Normal temperature curing reactive powder concrete and preparation method thereof

A technology of active powder and concrete, applied in the field of concrete, can solve the problems of limiting the size and shape of prefabricated components, increasing production costs, etc., and achieve the effects of long service life, reduced production costs, and small self-shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

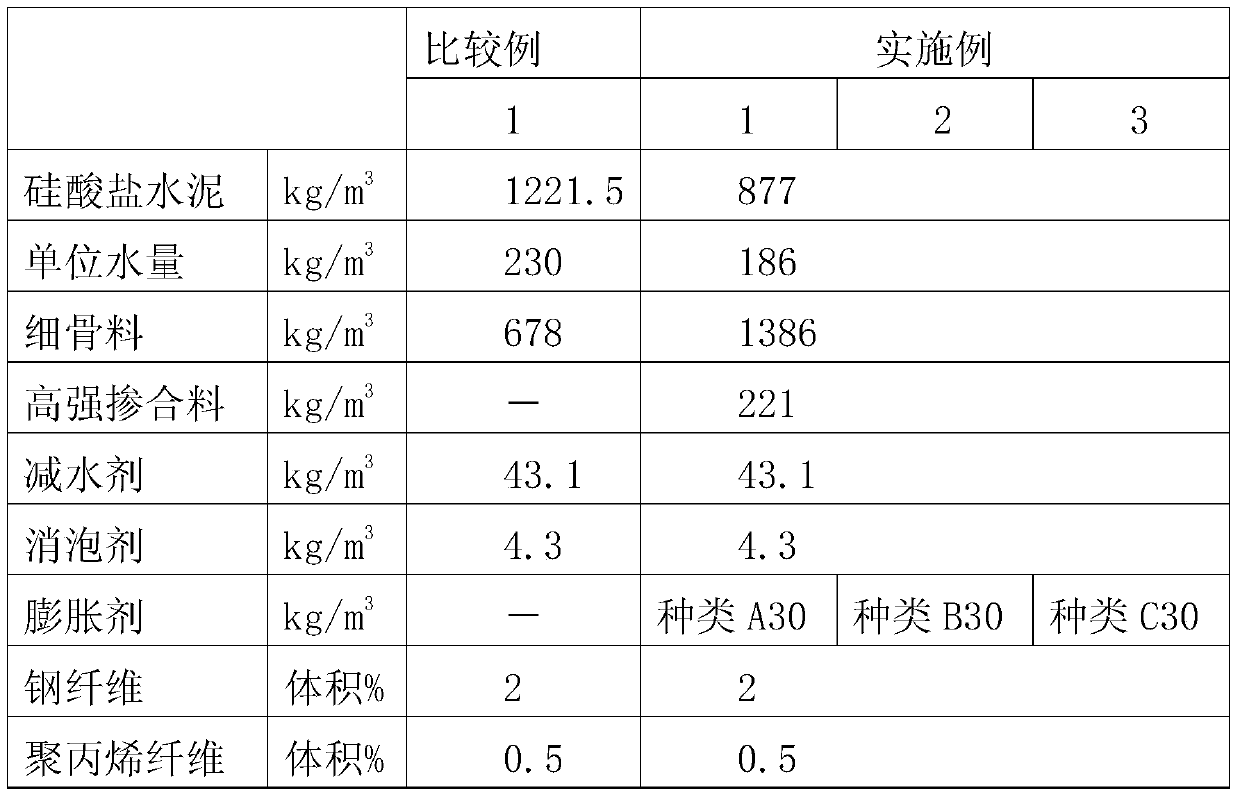

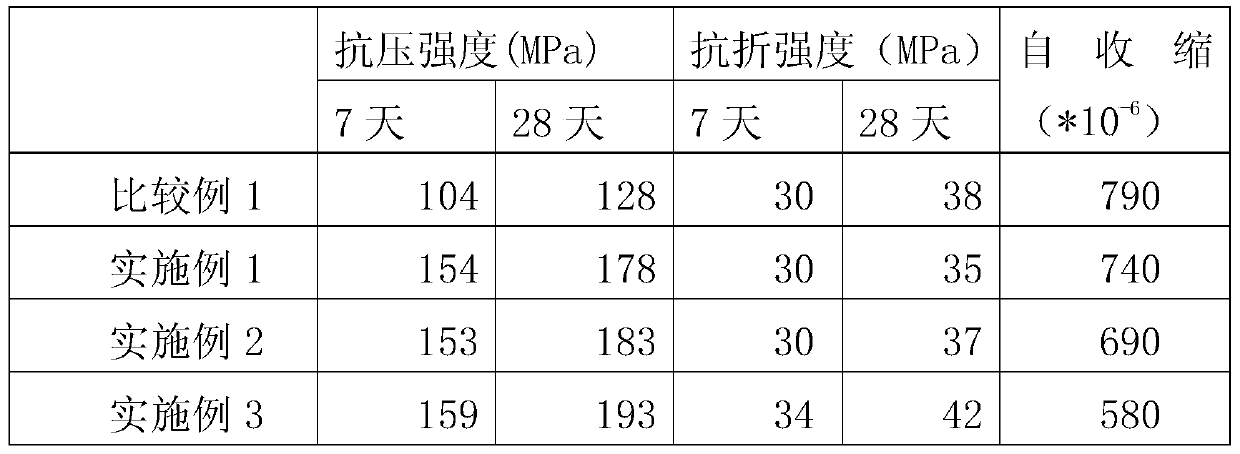

Examples

Embodiment 2

[0027] The only difference from Example 1 is that the expansion agent is calcium oxide gypsum (category B) 30kg / m 3 .

Embodiment 3

[0029] The only difference from Example 1 is that the expansion agent is calcium sulfoaluminate CSA (category C) 30kg / m 3 .

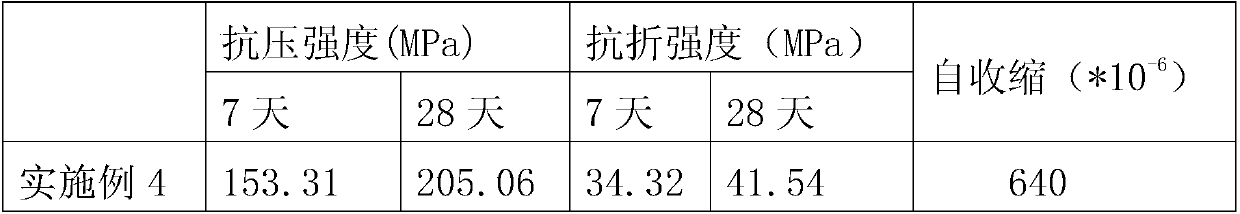

Embodiment 4

[0040] Weighing and taking materials: Portland cement (Jidong Dunshi 52.5R cement, mineral composition is C 3 S5 1.8%, C 2 S 24.08%, C 3 A 7.0%, C 4 AF11.98%, specific surface area 448m 2 / kg, apparent density 3.15g / cm 3 )977kg / m 3 , high-strength admixture (active SiO 2 Mass ratio is 68%, CaO mass ratio is 20%, SO 3 The mass ratio is 8%, Al 2 o 3 Mass ratio is 1.6%) 246kg / m 3 , fine aggregates include quartz river sand and silica sand, of which quartz river sand (apparent density 2.71g / cm 3 , water absorption 0.11%) 271kg / m 3 , silica sand (apparent density 2.87g / cm 3 )747kg / m 3 , 34.57kg / m of polycarboxylate high-performance water reducer with a solid content of 22% 3 , non-ionic surfactant type defoamer 1.8kg / m 3 , calcium oxide expansion agent is 46kg / m 3 , steel fiber (tensile strength 2850MPA, aspect ratio 80, density 7.85g / cm3) volume content 1.75%, organic fiber (polypropylene fiber, density 0.91 / cm3, aspect ratio 450, bundled monofilament, elongation at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com