Preparation method of cationic nano-microcrystalline cellulose reinforced papermaking surface sizing agent

A technology of surface sizing agent and nano-crystallite, which is applied in the field of pulp and paper making, can solve problems affecting the rheological properties of emulsions, sizing properties, adsorption and agglomeration, etc., and achieve the effects of potential application value, cost control reduction, and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Based on edible starch, pipette amylase at an amount of 150-200 ppm, add it to a certain amount of distilled water, and slowly add edible starch at a stirring speed of 700-800 rpm to make it completely dispersed. And put it in an 80ºC water bath, stir and gelatinize for 25 minutes; finally, heat it in a 130ºC oil bath for 3 minutes to inactivate the enzyme; keep it warm at 60ºC and follow the amount of 5% (as edible starch As the benchmark), the cationic styrene-acrylic emulsion was pipetted and uniformly dispersed for 30 min at a stirring speed of 400 rpm.

[0026] Do not add cationic nano-microcrystalline cellulose sol, directly add distilled water until the solid content of all samples is 10%, that is, get a papermaking surface sizing agent with zero addition; add a defoamer to the system as needed, and use aluminum sulfate The pH of the solution was adjusted to 4~5; finally, the sample was placed in a 60 ºC water bath to keep warm, and stirred continuously to disper...

Embodiment 2

[0029] Based on edible starch, pipette amylase at an amount of 150-200 ppm, add it to a certain amount of distilled water, and slowly add edible starch at a stirring speed of 700-800 rpm to make it completely dispersed. And put it in an 80ºC water bath, stir and gelatinize for 25 minutes; finally, heat it in a 130ºC oil bath for 3 minutes to inactivate the enzyme; keep it warm at 60ºC and follow the amount of 5% (as edible starch As the benchmark), the cationic styrene-acrylic emulsion was pipetted and uniformly dispersed for 30 min at a stirring speed of 400 rpm.

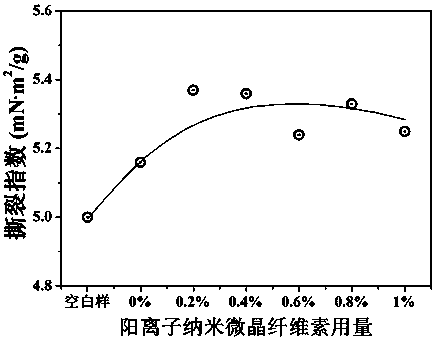

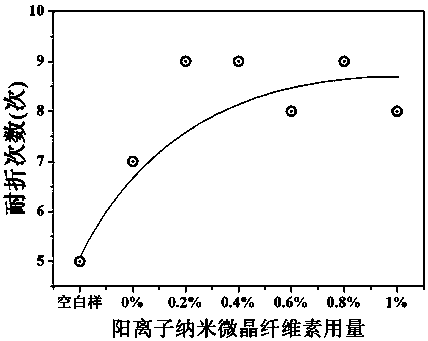

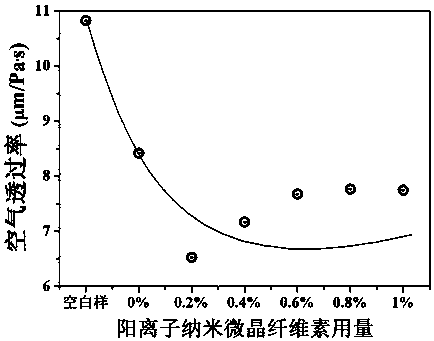

[0030] Based on the amount of edible starch, 0.2% cationic nanocrystalline cellulose sol was added to the above system, and distilled water was added until the solid content of all samples was 10%, that is, cationic nanocrystalline cellulose-enhanced surface-making applications were obtained. Glue; add defoamer dropwise to the system as needed, and adjust the pH to 4~5 with aluminum sulfate solution; finally, put t...

Embodiment 3

[0033] Based on edible starch, pipette amylase at an amount of 150-200 ppm, add it to a certain amount of distilled water, and slowly add edible starch at a stirring speed of 700-800 rpm to make it completely dispersed. And put it in an 80ºC water bath, stir and gelatinize for 25 minutes; finally, heat it in a 130ºC oil bath for 3 minutes to inactivate the enzyme; keep it warm at 60ºC and follow the amount of 5% (as edible starch As the benchmark), the cationic styrene-acrylic emulsion was pipetted and uniformly dispersed for 30 min at a stirring speed of 400 rpm.

[0034]Based on the amount of edible starch, 0.4% cationic nano-microcrystalline cellulose sol was added to the above system, and distilled water was added until the solid content of all samples was 10%, that is, a cationic nano-microcrystalline cellulose-enhanced papermaking surface coating was obtained. Glue; add defoamer dropwise to the system as needed, and adjust the pH to 4~5 with aluminum sulfate solution; fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com