High flame retardant polyurethane foam thermal insulation material and preparation method thereof

A technology of polyurethane foam and thermal insulation material is applied in the field of organic composite materials to achieve the effect of improving fire resistance and thermal insulation performance and high flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

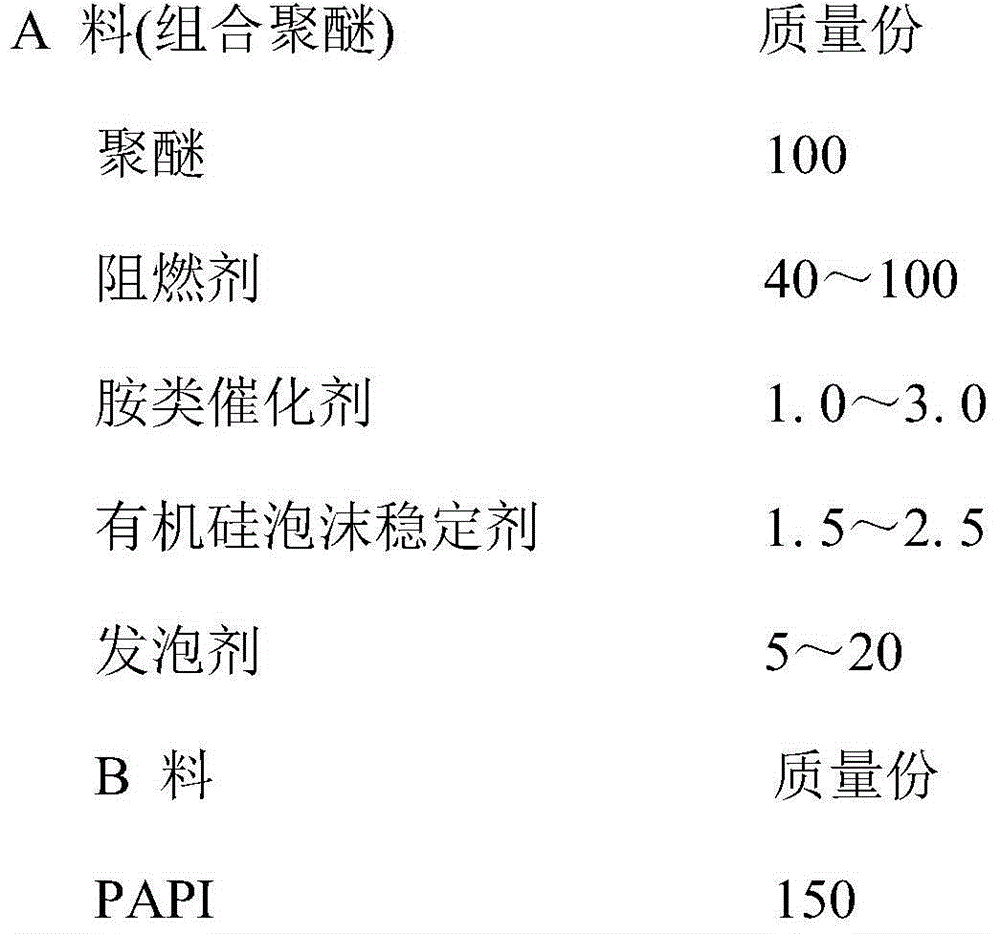

[0020] Composition of the invention

[0021]

[0022] First, mix material A evenly, and then add material B. After the mixed material is stirred quickly and fully, it is poured into the pre-prepared mold, and left for a few days after aging, and various performance tests are performed.

[0023] Use 1mm thick tinplate and high flame-retardant PU hard foam to make a composite plate of 120mm×120mm×50mm, place it at the mouth of the muffle furnace, align the outer iron sheet with the outer mouth of the furnace, and test the surrounding gaps with rock wool. The thermocouple measures the temperature of the outer iron sheet of the composite plate (referred to as the plate back temperature). The test is carried out to simulate the fire resistance test of building components, which is GB9978 "Fire Resistance Test Method for Building Components", and the oxygen index reaches 30.

Embodiment 2

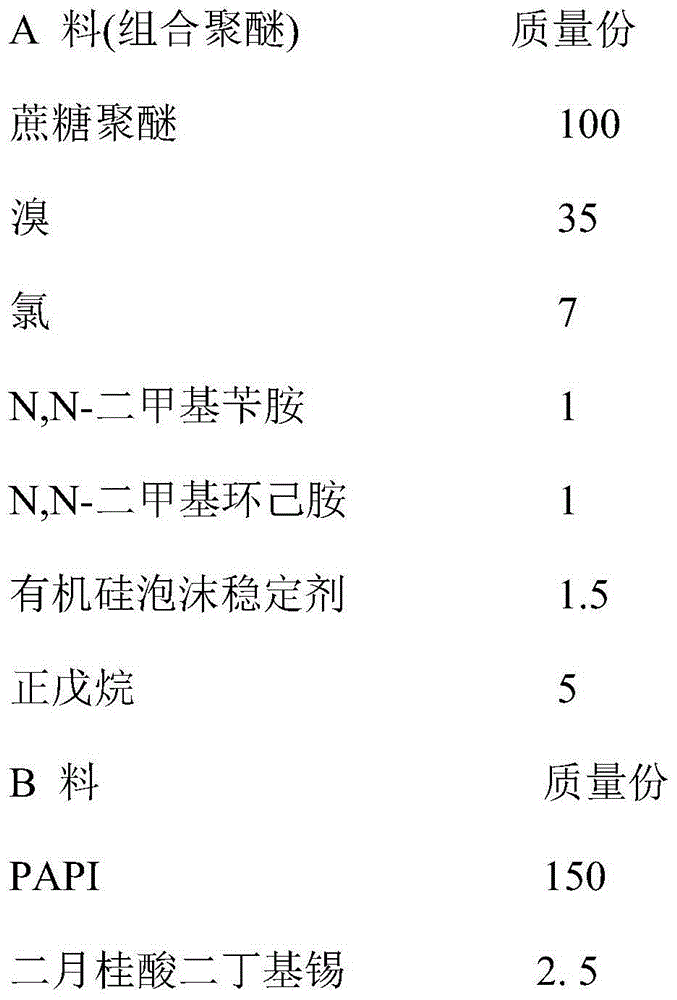

[0025] Composition of the invention

[0026]

[0027] First, mix material A evenly, and then add material B. After the mixed material is stirred quickly and fully, it is poured into the pre-prepared mold, and it is left for a few days after aging, and various performance tests are carried out.

[0028] Use 1mm thick tinplate and high flame-retardant PU hard foam to make a composite plate of 120mm×120mm×50mm, place it at the mouth of the muffle furnace, align the outer iron sheet with the outer mouth of the furnace, and test the surrounding gaps with rock wool. The thermocouple measures the temperature of the outer iron sheet of the composite plate (referred to as the plate back temperature). The test is carried out to simulate the fire resistance test of building components, which is GB9978 "Fire Resistance Test Method of Building Components", and the oxygen index reaches 32.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com