An electric pole rotary cutting machine

A technology of rotary cutting machine and electric pole, which is used in building maintenance, building types, buildings, etc., can solve problems such as road damage, uneven fractures, and difficulty in pulling out, and achieve automation, improve work efficiency, and neat fractures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

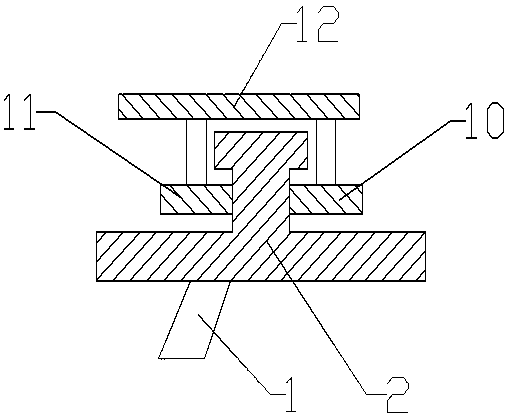

[0019] Accompanying drawing is the specific embodiment of the present invention. Such as figure 1 , figure 2 , image 3 As shown, this kind of electric pole rotary cutting machine includes two sections of arc-shaped slide rails 2, one end of these two sections of arc-shaped slide rails 2 is hinged together, and the other end is respectively provided with a handle 3, and the two handles 3 are respectively opened. There are fixing holes, and the fixing holes are equipped with fasteners 4. Through the fasteners 4, the two arc-shaped slide rails 2 can form a circle. The inner diameter of this circle is larger than the maximum diameter of the pole. , so the fastener 4 is preferably used with bolts and butterfly nuts. The cross section of the arc slide rail 2 is I-shaped, and the bottom is preferably wider than the top; Bracket 1, the three brackets 1 are evenly arranged; three guide grooves 5 are welded on the lower surface of the arc-shaped slide rail 2, and the three guide gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com