High-efficiency, energy-saving and environment-friendly pre-combustion burner

A high-efficiency, energy-saving and environmentally friendly technology, applied in the burner, combustion type, combustion method and other directions, can solve the problems of increasing the emission of flue gas harmful substances, uneven distribution of air-fuel ratio, insufficient fuel combustion, etc. The effect of reducing energy consumption and accelerating warm-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

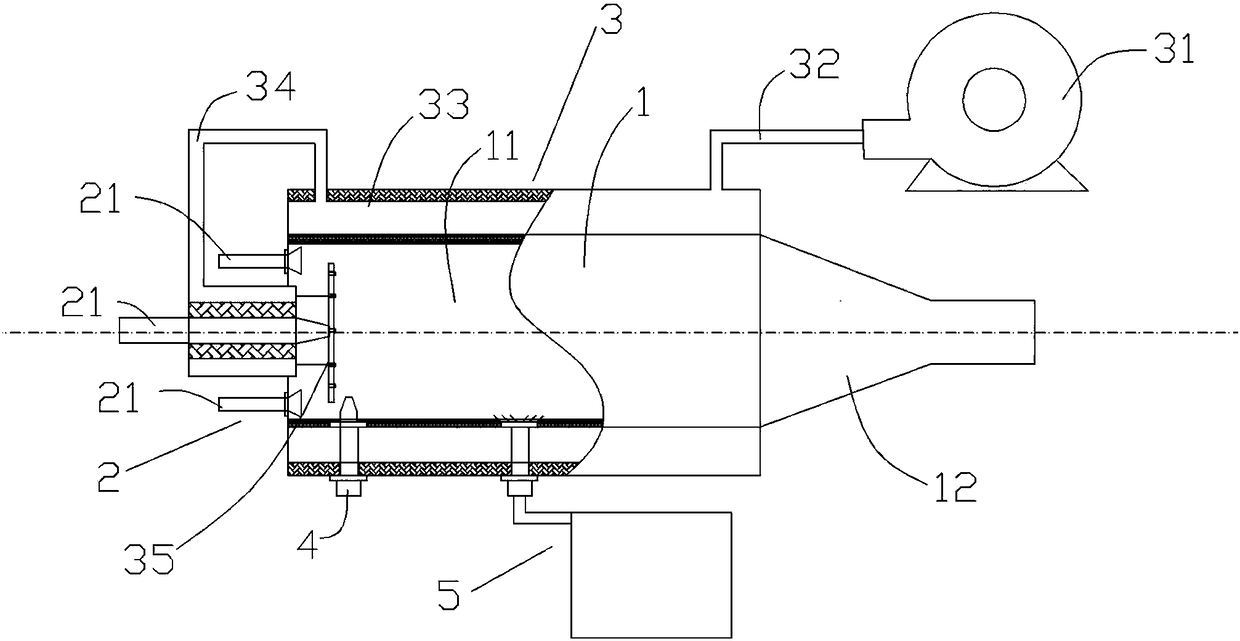

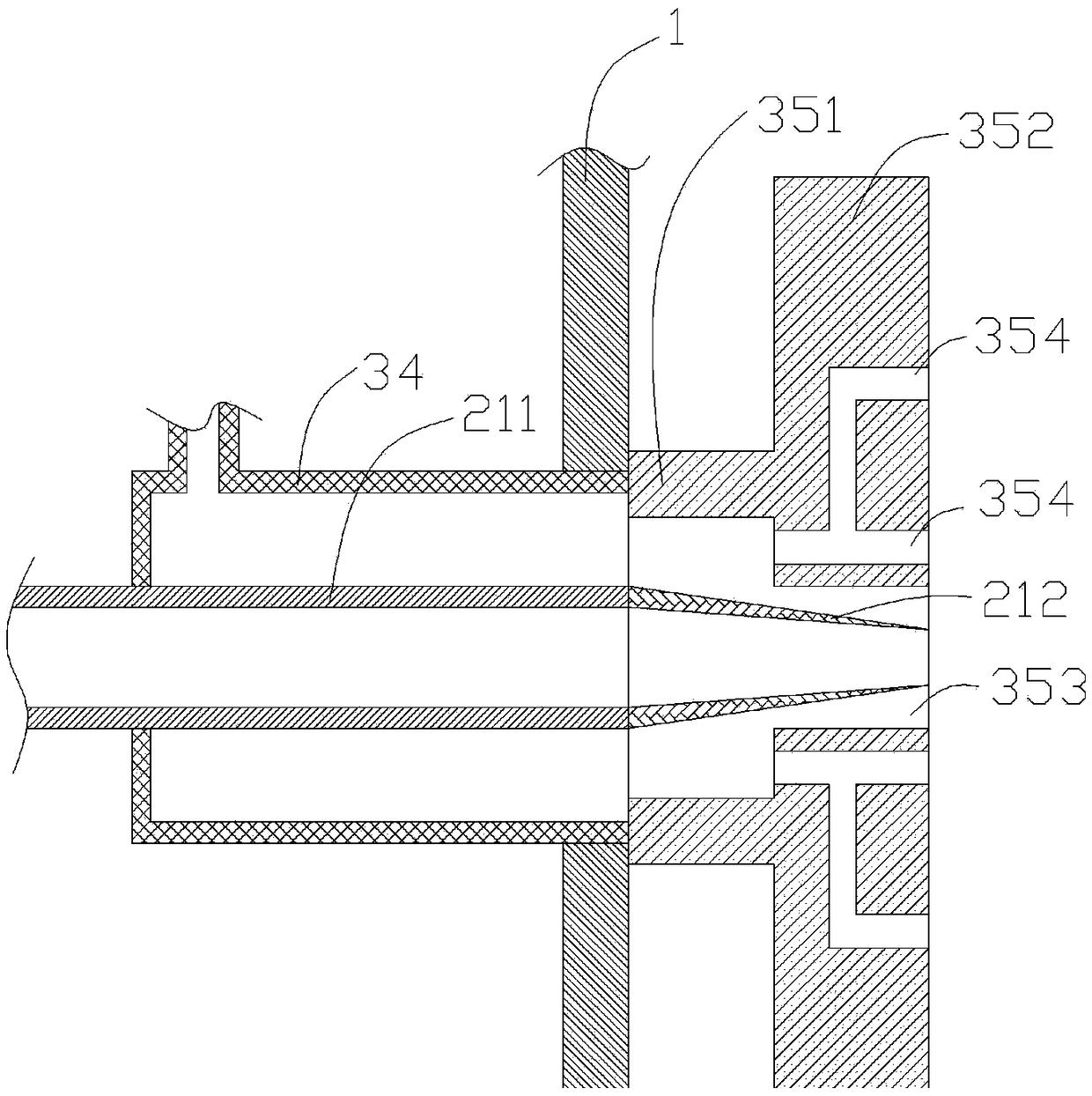

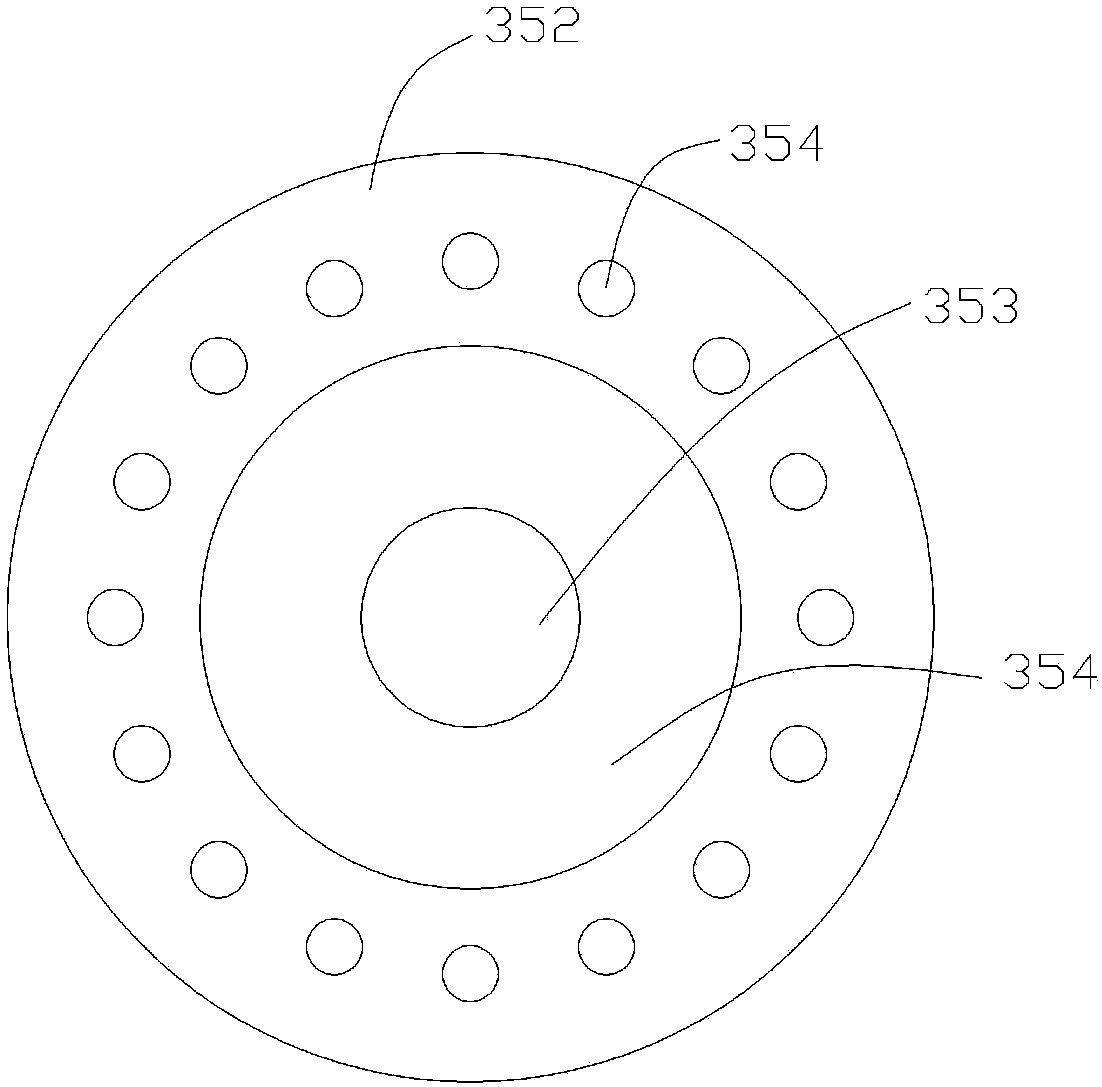

[0023] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

[0024] Such as Figure 1-3 As shown, the high-efficiency, energy-saving and environment-friendly pre-combustion burner of the present invention includes a pre-combustor 1, a fuel supply assembly 2, an air supply assembly 3, an igniter 4 and an oxygen enrichment device 5, wherein:

[0025] The pre-combustor 1 is made of metal material. The pre-combustor 1 includes a pre-combustion chamber 11 and an air injection chamber 12 which communicate with each other. The pre-combustion chamber 11 is a cylinder arranged horizontally; the air injection chamber 12 is stepped, and its left end is a large end , each step of the jet chamber 12 is a horizontal cylinder, the right end of the pre-combustion chamber 11 communicates with the left end of the jet chamber 12, and the right end of the jet chamber 12 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com