Implanted titanium mesh realizing temperature self-adjustment and preparation method of implanted titanium mesh

A self-regulating, titanium mesh technology, applied in the field of medical devices, can solve problems such as chronic brain damage, subcutaneous effusion, and head sensitivity, and achieve the effects of alleviating discomfort, reducing chronic damage, and reducing the generation of subcutaneous effusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

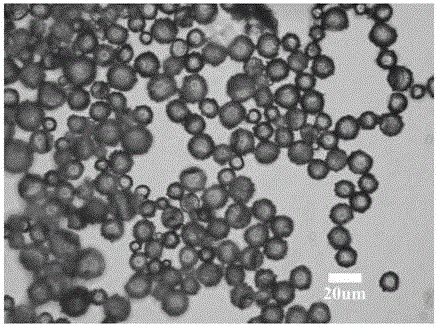

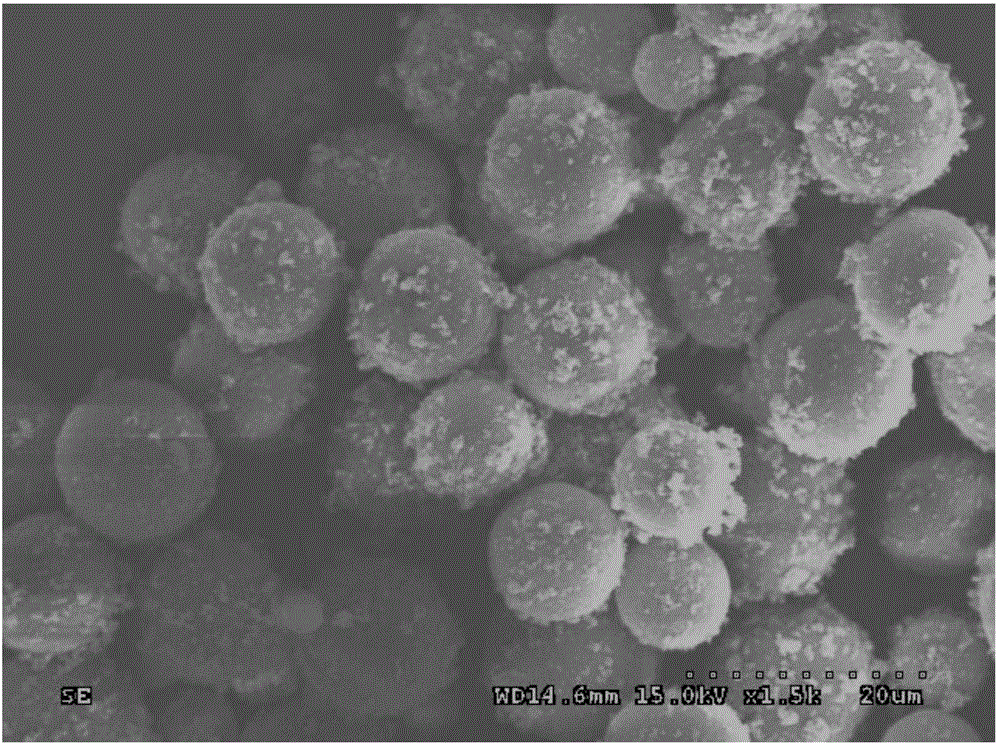

[0037] Prepare 5g of emulsifier sodium dodecylsulfonate aqueous solution with a mass fraction of 5%, add 30ml of water to dilute, add 1g of vinyltriethoxysilane coupling agent, adjust the pH value to 6, and then add High-efficiency tissue section paraffin at 37°C (Shanghai Shenhua Paraffin Co., Ltd.) 4g, styrene 2g, cross-linking agent divinylbenzene 1g, initiator azobisisobutyronitrile 0.06g, heat up to 40°C for 5 minutes, stir Mix the water phase and the oil phase evenly, raise the temperature to 70° C., and use a high-speed shearer to shear and emulsify for 2 minutes at a speed of 12,000 revolutions per minute (rpm) to obtain an oil-in-water emulsion. Transfer the emulsion to a three-necked flask preheated in advance, inject nitrogen gas, mechanically stir at 200 rpm, polymerize at 70°C for 8 hours, cool the reaction system to room temperature, suction filter, wash, and dry to obtain a core-shell structure phase transition In the microcapsule, the shell layer is polystyrene...

Embodiment 2

[0042] Prepare 4g of an aqueous solution of emulsifier sodium dodecylsulfonate with a mass fraction of 10%, add 30 milliliters of water for dilution, add 1g of vinyl tris (β-methoxyethoxy) silane coupling agent, and adjust the pH value to 7. Heat up to 45°C to obtain a water phase; heat 10g of paraffin wax with a melting point of 37°C to 50°C and mix it with 0.06g of initiator azobisisobutyronitrile (AIBN), and stir to disperse AIBN in paraffin to obtain an oil phase; Then the oil phase and the water phase were emulsified in a high-speed shear machine at a speed of 12000r / min for 2min, transferred to a three-necked flask, fed with nitrogen, and heated to 70°C to obtain emulsion a.

[0043] Prepare an aqueous solution of emulsifier sodium dodecylsulfonate with a mass fraction of 10%, and adjust the pH value to 4.5; mix 2g of styrene and 1g of divinylbenzene evenly, and then add 30g of sodium dodecylsulfonate aqueous solution with a pH value of 4.5 , using a high-speed shearing ...

Embodiment 3

[0049] Add 7g of emulsifier polystyrene-maleic acid (HSMA) aqueous solution with a mass fraction of 15% to 75mL of distilled water for dilution, add 1g of γ-aminopropyltriethoxysilane coupling agent, add 10g of High-efficiency tissue section paraffin (Shanghai Shenhua Paraffin Co., Ltd.), heated at 70°C until the paraffin was completely melted, and emulsified at a high speed of 12000r / min for 10 minutes to obtain an emulsion. Add dropwise an aqueous solution of 2 g of a urea-formaldehyde resin (UF) prepolymer (Shanghai Aladdin Biochemical Technology Co., Ltd.) with a concentration of 20% by mass in the emulsion, adjust the pH value of the system to 3.5-4.0, and react at a constant temperature of 70° C. for 3 hours. The system was cooled to room temperature, suction filtered, washed, and dried to obtain phase change energy storage microcapsule samples. The core-shell structure phase change microcapsules can be obtained by incubating the phase change energy storage microcapsule ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com