Plasma-etching-resistant ceramic body, manufacturing method thereof, and plasma-etching equipment

An etching equipment and ion etching technology, applied in the field of ceramic materials, can solve problems such as pollution, high-purity alumina ceramics are easily corroded by plasma, and damage wafers, etc., to achieve easy control of process conditions and improve plasma corrosion resistance The effect of high performance and wafer yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

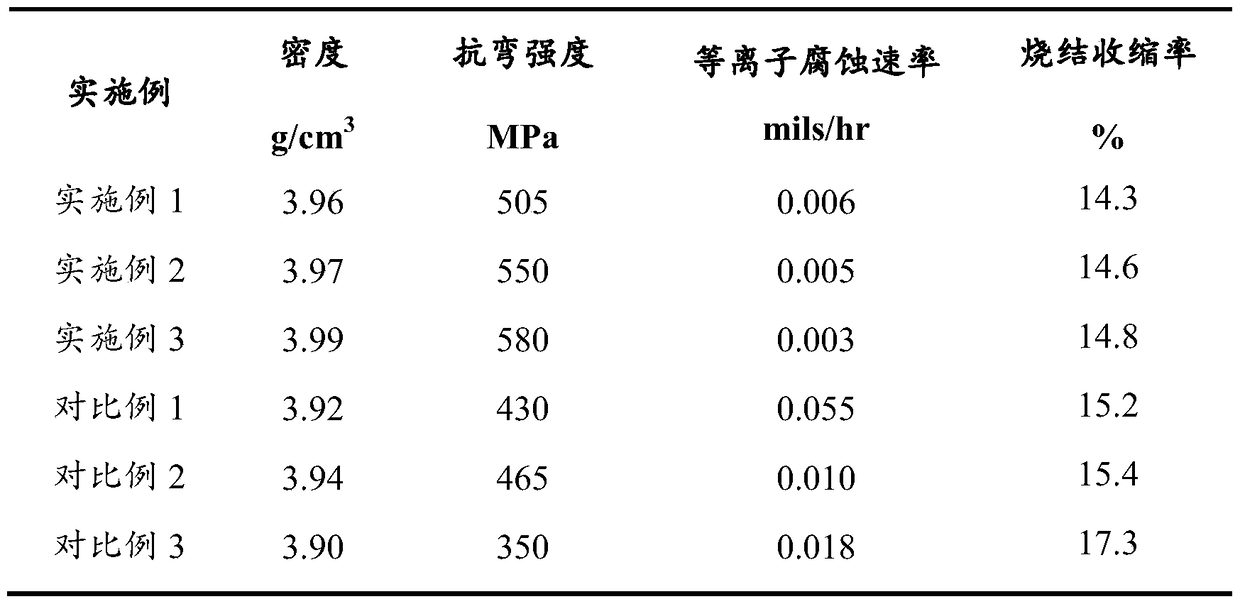

Examples

preparation example Construction

[0022] On the other hand, the embodiment of the present invention also provides a preparation method of the above-mentioned plasma etching resistant ceramic body of the embodiment of the present invention. In one embodiment, the method for preparing a plasma-etching resistant ceramic body according to the embodiment of the present invention includes the following steps:

[0023] Step S01: obtaining nano-alumina powder;

[0024] Step S02: The nano-alumina powder provided in step S01 is molded and then placed in a protective atmosphere for sintering.

[0025] In one embodiment, in the above step S01, the alumina powder contains unavoidable impurity components, and the mass content of the impurity components is not more than 0.001%, or the mass content of the alumina is not less than 99.999%. As mentioned above, since some impurities remain more or less in the production process of the alumina raw material, the content of the inevitable impurities is controlled not to be greate...

Embodiment 1

[0038] Embodiment 1 provides a plasma-etched ceramic body and a preparation method thereof. The plasma-etched ceramic body is obtained by firing alumina powder after compression molding, wherein the alumina powder has a purity of 99.999% and an average particle size of 200 nanometers.

[0039] The preparation method of the plasma etching ceramic body is as follows:

[0040] S11: Obtain nano-alumina powder with a purity of 99.999% and an average particle size of 200 nanometers;

[0041] S12: Put the nano-alumina powder into the metal mold for compression molding and then sintering; wherein, the metal mold is made of a wear-resistant metal mold; before the nano-alumina powder is loaded into the metal mold, the inner wall of the mold and the upper and lower The die punch is coated with boron nitride solution as a lubricant to form a continuous and uniform solid film on the inside of the die cavity to facilitate pressing and demoulding; the pressing pressure during the molding pr...

Embodiment 2

[0043] Embodiment 2 provides a plasma-etched ceramic body and a preparation method thereof. The plasma-etched ceramic body is obtained by firing alumina powder after compression molding, wherein the alumina powder has a purity of 99.999% and an average particle size of 200 nanometers.

[0044] The preparation method of the plasma etching ceramic body is as follows:

[0045] S11: Obtain nano-alumina powder with a purity of 99.999% and an average particle size of 200 nanometers;

[0046] S12: Put the nano-alumina powder into the metal mold for compression molding and then sintering; wherein, the metal mold is made of a wear-resistant metal mold; before the nano-alumina powder is loaded into the metal mold, the inner wall of the mold and the upper and lower The die punch is coated with boron nitride solution as a lubricant to form a continuous and uniform solid film on the inside of the die cavity to facilitate pressing and demoulding; the pressing pressure during the molding pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com