Organic salt drilling fluid applicable to extended-reach wells

An extended-reach well, organic salt technology, applied in the field of organic salt drilling fluid, can solve the problems of poor rheology, poor sealing performance of organic salt drilling fluid, poor lubricity, etc., to reduce drill pipe friction and inhibit mud shale The effect of hydration, strong lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

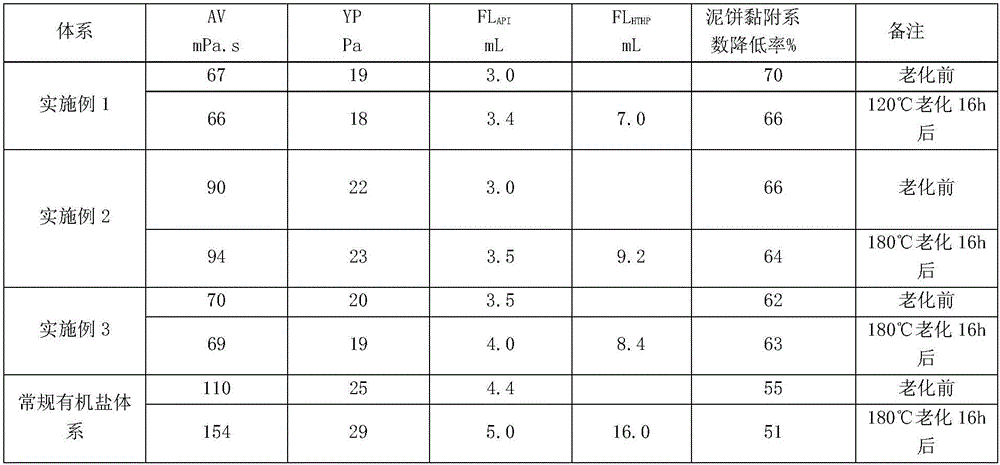

Embodiment 1

[0045] A strong plugging and high temperature resistant organic salt drilling fluid provided by the present invention comprises 1% bentonite, 0.3% sodium carbonate, 0.5% sodium hydroxide, 0.3% xanthan gum, 2% fluid loss control agent, 2% nano plugging agent, 1% sulfonated bitumen, 0.5% lubricant, 40% sodium formate and 100% barite powder.

[0046] Wherein the preparation method of fluid loss reducer is as follows:

[0047] Add 5 parts of acrylamide, 5 parts of N-vinylpyrrolidone and 100 parts of deionized water into a four-necked bottle equipped with a mechanical stirrer. After stirring and dissolving, add an appropriate amount of NaOH to adjust the pH value of the aqueous solution to 9, and then add After 15 parts of N-isopropylacrylamide is completely dissolved, under the protection of nitrogen, slowly add 0.05 parts of ammonium persulfate and 0.05 parts of potassium persulfate, heat and react at 60°C for 6 hours to obtain glue, and then dry it , pulverized to obtain the fl...

Embodiment 2

[0056] A strong plugging and high temperature resistant organic salt drilling fluid provided by the present invention comprises 4% bentonite, 0.5% sodium carbonate, 1% sodium hydroxide, 1% xanthan gum, 8% fluid loss control agent, 5% nano plugging agent, 2% sulfonated bitumen, 1% oxidized bitumen, 1% natural bitumen, 40% sodium formate, 20% potassium formate and 200% barite powder.

[0057] The preparation method of described fluid loss reducer is as follows:

[0058] Add 10 parts of acrylamide, 15 parts of N-vinylpyrrolidone and 100 parts of deionized water into a four-necked bottle equipped with a mechanical stirrer. After stirring and dissolving, add an appropriate amount of NaOH to adjust the pH value of the aqueous solution to 11, and then add After 35 parts of N-isopropylacrylamide is completely dissolved, under the protection of nitrogen, slowly add 0.5 parts of azobisisobutyronitrile and 0.5 parts of azobisisoheptanonitrile, and heat at 80°C for 4 hours to obtain The ...

Embodiment 3

[0067] A kind of strong plugging and anti-high temperature organic salt drilling fluid provided by the invention comprises water and 3% bentonite, 0.3% sodium carbonate, 0.8% sodium hydroxide, 0.5% xanthan gum, 5% fluid loss additive, 4% nano plugging agent, 1% emulsified bitumen, 1% oxidized bitumen, 1% natural bitumen, 40% sodium formate, 20% cesium formate and 150% ilmenite powder .

[0068] The preparation method of described fluid loss reducer is as follows:

[0069] Add 5 parts of acrylamide, 5 parts of N-vinylpyrrolidone, 5 parts of 2-acrylamide-2 methylpropanesulfonic acid and 100 parts of deionized water into a four-necked bottle equipped with a mechanical stirrer, and stir to dissolve, Add an appropriate amount of NaOH to adjust the pH value of the aqueous solution to 10, then add 30 parts of N-isopropylacrylamide, after it is completely dissolved, slowly add 0.05 parts of ammonium persulfate and 0.5 parts of azobisiso Butylamidine dihydrochloride was heated and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com