Electrochemical energy storage device

An energy storage device and electrochemical technology, which is applied in the field of electrochemistry, can solve the problems such as the difficulty of inserting the battery into the shell, and achieve the effects of improving ion conduction capacity, improving long-term cycle performance, and improving liquid swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

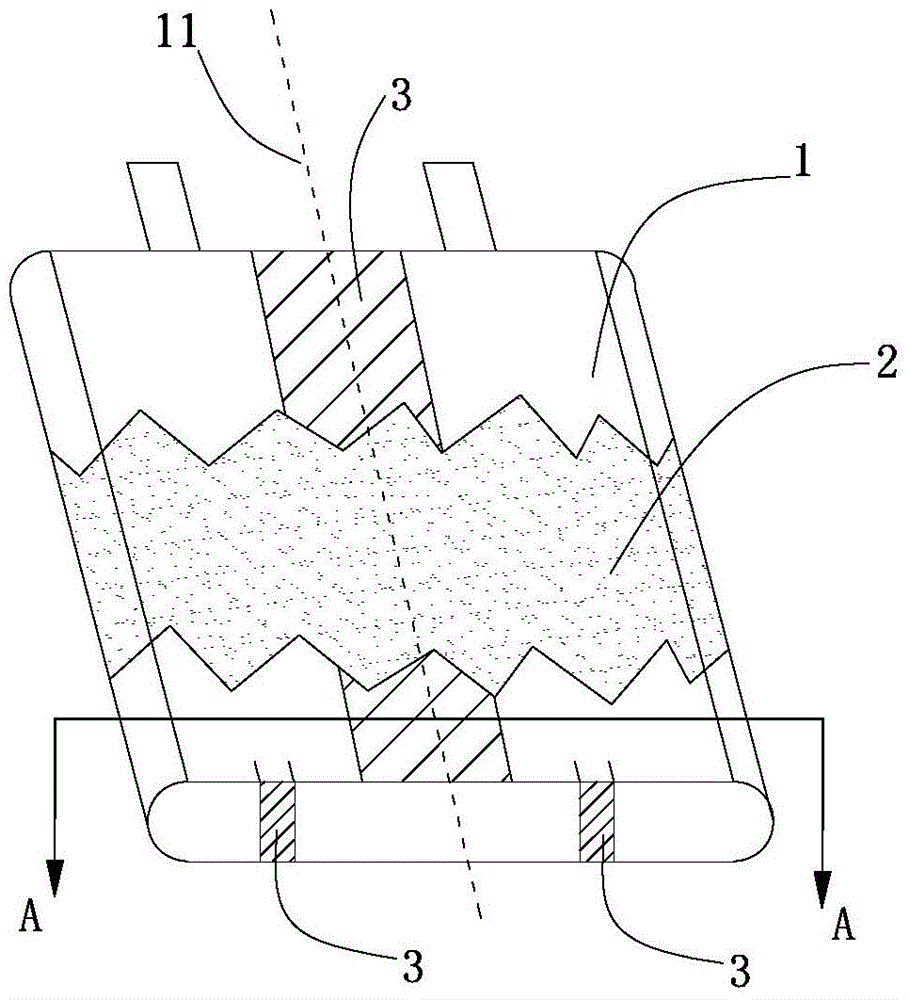

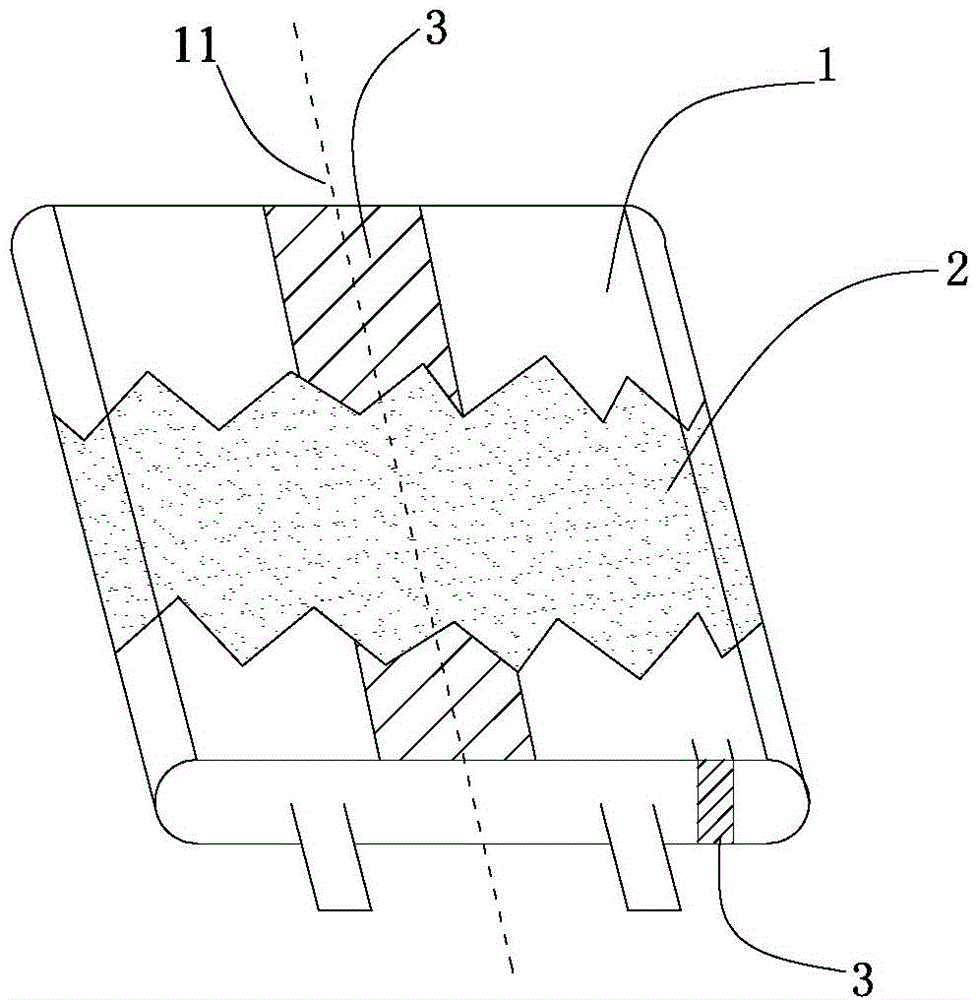

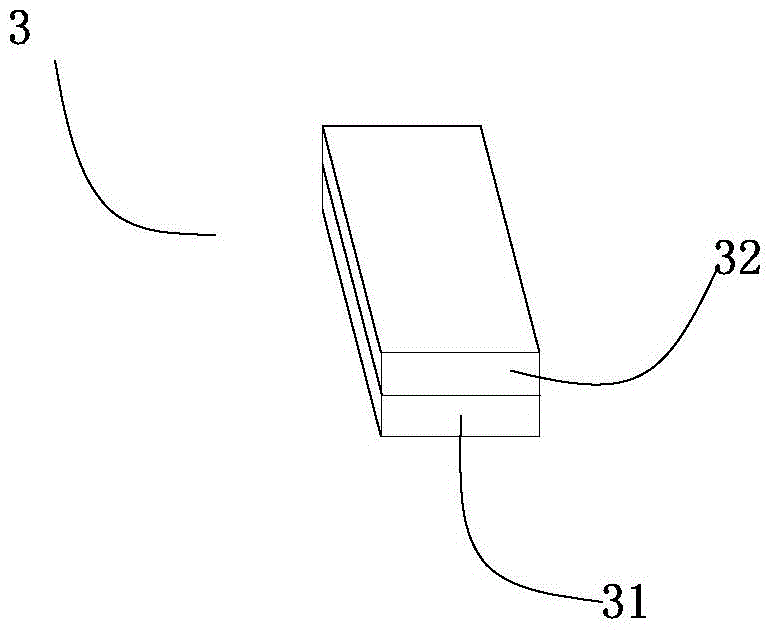

Image

Examples

Embodiment 1

[0050] 1. Preparation of positive electrode sheet

[0051] LiCoO 2 , conductive carbon, and polyvinylidene fluoride are dispersed in N-methylpyrrolidone at a weight ratio of 96:1:3 to make a positive electrode slurry, and then coated and compacted to make a positive electrode sheet with a thickness of 100 μm.

[0052] 2. Preparation of negative electrode sheet

[0053] Disperse graphite, conductive carbon, sodium carboxymethyl cellulose, and styrene-butadiene rubber in deionized water at a weight ratio of 97:1:1:1 to make negative electrode slurry, and then coat and compact to make a negative electrode with a thickness of 90 μm piece.

[0054] 3. Electrolyte Preparation

[0055] Prepare EC, PC, DEC, and EMC in a weight ratio of 20:20:50:10 to make a non-aqueous organic solvent, add 1mol / L LiPF 6 As a lithium salt, the preparation of the electrolyte is completed.

[0056] 4. Cell preparation

[0057] The prepared positive electrode sheet, PP separator, and negative electr...

Embodiment 2

[0065] Lithium-ion secondary batteries were prepared according to the method of Example 1, except for the following differences:

[0066] 5. Preparation of Adhesives

[0067] The protective layer is PVDF with a thickness of 20 μm.

Embodiment 3

[0069] Lithium-ion secondary batteries were prepared according to the method of Example 1, except for the following differences:

[0070] 5. Preparation of Adhesives

[0071] The protective layer is FPP with a thickness of 3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com