Method for preparing nanocrystalline diamond film by using helicon wave plasma technology

A nanocrystalline diamond and plasma technology, which is applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of easy pollution, filament performance attenuation, and low deposition rate of hot filament CVD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

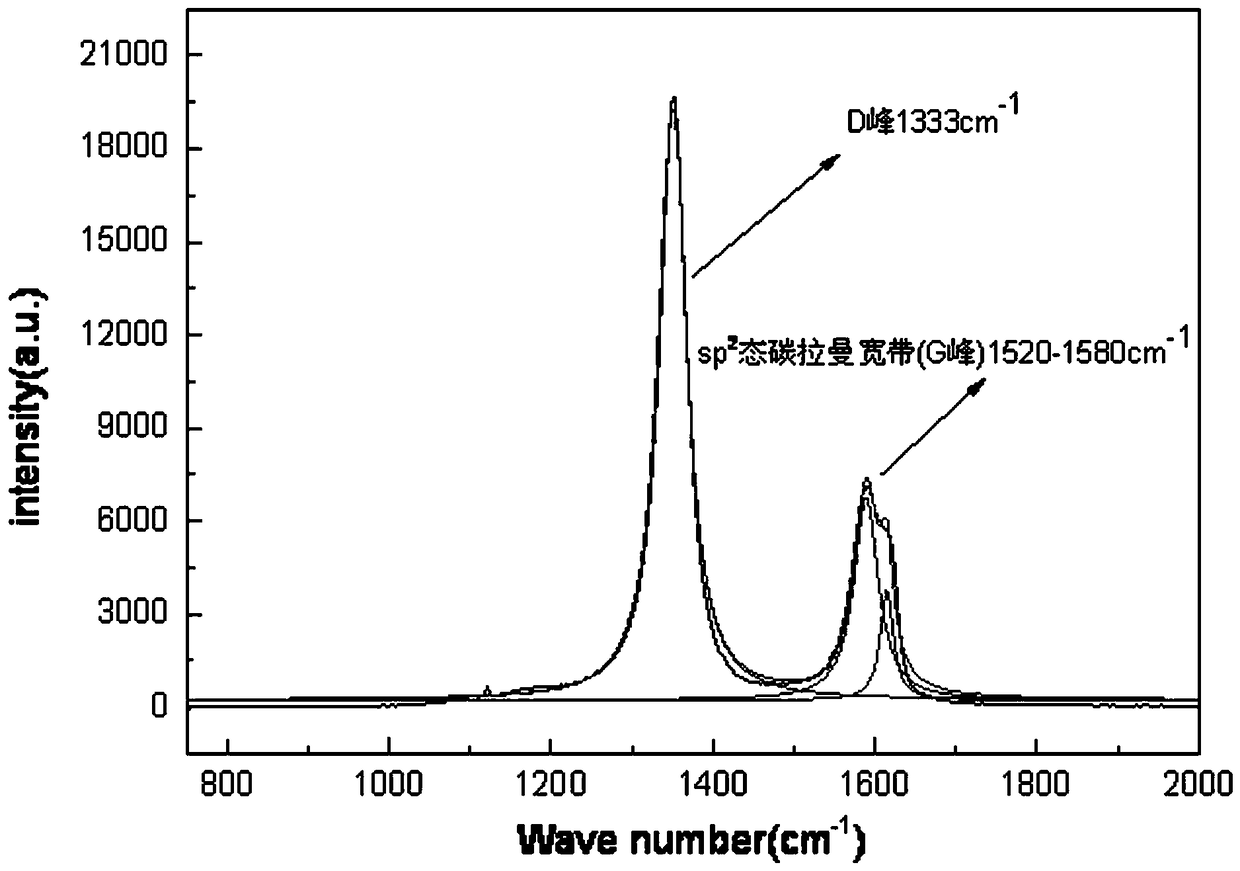

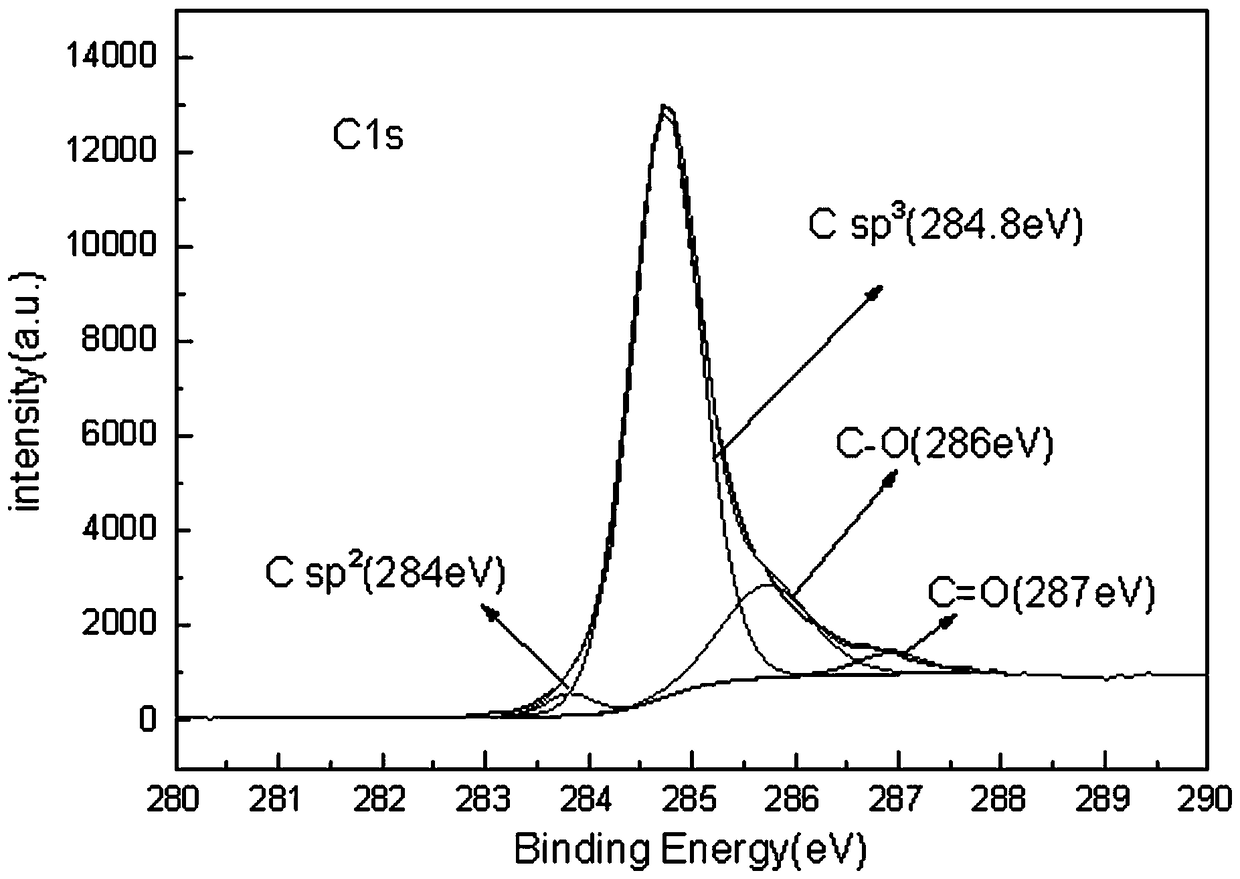

[0025] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0026] The helicon wave plasma technique adopted in the present invention prepares the method for nanocrystalline diamond film, comprises the steps:

[0027] (1) Use single crystal Si with a crystal orientation of as the substrate, and use industrial standard wet cleaning to remove the natural oxide layer and various sticky dirt on the Si surface. Put the cleaned Si substrate on the substrate table and fix it, then pump the discharge chamber to the background vacuum. After being evacuated to the background vacuum, the Ar gas and H 2 The gas is passed into the discharge chamber, and in the axial magnetic field environment, Ar and H are reali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com