Silicon solar cell integrated with bypass diode and preparation method of silicon solar cell

A technology of silicon solar cells and bypass diodes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as high system risk, difficult implementation of isolation technology, complex production process, etc., and achieve simple process, enhanced stability and Reliability, Difficulty Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

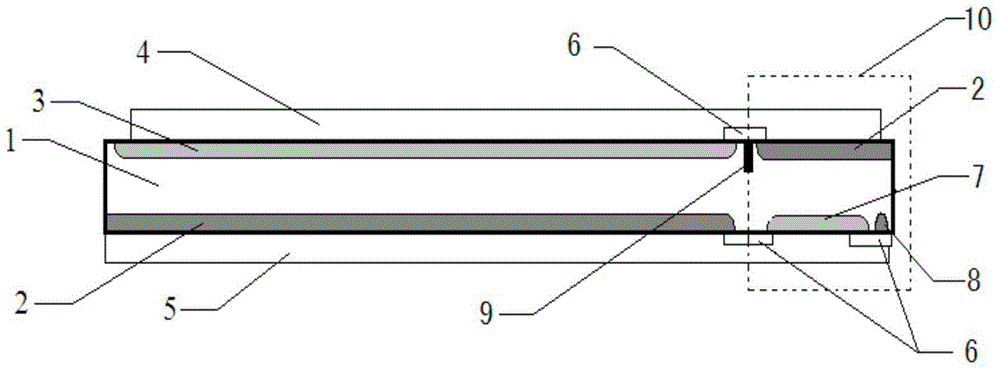

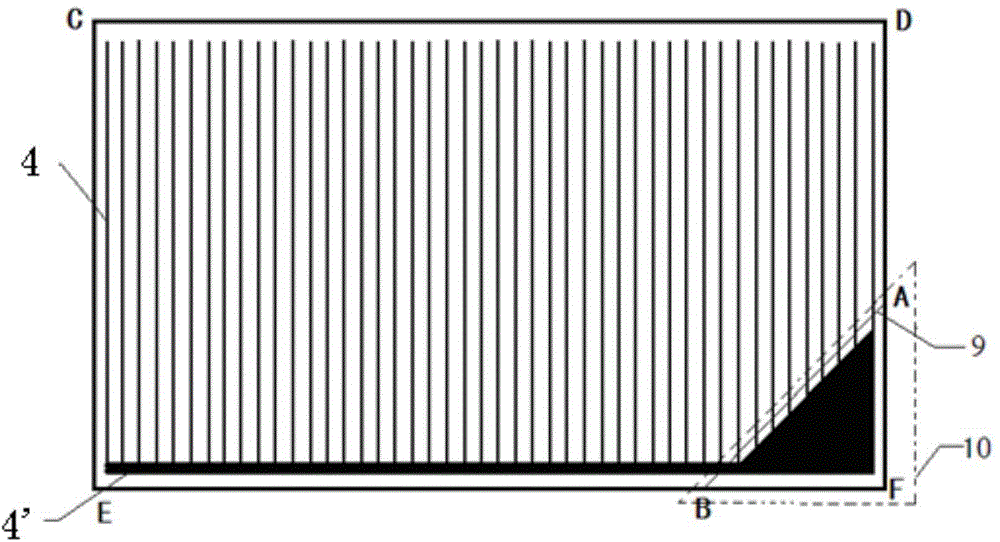

[0054] A silicon solar cell with integrated bypass diodes. The positive and negative poles of the solar cell module are connected in parallel with the bypass diodes. A boron expansion isolation ring is provided between the battery body and the bypass diode, and an oxidation ring is provided on the boron expansion isolation ring. Protection, realize electrode interconnection on the oxidation protection layer. The boron-diffused isolation ring makes the main area of the battery and the bypass diode isolated through the reciprocal PN junction in the ring; the boron diffusion makes the isolation area a P + area, the P + On the one hand, the region forms a P / N junction with the N-type material of the bypass diode, and uses the photovoltaic effect of the semiconductor to generate a photo-generated voltage; on the other hand, the P + It forms a P / N junction with the N-type region of the main battery area, and the two PN junctions are in opposite directions.

Embodiment 2

[0056] A method for preparing a silicon solar cell with integrated bypass diodes, comprising the following process steps:

[0057] First, the substrate adopts P-type single-sided polishing, crystal orientation , resistivity 10Ω·cm±1Ω·cm, thickness 0.16m±0.02mm type silicon wafer; then the product is manufactured according to the following process sequence.

[0058] 1. Silicon wafer oxidation 1:

[0059] Turn on the diffusion furnace, pass dry oxygen at 1900mL / min to 2000mL / min, and raise the temperature to 700°C.

[0060] Put the silicon wafer into the oxidized quartz boat, place the oxidized quartz boat at the mouth of the wet oxygen oxidation furnace, and preheat for 5 minutes to 10 minutes. Then push the oxidized quartz boat into the constant temperature zone, raise the temperature to 1020°C, start timing, first pass dry oxygen for 10 minutes, then pass wet oxygen for 58 minutes, finally turn on dry oxygen, and turn off the diffusion furnace for heating after passing dry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com