Conversion Of Natural Gas To Liquid Form Using A Rotation/separation System In A Chemical Reactor

A technology for chemical conversion, liquefaction of natural gas, applied in the field of converting natural gas into liquid using a rotation/separation system in a chemical reactor, which can solve problems such as economic constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

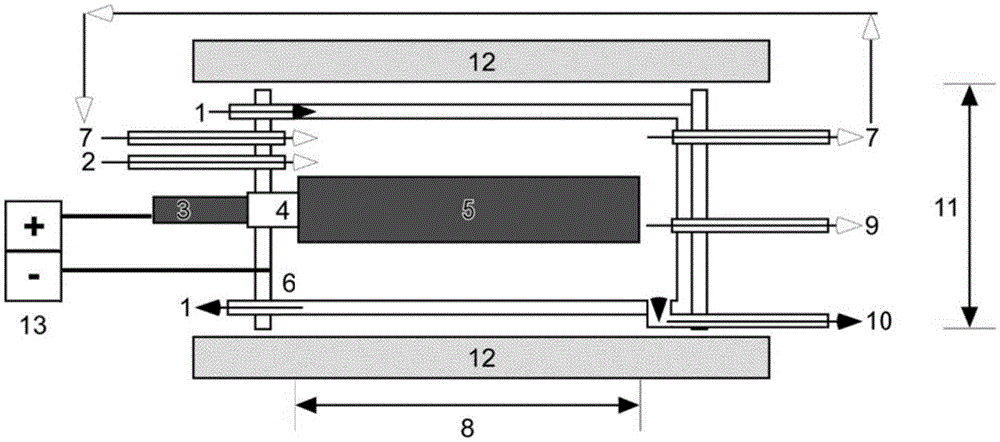

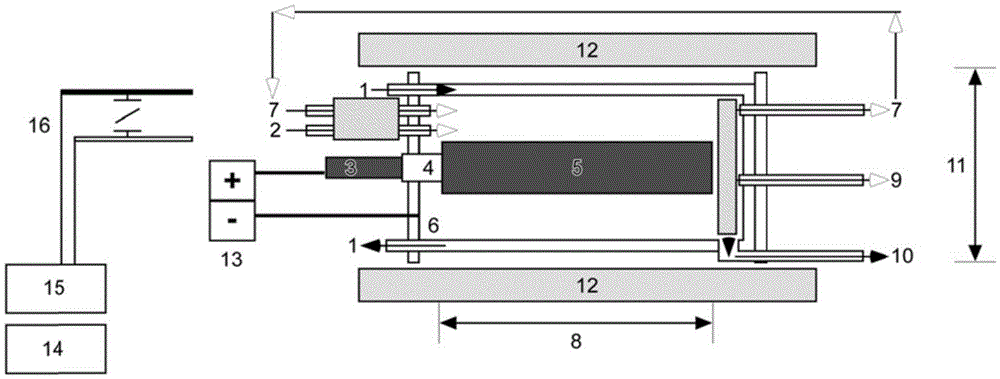

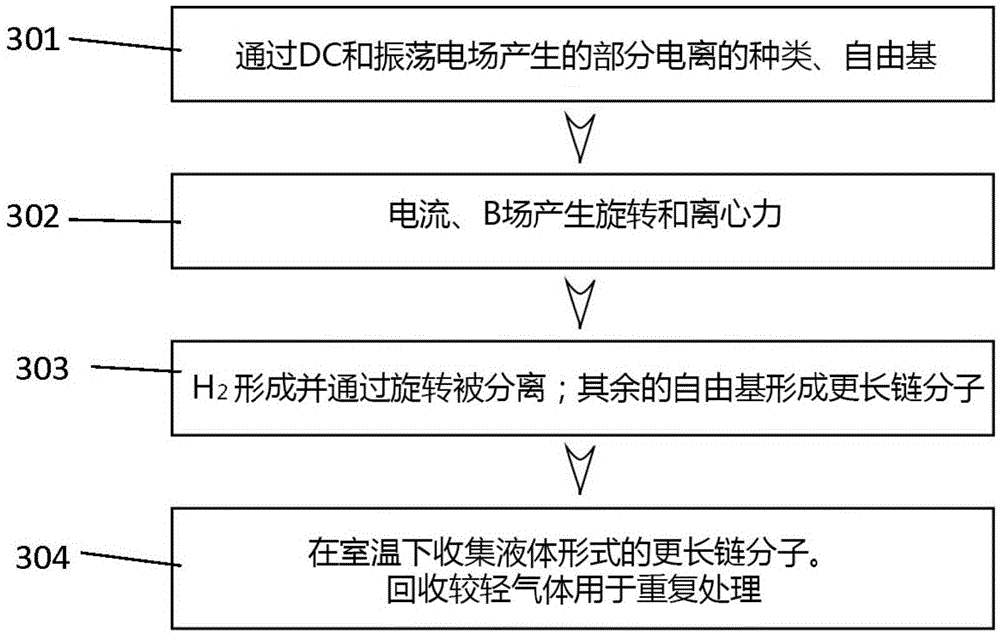

[0022] Natural gas molecules (such as methane or CH 4 , which are made to form "radical" species (e.g. CH 3 、CH 2 、CH 1 etc. (collectively referred to as CH X ))) react readily with other radical hydrocarbons to form longer chain hydrocarbons. Pentane (C 5 h 12 ) is the first liquid hydrocarbon formed by this chain extension at room temperature. The feedstock natural gas in combination with an electron donating species such as argon is capable of spinning it in the presence of a magnetic field and passing an electric current. Due to the Lorentz force, proper rotation is achieved without any mechanical movement. The rotation of the gas in the chamber causes heavy chemical species to separate from light species due to centrifugal force. The reacted natural gas undergoes carbon chain elongation. This process results in the formation of pentane species, which are non-volatile and separate from lighter species due to centrifugal force and precipitation. The lighter and vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com