Device for fast sedimentation of filtered juice of sugar refinery and control method of device

A juice filtering and fast technology, which is applied in the sugar industry, can solve the problems affecting the normal operation of the fast settler, unstable heating temperature of the filtered juice, and poor operation of the fast settler, so as to shorten the solid-liquid separation time and stabilize the addition of auxiliary materials Accurate, increase the effect of sinking or rising speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

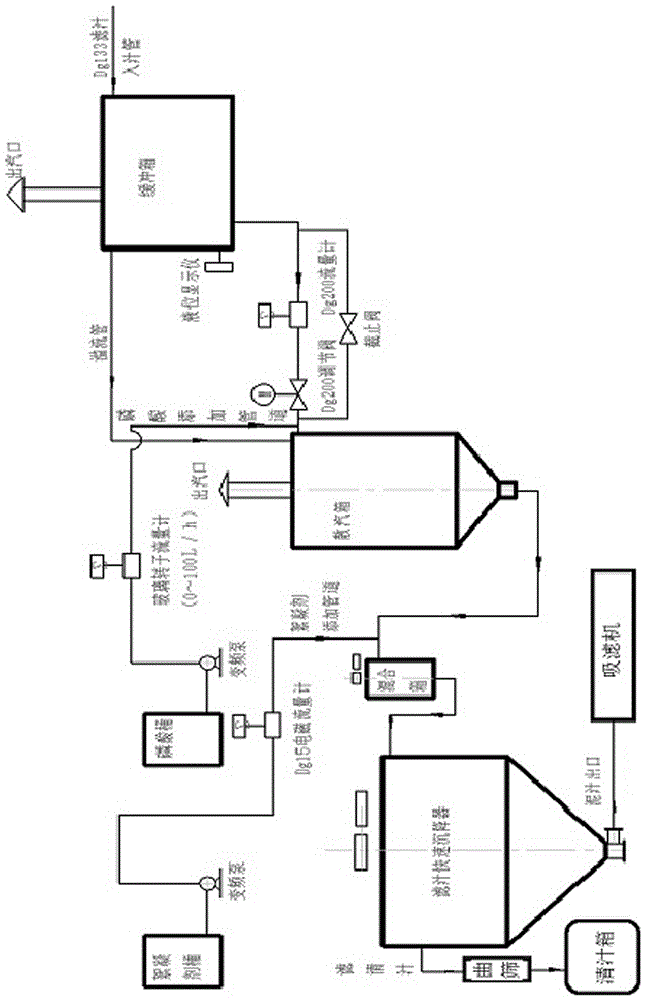

[0051] A device for quick settling of filtered juice in a sugar factory, the device includes a buffer tank, a diffuser tank, a mixing tank and a quick settler for filtered juice, the buffer tank is connected with the diffuser tank through a flow meter and a regulating valve, and is placed in the buffer tank A cut-off valve is set between the outlet and the inlet of the diffuser tank, and an overflow pipe is provided on the upper part of the buffer tank to connect with the diffuser tank; after the diffuser tank is connected to the mixing tank, it is connected to the juice filter fast settler.

[0052] An electric regulating valve is provided at the entrance of the buffer tank, and a pressure transmitter is provided at the bottom of the buffer tank.

[0053] The top of the buffer tank is provided with a steam outlet.

[0054] The buffer tank is provided with a liquid level indicator.

[0055] A phosphoric acid addition pipeline is provided at the entrance of the diffuser box, a...

Embodiment 2

[0064] A device for quick settling of filtered juice in a sugar factory, the device includes a buffer tank, a diffuser tank, a mixing tank and a quick settler for filtered juice, the buffer tank is connected with the diffuser tank through a flow meter and a regulating valve, and is placed in the buffer tank A cut-off valve is set between the outlet and the inlet of the diffuser tank, and an overflow pipe is provided on the upper part of the buffer tank to connect with the diffuser tank; after the diffuser tank is connected to the mixing tank, it is connected to the juice filter fast settler.

[0065] An electric regulating valve is provided at the entrance of the buffer tank, and a pressure transmitter is provided at the bottom of the buffer tank.

[0066] The top of the buffer tank is provided with a steam outlet.

[0067] The buffer tank is provided with a liquid level indicator.

[0068] A phosphoric acid addition pipeline is provided at the entrance of the diffuser box, a...

Embodiment 3

[0077] A device for quick settling of filtered juice in a sugar factory, the device includes a buffer tank, a diffuser tank, a mixing tank and a quick settler for filtered juice, the buffer tank is connected with the diffuser tank through a flow meter and a regulating valve, and is placed in the buffer tank A cut-off valve is set between the outlet and the inlet of the diffuser tank, and an overflow pipe is provided on the upper part of the buffer tank to connect with the diffuser tank; after the diffuser tank is connected to the mixing tank, it is connected to the juice filter fast settler.

[0078] An electric regulating valve is provided at the entrance of the buffer tank, and a pressure transmitter is provided at the bottom of the buffer tank.

[0079] The top of the buffer tank is provided with a steam outlet.

[0080] The buffer tank is provided with a liquid level indicator.

[0081] A phosphoric acid addition pipeline is provided at the entrance of the diffuser box, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com