactant accounts for 0.250% by mass. The particle size of the quartz powder is 330 mesh. The particle size of the quartz sand is 30 mesh. The resin is 191 resin.

[0069] refer to figure 1 The method for making aluminum gray series artificial quartz stone for the present invention is characterized in that: the method mainly includes the following steps:

[0070] 1) Raw material ingredients

[0071] Firstly, according to the variety of designs and colors produced, the various prepared raw materials are prepared accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com