Double-shell titanium dioxide catalyst with high photocatalytic hydrogen generation performance and preparation method thereof

A technology of titanium dioxide and black titanium dioxide is applied in the field of semiconductor catalysts and their preparation, which can solve the problems of low hydrogen production and low photocatalytic activity, and achieve the effects of increased hydrogen production, high catalytic activity and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

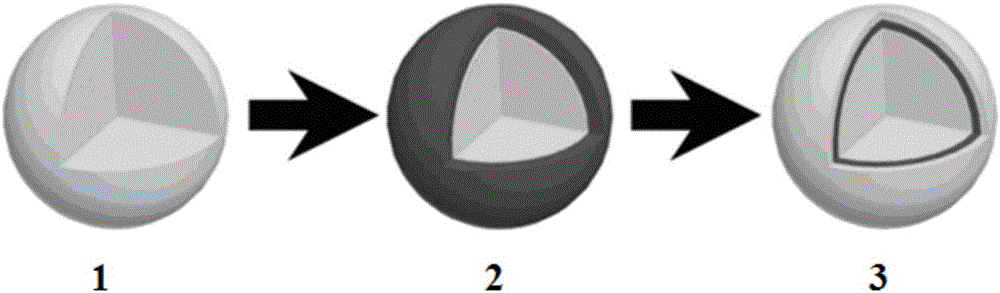

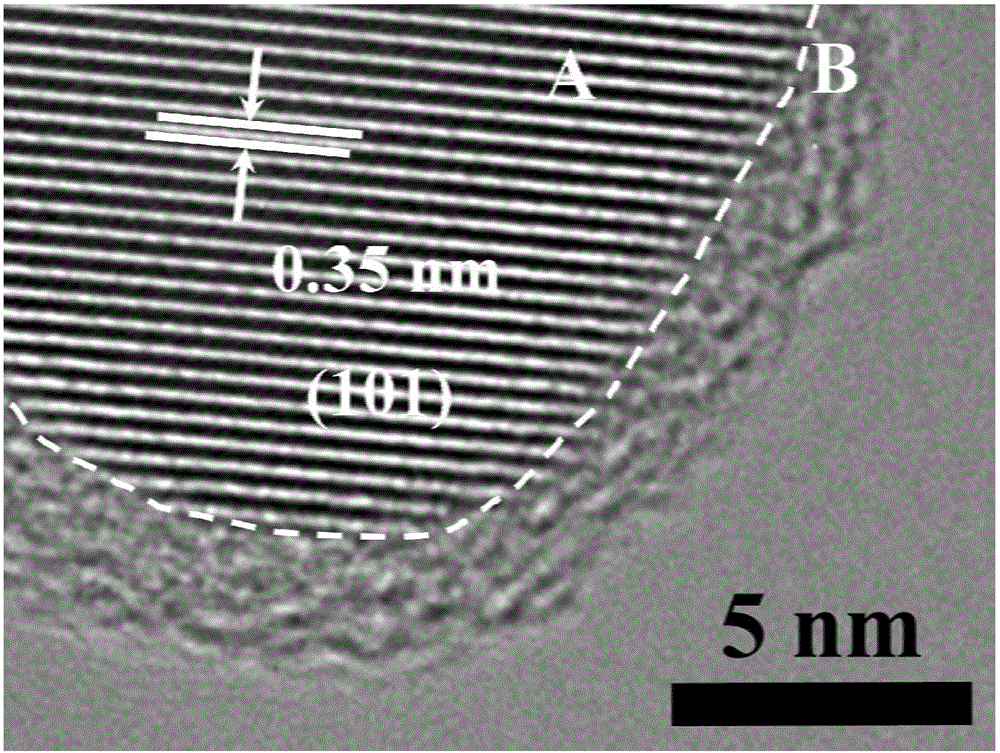

[0021] Embodiment 1: This embodiment is a double-shell titanium dioxide catalyst with high photocatalytic hydrogen production performance, which is composed of a titanium dioxide crystal core, a reduced amorphous layer and an oxidized crystal shell sequentially from the inside to the outside.

[0022] Compared with existing catalysts, the titanium dioxide catalyst with a special core-shell structure in this embodiment has higher catalytic activity and better stability, and is a commercially available titanium dioxide P 25 2.2 times that of black titanium dioxide powder, and 1.3 times that of black titanium dioxide powder. Moreover, it has low cost, no pollution, and can be used in large-scale production.

specific Embodiment approach 2

[0023] Specific embodiment two: This embodiment is a preparation method of a double-shell titanium dioxide catalyst with high photocatalytic hydrogen production performance, which is specifically completed according to the following steps:

[0024] 1. Grinding and mixing: commercial titanium dioxide P 25 and NaBH 4 Mix and grind for 20min to 30min to obtain the mixture; the titanium dioxide P 25 with NaBH 4 The mass ratio is 2:(0.6~0.7);

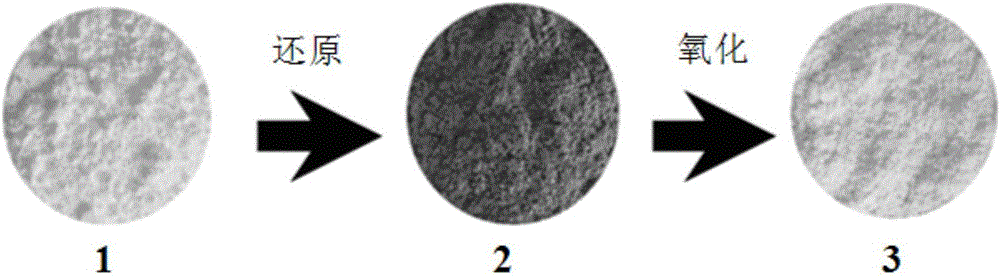

[0025] 2. Annealing reduction: move the mixture into an alumina crucible, then place it in a tube furnace, and raise the temperature from room temperature to 300°C to 400°C at a heating rate of 5°C / min to 10°C / min under a nitrogen atmosphere, and Treat at 300°C-400°C and nitrogen atmosphere for 20min-60min, then cool to room temperature with the furnace to obtain the reacted powder;

[0026] 3. Washing: first wash the reacted powder with ethanol for 2 to 5 times, then wash with deionized water for 2 to 5 times, and finally dry it in a bl...

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment two is: in step one, commercial titanium dioxide P 25 and NaBH 4 Mix and grind for 30min to obtain a mixture; the commercial titanium dioxide P 25 with NaBH 4 The mass ratio is 2:0.66. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com