Erosion-resistant fused zirconium corundum brick for glass furnace and preparation method thereof

A glass kiln and zirconium corundum brick technology, applied in the field of refractory materials, can solve the problems of difficult industrialization, hindering material movement, and extremely high equipment requirements, and achieve a reasonable internal crystal phase structure, prolong service life, and high corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

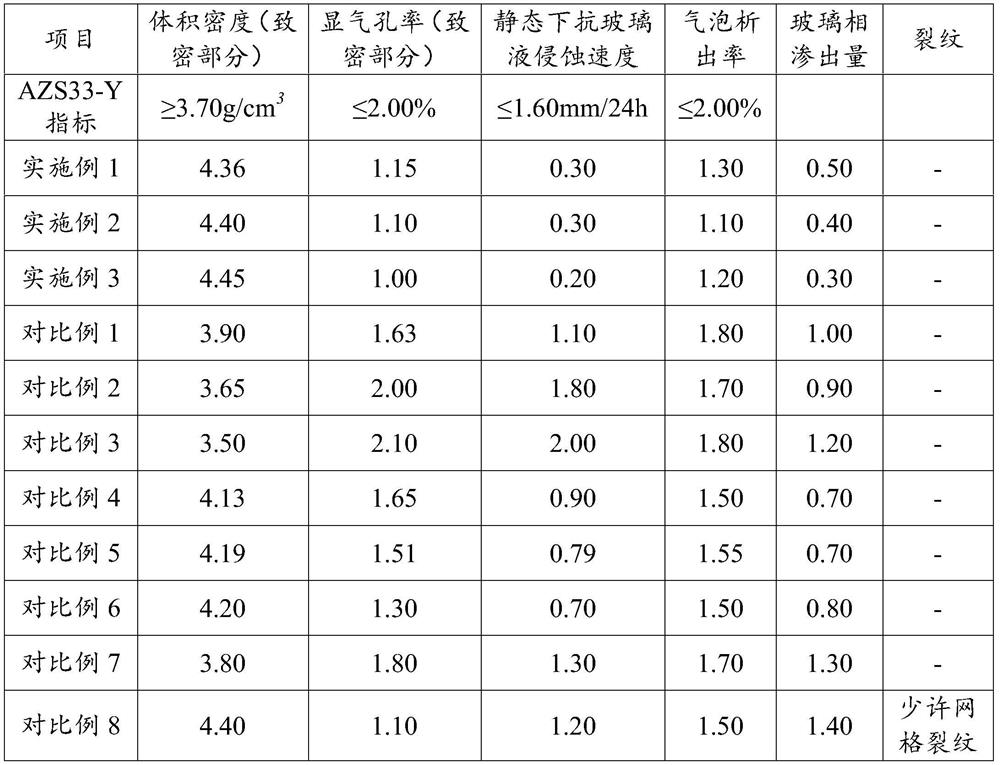

Examples

Embodiment 1

[0032] An erosion-resistant fused zirconia corundum brick for a glass furnace, comprising the following components in mass percentage: 43.0% zircon sand, 51.0% alumina powder, 1.4% soda ash, 3.8% zirconia, 0.2% rare earth, andalusite powder 0.2%, hydroxypropyl methylcellulose 0.4%.

[0033] Its preparation method steps are as follows:

[0034]S1: Use computer 3D modeling sub-drawings to issue product mold drawings. The model workshop uses a foam cutting machine to make models according to the drawings, and the sand mold workshop makes sand molds through model sanding; sand molds use self-hardening sand technology to make reasonable blank processing. The casting workshop puts the sand mold into a special insulation box, fills it with hollow silicon-aluminum ball insulation material, and then uses a vibrator to vibrate the insulation material and wait for casting;

[0035] S2: After mixing zircon sand, alumina powder, zirconia, soda ash, and hydroxypropyl methylcellulose throug...

Embodiment 2

[0044] An erosion-resistant fused zirconia corundum brick for a glass furnace, comprising the following components in mass percentage: 41.0% zircon sand, 48% alumina powder, 2.0% soda ash, 5.9% zirconia, 0.7% rare earth, andalusite powder 0.8%, hydroxypropyl methylcellulose 1.6%.

[0045] Its preparation method steps are as follows:

[0046] S1: Use computer 3D modeling sub-drawings to issue product mold drawings. The model workshop uses a foam cutting machine to make models according to the drawings, and the sand mold workshop makes sand molds through model sanding; sand molds use self-hardening sand technology to make reasonable blank processing. The casting workshop puts the sand mold into a special insulation box, fills it with hollow silicon-aluminum ball insulation material, and then uses a vibrator to vibrate the insulation material and wait for casting;

[0047] S2: After mixing zircon sand, alumina powder, zirconia, soda ash, and hydroxypropyl methylcellulose through...

Embodiment 3

[0056] An erosion-resistant fused zirconia corundum brick for a glass furnace, which consists of the following components in mass percentage: 41.9% zircon sand, 49.4% alumina powder, 2.0% soda ash, 4.6% zirconia, 0.4% rare earth, andalusite Powder 0.6%, hydroxypropyl methylcellulose 1.1%.

[0057] Its preparation method steps are as follows:

[0058] S1: Use computer 3D modeling sub-drawings to issue product mold drawings. The model workshop uses a foam cutting machine to make models according to the drawings, and the sand mold workshop makes sand molds through model sanding; sand molds use self-hardening sand technology to make reasonable blank processing. The casting workshop puts the sand mold into a special insulation box, fills it with hollow silicon-aluminum ball insulation material, and then uses a vibrator to vibrate the insulation material and wait for casting;

[0059] S2: After mixing zircon sand, alumina powder, zirconia, soda ash, and hydroxypropyl methylcellulos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com