Diisobutyl phthalate neutralizing, washing and dealcoholizing integrated reaction kettle

A diisobutyl phthalate and reaction kettle technology, which is applied in the field of reaction kettles, can solve problems such as inconvenient operation, high equipment cost, and large floor space, and achieve improved heat preservation effect, easy separation of alcohol esters, and improved Effect of Alcohol Vaporization Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

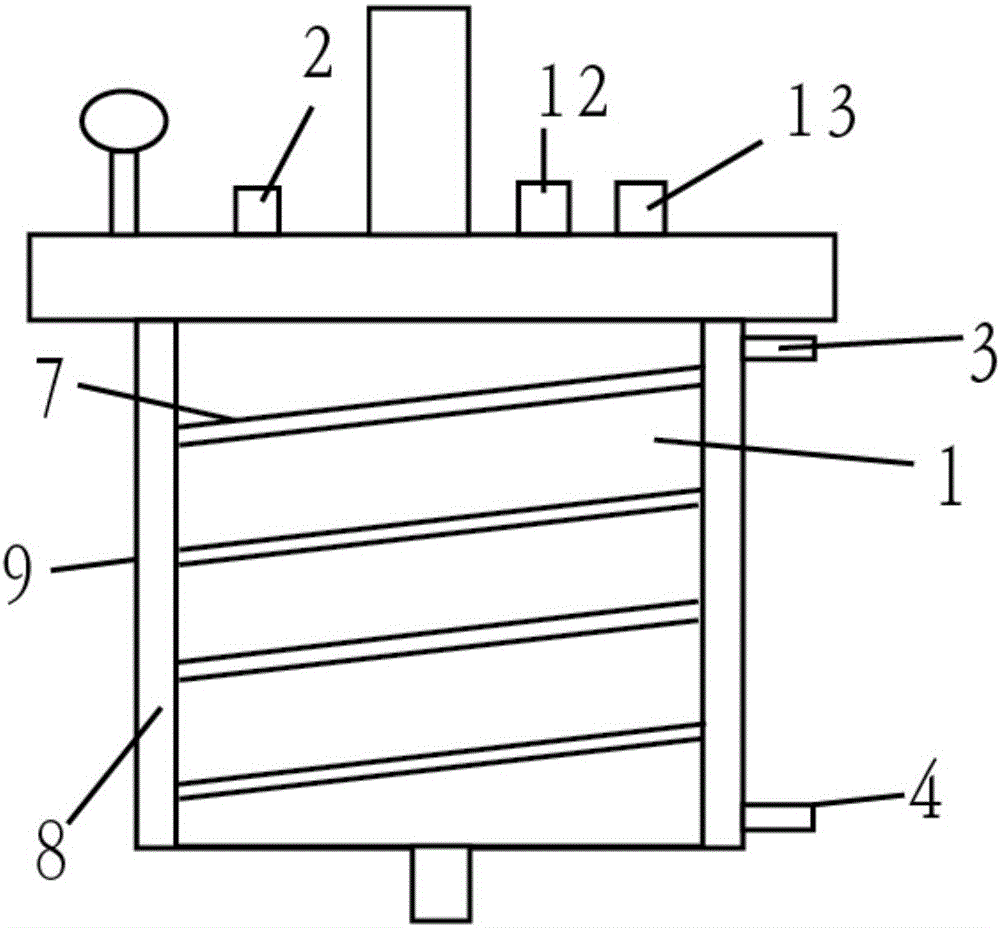

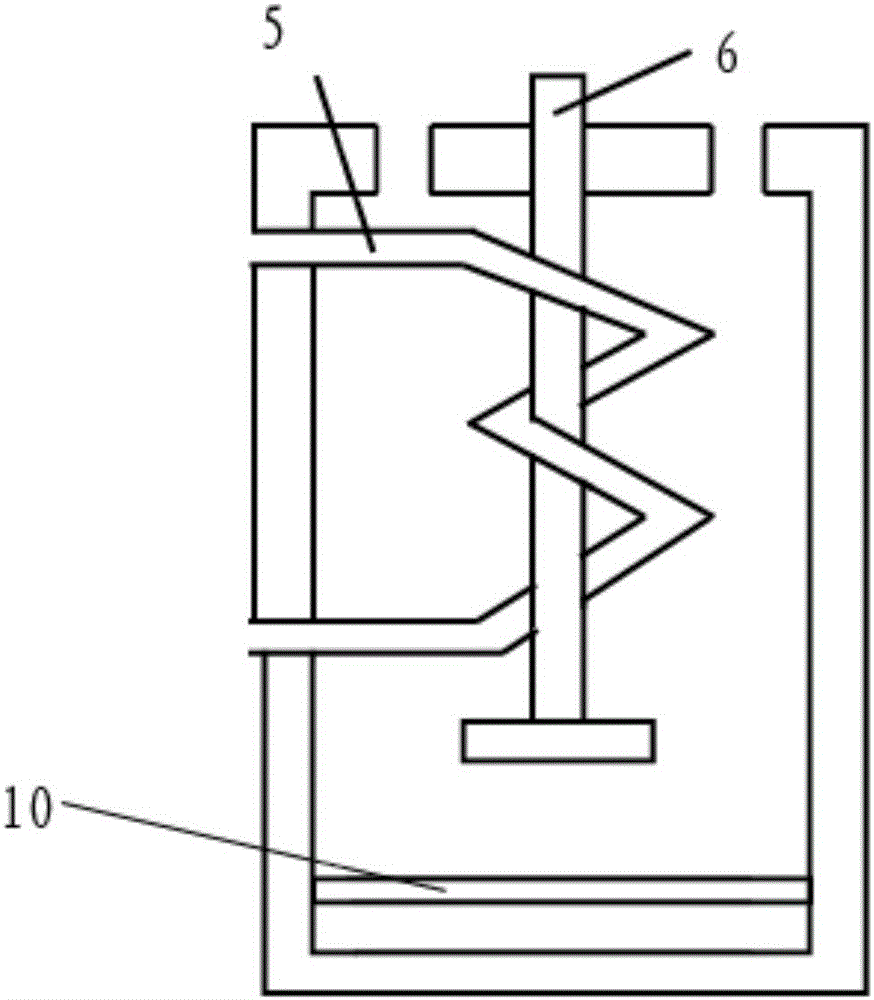

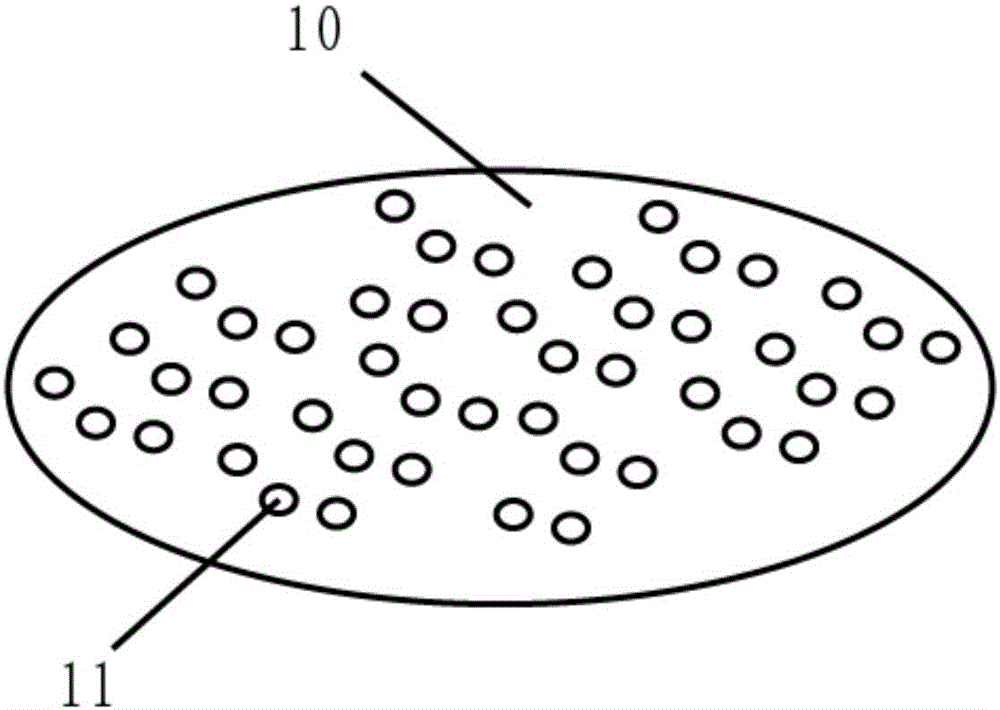

[0021] Such as Figure 1-3 As shown, the present invention discloses a diisobutyl phthalate neutralization, water washing, and dealcoholization integrated reaction kettle, which includes a kettle body 1, an alcohol outlet 2 is arranged on the top of the kettle body 1, and an alcohol outlet 2 is arranged on the kettle body 1. The steam inlet 3 and the steam outlet 4, the steam inlet 3 is located in the upper part of the kettle body 1 and the steam outlet 4 is located in the lower part of the kettle body 1 or the steam inlet 3 is located in the lower part of the kettle body 1 and the steam outlet 4 is located in the kettle body The upper part of 1. The inner cavity of the kettle body 1 is provided with a steam pipe 5, and the two ends of the steam pipe 5 communicate with the corresponding steam ports.

[0022] Preferably, the steam pipe 5 is in a spiral shape.

[0023] Preferably, the steam pipe 5 spirals with the stirring shaft 6 of the kettle body 1 as the axis.

[0024] Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com