A kind of floor leather based on leather fiber regenerated leather and preparation method thereof

A technology of dermal fiber and regenerated leather, applied in the field of floor leather material and floor leather base manufacturing, can solve the problem of affecting the interface strength and peeling resistance between functional layers, affecting the performance uniformity and service life of floor leather, and being unable to be used as floor leather. Substrate and other issues, to achieve excellent leather feel, excellent dimensional stability, avoid deformation and mildew effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

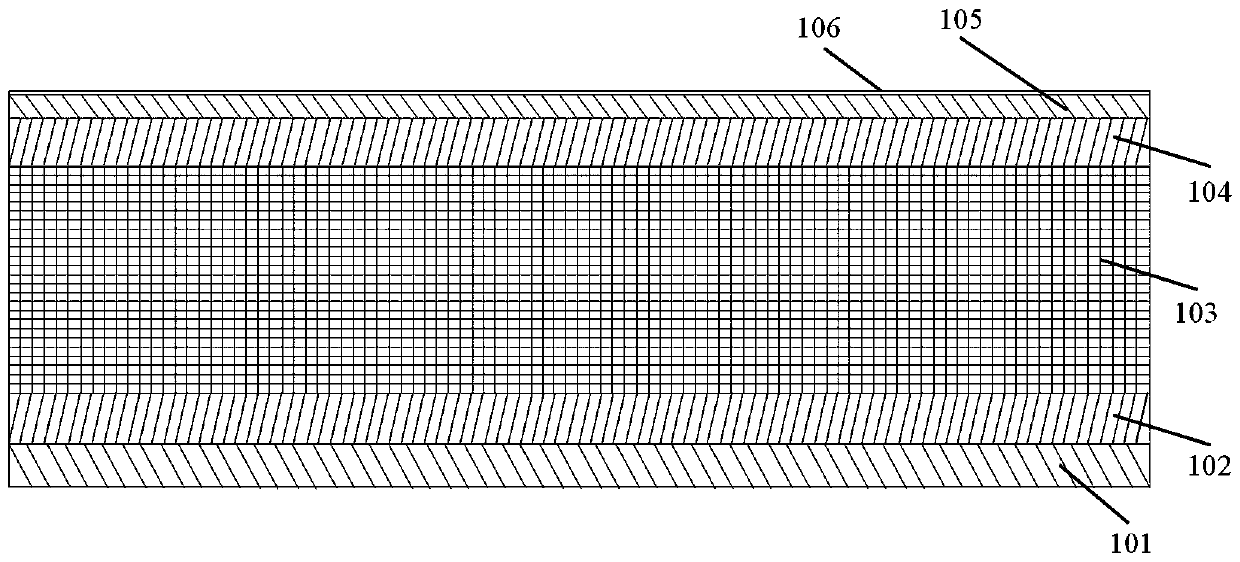

Image

Examples

preparation example Construction

[0044] The preparation method of the genuine leather fiber regenerated leather comprises measuring the above-mentioned raw material fibers in proportion, sending them into an opener for mixing and opening, combing the above-mentioned mixed fiber raw materials into nets or air-laid nets, and then cross-lapping each The fiber mesh layer is laid up, and the cross-laid fiber mesh enters the stabbing area, and the front and back sides of the fiber mesh are needle-fixed; the stabbed fiber mesh is dried and then cut and heat-treated. The heat treatment is divided into two steps. The shaped regenerated leather obtained by stabbing is first kept at 100-120°C for 2-3 minutes, and then at 30-60°C for 30-60 minutes, so that the moisture content of the regenerated leather is 12 to 20%, and finally carry out waterproof treatment on the regenerated leather after heat treatment, and spray waterproof paint on its exposed section to form a waterproof layer and cover the exposed section.

[0045...

Embodiment 1

[0060] A kind of leather fiber regenerated leather for floor leather base layer 103, which is composed of leather fibers, inorganic fibers and viscose fibers with a skin-core structure, the leather fibers are from cowhide, the mass percentage is 70%, and the mass percentage of inorganic fibers is 10 %, the mass percentage of viscose fiber is 20%. The thickness of the regenerated leather is about 2.0mm, the transverse and longitudinal tear strengths are both above 34N, and the transverse and longitudinal tensile strengths are both above 6MPa.

[0061] The manufacturing method of this regenerated leather:

[0062] (1) Impurities removal and classification: First, screen, classify and remove impurities from various leather corners, and select cow leather scraps with higher strength;

[0063] (2) Cutting into pieces: cut the leftover material obtained in (1) into 40×40mm blocks with a pulverizer;

[0064] (3) Puffing and softening: Soak the leather corners obtained in (2) in an ...

Embodiment 2-7

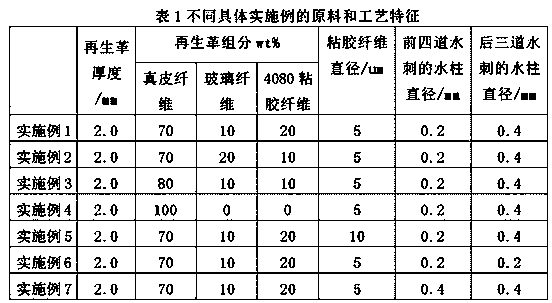

[0073] In order to better compare the effects of different raw materials and processes on regenerated leather products, the following test groups were designed with Example 1 as the control group, as shown in Table 1, and the corresponding test results are shown in Table 2-Table 4.

[0074]

[0075] Wherein embodiment 1-4: the component of regenerated leather is different; Embodiment 1 and embodiment 5: the diameter of the 4080 viscose fiber of blending is different; Embodiment 1, embodiment 6 and embodiment 7: the diameter of spunlace water column different.

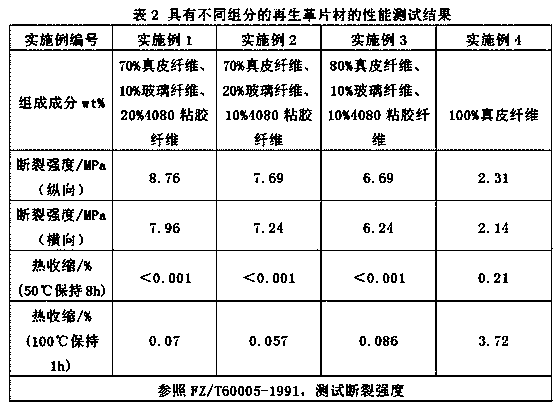

[0076]

[0077]

[0078]

[0079] As can be seen from Table 2: Embodiment 4 is a single-component kraft fiber regenerated leather, which has poor dimensional stability and low strength. Compared with it, Embodiment 1, 2 and 3 have added different proportions of glass fiber and viscose fiber 4080 , the dimensional stability and tensile breaking strength (transverse and longitudinal) of the resulting regenerat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com