A Method for Obtaining the Uniaxial Stress-Strain Relationship of Materials by Compression of Disk Specimen

A technology of strain relationship and material list, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of difficult testing and difficulty in obtaining mechanical properties of different regions, and achieves easy popularization and application, simple formulas, and material saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

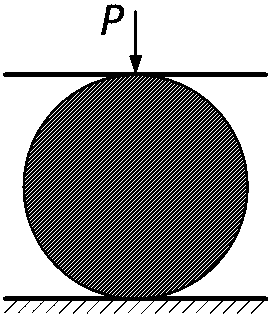

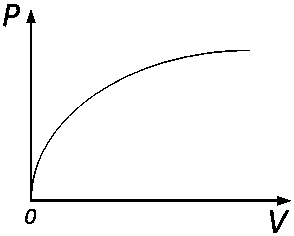

[0032] In the technical solution of the present invention, based on the derivation of equivalent energy theory and a small amount of finite element simulation, a technical theoretical system for obtaining the uniaxial stress-strain relationship of materials by using disk compression is proposed.

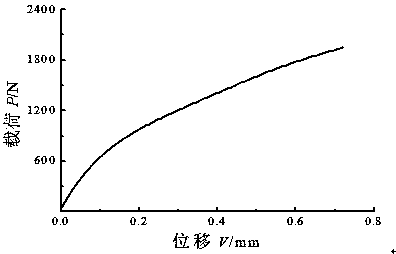

[0033] The compression test was carried out on the DP600 dual-phase steel micro-disc sample (radius 2.5 mm and thickness 1 mm) by using the MTS809 25KN electro-hydraulic servo material testing machine, as shown in Figure 4 As shown, the test data is zero-point corrected, the nonlinear segment is fitted with a power law, and the fitted exponent and coefficient are brought into equation (2) to solve the simultaneous equation, and the mechanical property parameter σ of the material or component can be obtained y and n, put into formula (3) to get the constitutive relation curve of the material. That is, the uniaxial true stress-strain curve of DP600 dual-phase steel obtained by the tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com