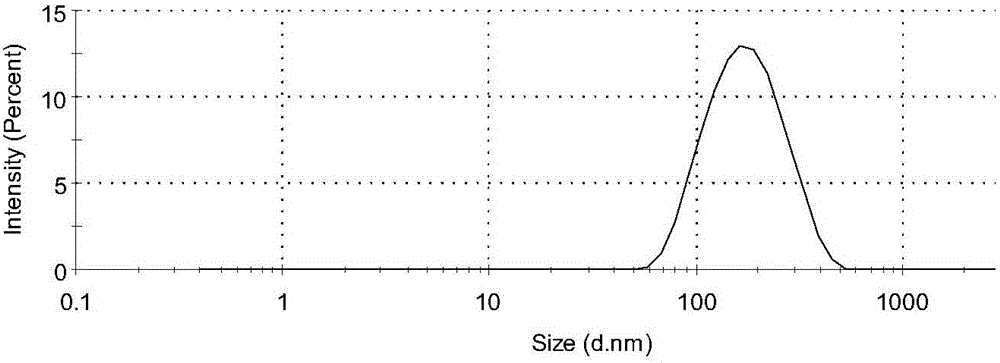

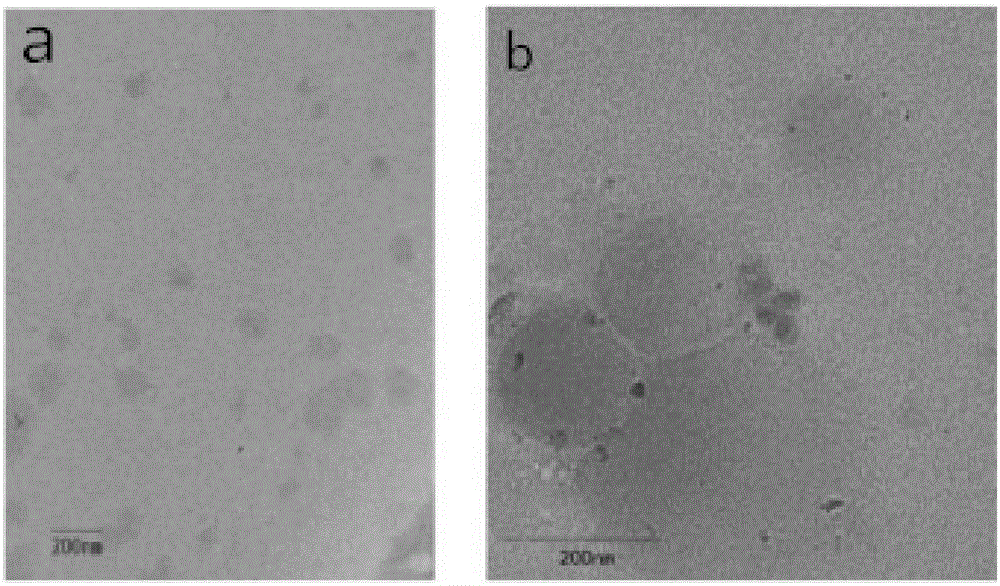

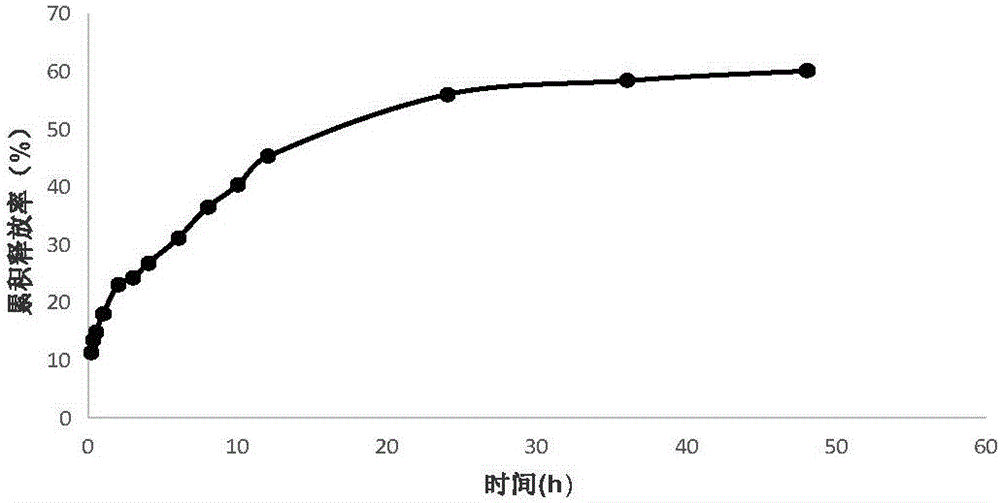

Preparation method and applications of gambogic acid self-assembled polymer nanoparticles

A technology of gambogic acid and self-assembly, applied in the field of medicine and chemical industry, can solve the problems of poor stability, low drug loading, low encapsulation rate, etc., and achieve good stability, good biocompatibility, and high encapsulation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of embodiment 1 gambogic acid self-assembled polymer nanoparticle

[0027] The preparation method is as follows:

[0028] 1) Polymer material preparation: 0.04mol polyethylene glycol 6000, 0.001mol ε-caprolactone, 0.0001mol stannous octoate and 5ml toluene were added to a three-necked bottle, stirred under mechanical stirring and N 2 Under protection, react in an oil bath at 130°C for 12 hours; after the reaction, the reaction product is naturally cooled to room temperature, and the toluene is spun out; the product is dissolved in dichloromethane, and after the product is completely dissolved, it is slowly dropped into a large amount of cold petroleum ether. Precipitate, filter with suction, dissolve the precipitate with dichloromethane, slowly drop into petroleum ether, repeat the operation, and filter to obtain a white product, which is vacuum-dried at 40°C to obtain a polymer material.

[0029] 2) Put 40mg of gambogic acid into eggplant-shaped...

Embodiment 2

[0033] The preparation of embodiment 2 gambogic acid self-assembled polymer nanoparticles

[0034] The method is the same as in Example 1, the ultrasonic power is selected to be 315W, but the number of ultrasonic waves is changed to 1 time, 2 times, 3 times, 4 times, 5 times, 6 times, and each time is 2 minutes, and the gambogic acid self-assembled polymer nanoparticles are measured The particle size, PDI, encapsulation efficiency, and drug loading are shown in Table 2.

[0035] Table 2

[0036]

[0037] It can be seen from Table 2 that when the ultrasonic time is increased from 2 min to 4 min, the encapsulation efficiency and drug loading are the highest. Continuing to increase the ultrasonic time, the encapsulation efficiency decreased instead. Moreover, if the ultrasonic time is too long, the polymer skeleton will be broken, the particles will be broken, the solution will be unstable, and some coagulation will occur. Therefore, the optimal time is 4 minutes.

Embodiment 3

[0038] The preparation of embodiment 3 gambogic acid self-assembled polymer nanoparticles

[0039] The method is the same as in Example 1, the ultrasonic power is selected to be 315W, and the hydration time is changed to 2h, 4h, 6h, and 8h respectively, and the particle size, PDI, encapsulation efficiency, and drug loading of gambogic acid self-assembled polymer nanoparticles are measured As in Table 3.

[0040] table 3

[0041]

[0042] As can be seen in Table 3, the hydration time increased from 2h to 8h. At 4h, the encapsulation efficiency and drug loading reached the highest, and the hydration time was 4h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com