A carbon fiber anchor

A carbon fiber board and anchoring technology, which is used in buildings, building reinforcements, building components, etc., can solve the problems of low anchoring efficiency, damaged carbon fiber boards, and inability to adjust, and achieves high anchoring efficiency. The effect of distance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

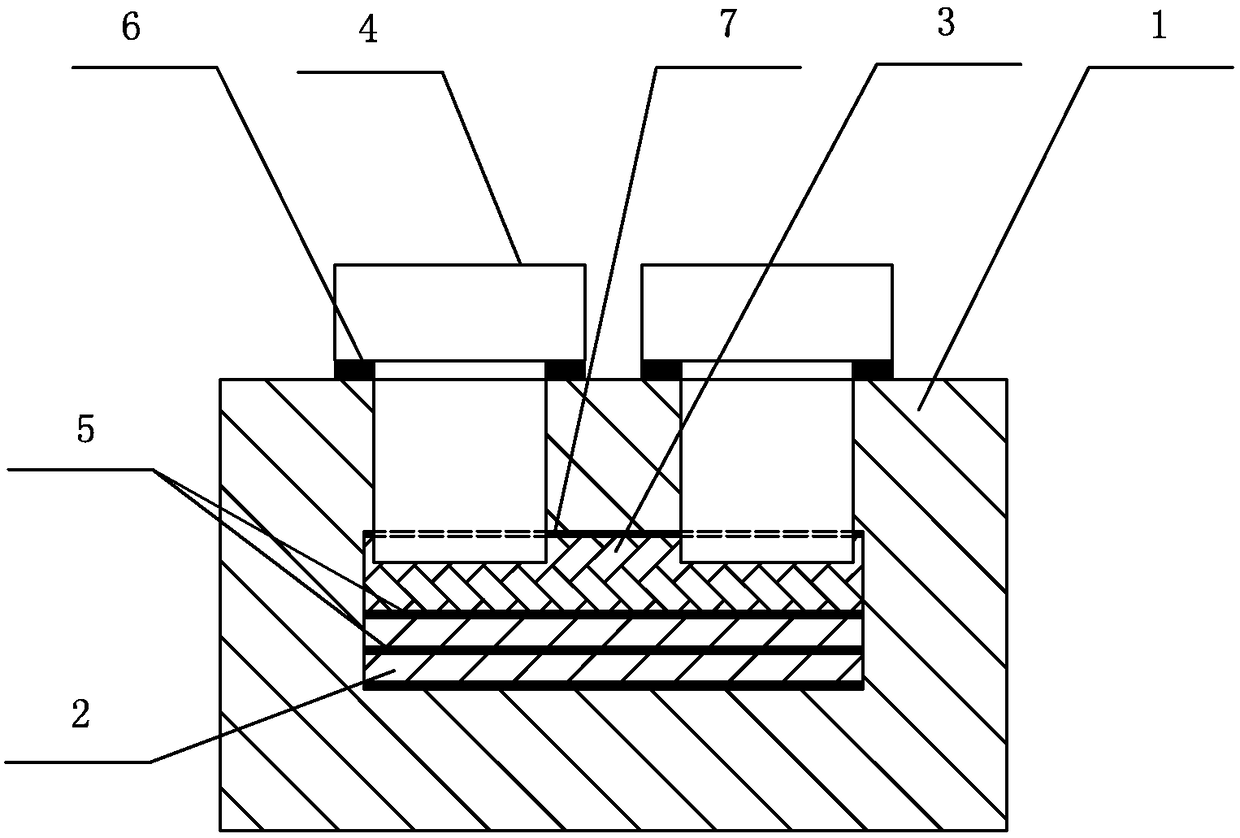

[0018] Embodiment 1: A carbon fiber plate anchor, including an anchor barrel 1 and two carbon fiber plates 2, an anchoring groove 11 is arranged in the anchor barrel 1, and a carbon fiber plate 2 is set in the anchoring groove 11. The carbon fiber plate 2 and the anchor barrel 1 A force transmission backing plate 3 is arranged between the force transmission backing plate 3 and the carbon fiber plate 2, between adjacent carbon fiber plates 2, and between the carbon fiber plate 2 and the anchor tube 1. Colloid 5, the upper part of the anchor cylinder 1 is provided with multiple rows of compression screw hole groups in the axial direction, each row of compression screw hole groups includes a compression screw hole 12, and compression bolts 4 are arranged in the compression screw hole 12, A first sealing device 6 is arranged between the compression bolt 4 and the anchor cylinder 1 , and the compression bolt 4 is tightly pressed on the force transmission backing plate 3 .

Embodiment 2

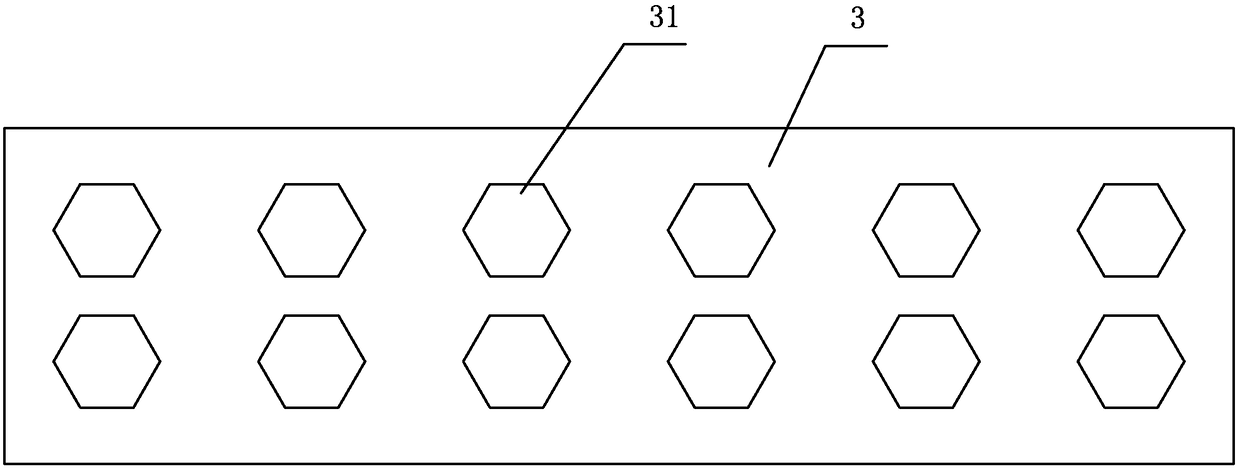

[0019] Embodiment 2: The remaining parts are the same as in Embodiment 1, the difference is that the force transmission backing plate 3 is provided with a compression counterbore 31 corresponding to the compression screw hole 12 one by one, and the compression bolt 4 is embedded in the compression screw hole 12. In the counterbore 31, the anchor barrel 1 and the force transmission backing plate 3 are all made of steel.

Embodiment 3

[0020] Embodiment 3: The rest is the same as Embodiment 1, the difference is that each row of compression screw hole groups includes two compression screw holes 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com