A kind of preparation method of boron carbide powder for grinding liquid

A technology of boron carbide powder and grinding liquid, applied in the field of materials, can solve the problems of poor quality of boron carbide powder, etc., and achieve the effects of reducing grinding cost, fast grinding rate and high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Prepare boron carbide raw materials, the weight purity is 95%, according to the atomic ratio B:C=4.1, the volume percentage of needle-shaped and flaky crystals is ≤1%, and the particle size is ≤500mm;

[0050] The boron carbide raw material is crushed with a Raymond mill to a particle size of 30-120mm to obtain boron carbide scraps;

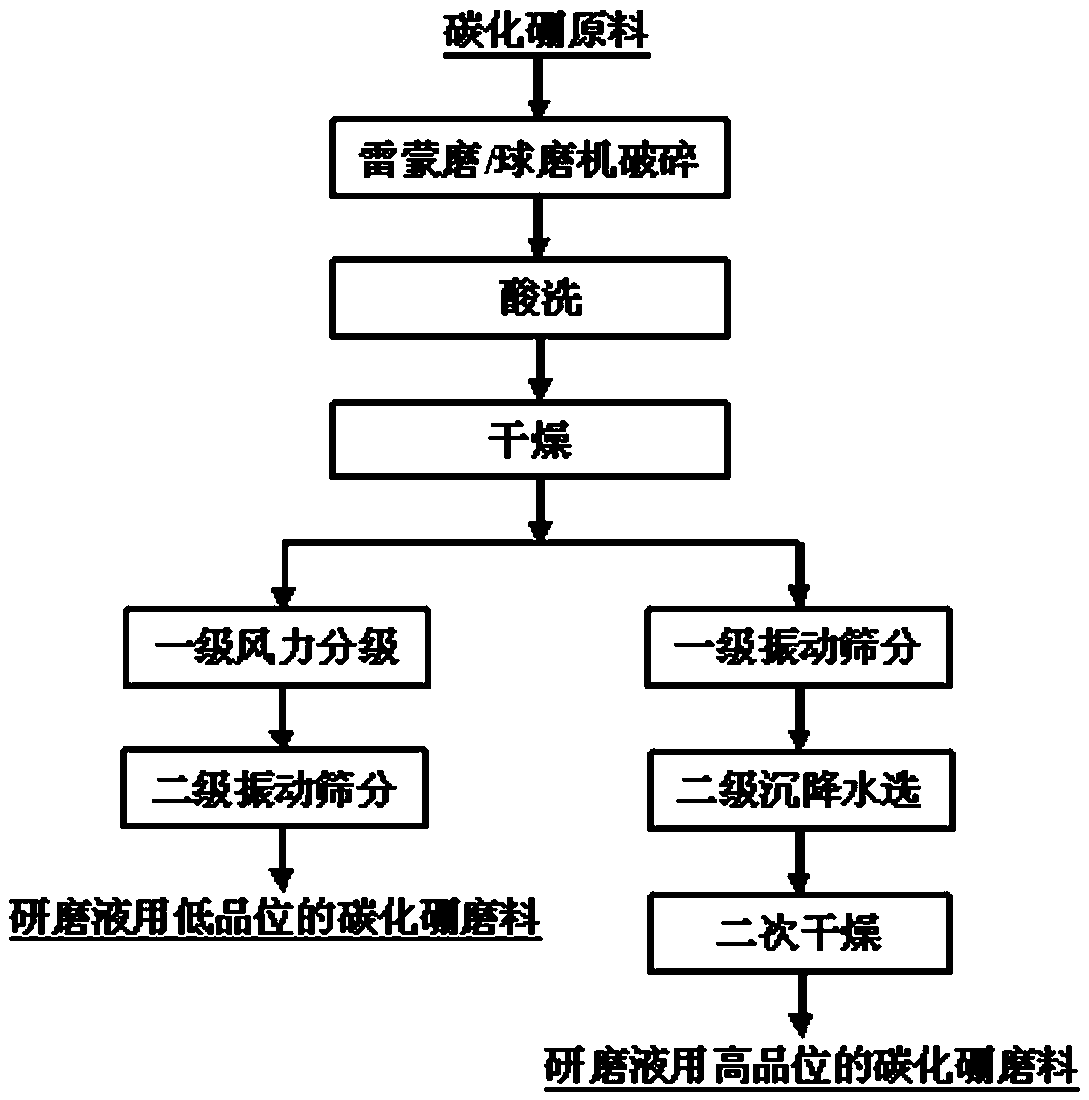

[0051] The boron carbide scraps were pickled until the weight content of Fe was less than or equal to 1%, dried to remove moisture, and then the first-level wind classification and the second-level vibratory screening were carried out. A total of four groups of experiments were carried out; among them, the speed of the classification wheel during the first-level wind classification It is 300~1000r / min. After the first-level wind classification, four groups of first-level wind-classified materials with particle sizes of 50-90mm, 60-100mm, 70-110mm and 80-130mm are obtained. After the second-level vibratory screening, the particle size is 58~...

Embodiment 2

[0059] Method is with embodiment 1, and difference is:

[0060] (1) The weight purity of boron carbide raw material is 96%, according to the atomic ratio B:C=4.2;

[0061] (2) Use a ball mill to crush the boron carbide raw material to a particle size of 30-120 mm to obtain boron carbide scraps; when the ball mill is crushed, the boron carbide raw material: water: steel ball = 1:2:1, and the ball milling time is 6 hours;

[0062] (3) Pickling boron carbide scraps until the weight content of Fe is ≤1%, drying to remove water, and then performing primary vibration screening, secondary sedimentation water separation and secondary drying, a total of four sets of experiments were carried out; primary vibration After sieving, four groups of primary vibration grading materials with particle sizes of 50~90mm, 60~100mm, 70~110mm and 80~130mm are obtained. And 100~120mm four groups of secondary sedimentation water separation materials, the secondary sedimentation water separation materi...

Embodiment 3

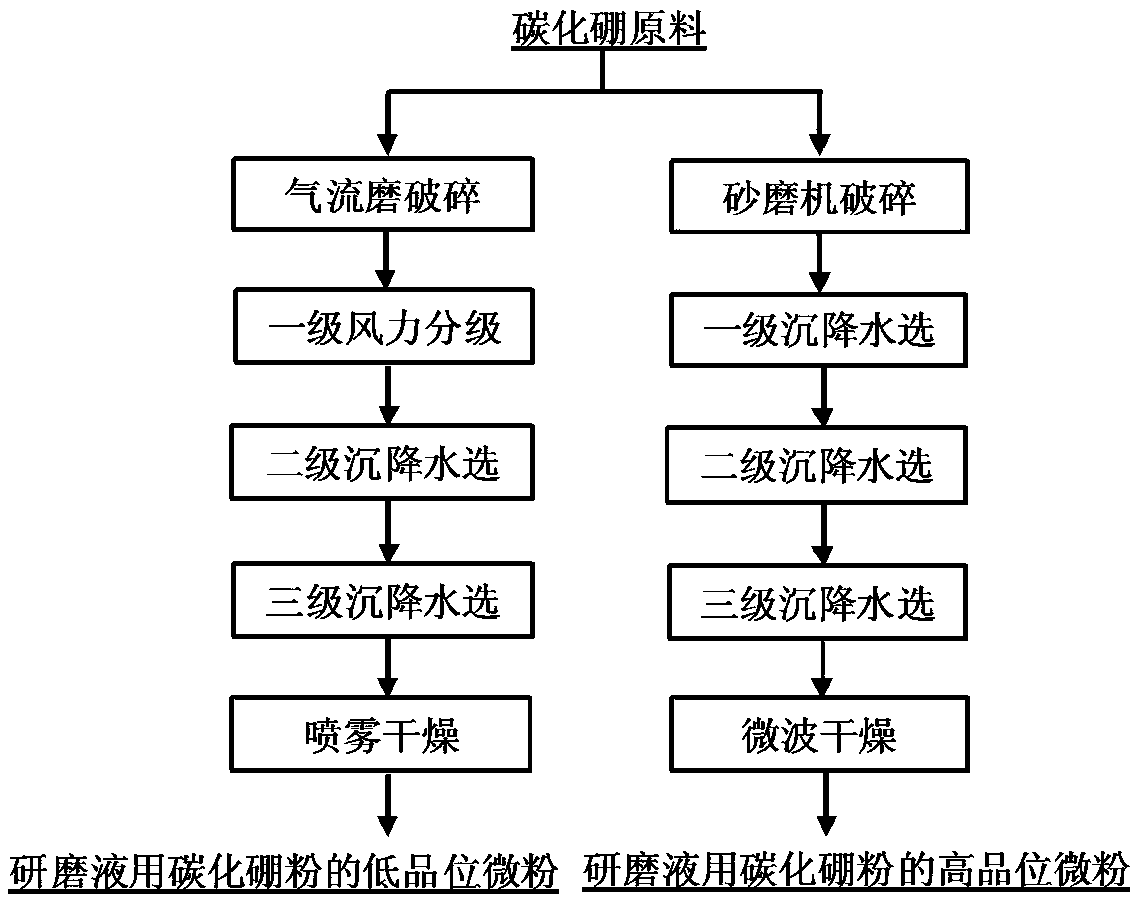

[0072] Method is with embodiment 2, and difference is:

[0073] (1) The weight purity of boron carbide raw material is 97%, according to the atomic ratio B:C=4.3;

[0074] (2) When the ball mill is crushed, the boron carbide raw material: water: steel ball = 1:0.2:0.1 by weight, and the ball milling time is 10h;

[0075] (3) The primary vibration screening time is 3 hours;

[0076] (4) Microwave pickling is used for pickling, the boron carbide scraps are placed in the acid solution, the temperature is controlled at 150°C, and the microwave frequency is 2000MHz; the acid solution used is hydrochloric acid solution, and the acid solution and boron carbide scraps The solid-to-liquid ratio is 1:10g / L, the weight concentration of hydrochloric acid is 20%, and the pickling time is 3h;

[0077] (5) The drying temperature of normal pressure drying is 300°C, and the drying time is 6 hours;

[0078] (6) In the secondary sedimentation water separation, first prepare a slurry with a we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com