Silicon carbon composite material, fabrication method thereof, anode material and battery

A silicon-carbon composite material and silicon material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult preparation process and poor interface contact, and achieve the effects of easy process control, improved utilization rate, and large production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing a silicon-carbon composite material, comprising the steps of:

[0040] S1. Disperse the metal organic compound in the first dispersion medium, add silicon material and mix evenly, and then spray dry to obtain the first precursor;

[0041] S2. Calcining the first precursor at 350-1000° C. in a gas atmosphere to obtain nanoparticles;

[0042] S3, uniformly mixing the nanoparticles and the binder, gradually adding carbon materials, and ultrasonically dispersing to obtain the second precursor;

[0043] S4. Sintering the second precursor at 300-900° C. to obtain a silicon-carbon composite material.

[0044] In S1, metal-organic compounds refer to compounds formed by direct bonding of carbon atoms and metal atoms, and the bonding forms can be covalent bonds, ionic bonds, coordination bonds, etc. The metal organic compound is the metal source of the metal compound in the nanoparticle, and the metal organic compound is selected according to the metal co...

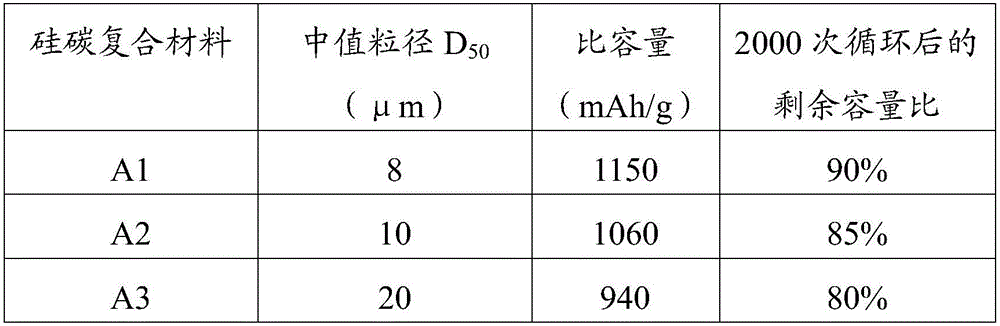

Embodiment 1

[0065] A metal organic compound (trimethylaluminum, 8.5 g) was dispersed in hexane, then a silicon material (silicon powder, 10 nm, 200 g) was added, and stirred for 1 h to obtain a slurry. Then the slurry was input into a spray dryer, and dried at 100° C. to obtain the first precursor.

[0066] The first precursor is fed into a continuous reaction furnace and calcined at 500° C. for 9.5 hours under an oxygen atmosphere; nanoparticles are obtained.

[0067] Disperse the nanoparticles and the binder polyvinylidene fluoride PVDF in N-methylpyrrolidone NMP, then disperse the carbon material (carbon nanotubes, 10 g) in hexane, and stir for 1 h. Then dry at 110° C. for 3 h to obtain the second precursor.

[0068] The second precursor was sent into a continuous reaction furnace for sintering at 750 °C for 11.5 h.

[0069] The obtained silicon-carbon composite material is denoted as A1.

Embodiment 2

[0071] The second embodiment is basically the same as the first embodiment, except that the silicon material (SiO 2 , 200 nanometers, 150g), metal-organic compound (dimethylmagnesocene, 5.6g), carbon material (graphene, 8g); other parts are the same as in Example 1.

[0072] The obtained silicon-carbon composite material is denoted as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com