Coating fire-resistant mica tape and processing method thereof

A fire-resistant mica and processing method technology, which is applied to mica, conductors, cables, etc., can solve the problems of low fire-resistant strength and tensile toughness of mica tape, increase the processing cost of manufacturers, and high prices of fire-resistant cables. The processing method is simple, the effect of increasing the cable insulation performance and reducing the number of layers of mica tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

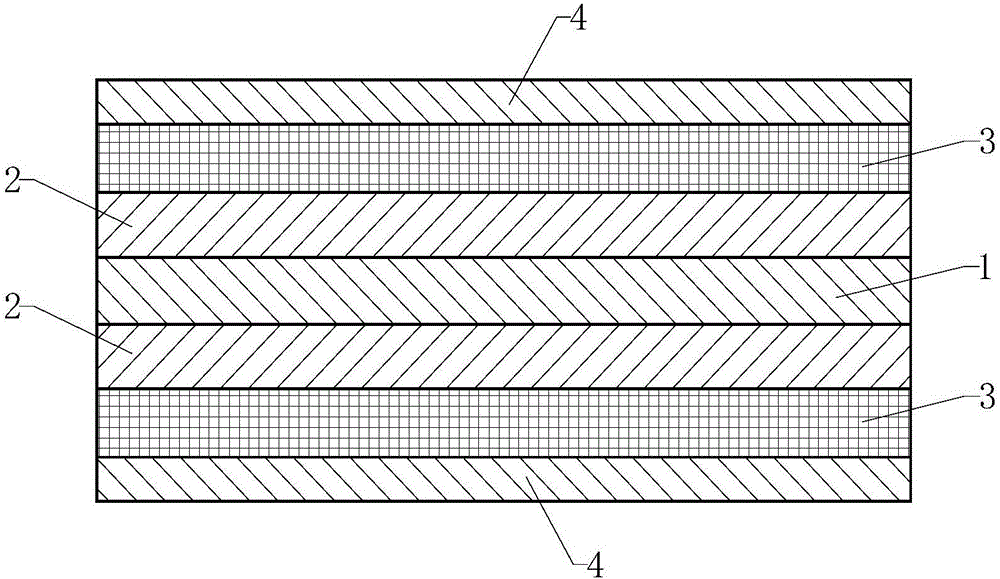

[0022] Such as figure 1 As shown, a coating refractory mica tape includes a mica core layer 1, the upper and lower ends of the mica core layer 1 are provided with a silicone resin adhesive layer 2, and the outside of the silicone resin adhesive layer 2 is provided with a glass The outer surfaces of the fiber cloth 3 and the glass fiber cloth 3 are provided with a high temperature resistant coating 4 .

[0023] The processing method of coating refractory mica tape of the present invention may further comprise the steps:

[0024] 1) Dilute the silicone resin, diluent and magnesium hydroxide to prepare a silicone resin mixed peptizer with a silicone resin content of 18% and a magnesium hydroxide content of 5%; put the mica paper into the silicone resin In the mixed peptizer, the silicone resin mixed peptizer can be evenly immersed in the front and back sides of the mica paper, and then two layers of glass fiber cloth are spread on the surface of the adhesive layer on the front a...

Embodiment 2

[0034] The difference from Example 1 is that the processing method of the coated refractory mica tape comprises the following steps:

[0035] 1) Dilute the silicone resin, diluent and magnesium hydroxide to prepare a silicone resin mixed peptizer with a silicone resin content of 20% and a magnesium hydroxide content of 8%; put the mica paper into the silicone resin In the mixed peptizer, the silicone resin mixed peptizer can be evenly immersed in the front and back sides of the mica paper, and then two layers of glass fiber cloth are spread on the surface of the adhesive layer on the front and back sides of the mica paper respectively. , thus forming a composite mica tape;

[0036] 2) Composite the composite mica tape by a dry laminating machine, and send the composite mica tape into the oven at a speed of 10 / meter per second;

[0037] 3) Stir the silicone resin with organic hydrate and ceramic powder materials to prepare a high-temperature-resistant coating peptizer with a s...

Embodiment 3

[0045] The difference from Example 1 is that the processing method of the coated refractory mica tape comprises the following steps:

[0046]1) Dilute the silicone resin, diluent and magnesium hydroxide to prepare a silicone resin mixed peptizer with a silicone resin content of 22% and a magnesium hydroxide content of 10%; put the mica paper into the silicone resin In the resin mixed peptizer, the silicone resin mixed peptizer can be evenly immersed in the front and back sides of the mica paper, and then two layers of glass fiber cloth are respectively laid on the viscose layer on the front and back sides of the mica paper surface, thereby forming a composite mica tape;

[0047] 2) Composite the composite mica tape by a dry laminating machine, and send the composite mica tape into the oven at a speed of 10 / meter per second;

[0048] 3) Stir the silicone resin with organic hydrate and ceramic powder materials to prepare a high-temperature-resistant coating peptizer with a sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com