Intelligent vacuum grout release machine and intelligent vacuum grout release method

A vacuum and grout draining technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of inconvenient operation, large error, and inability to accurately control the proportion of grout, so as to achieve easy grout draining and improve grouting plumpness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

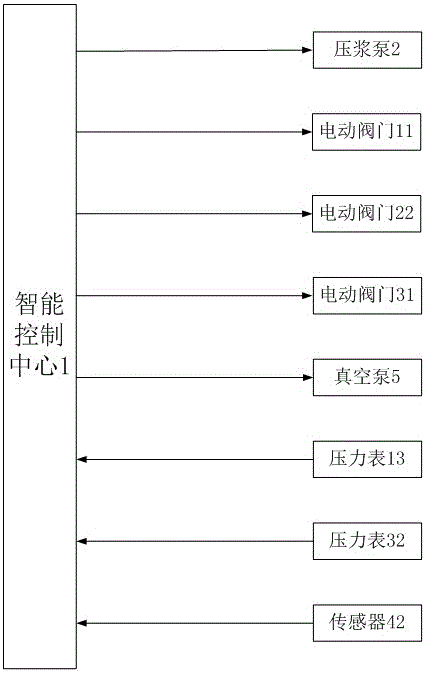

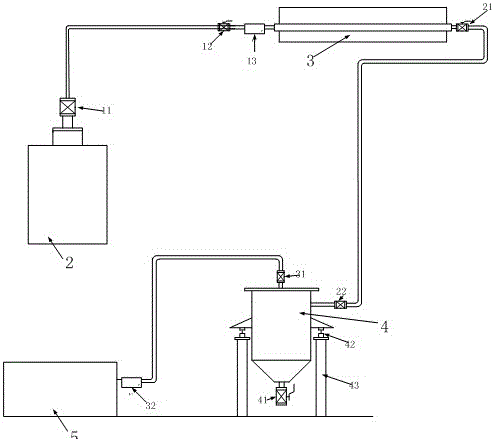

[0010] Refer to attached Figure 1-2 , the present invention provides an intelligent vacuum draining machine, including an intelligent control center 1, a grouting pump 2, a prestressed pipeline 3, a weighing and measuring slurry tank 4, and a vacuum pump 5. The intelligent control center 1 is responsible for controlling the entire intelligent vacuum draining machine. The operation of the pulper can be a single-chip microcomputer, or an existing integrated circuit, or a conventional controller available on the market. The grouting pump 2 is connected with the prestressed pipeline 3 through the first pipeline, and the first The pipeline is equipped with an electric valve 11, a manual valve 12 and a pressure gauge 13. The pressure gauge 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com