A kind of coating for tinplate and its production process and application

A production process and technology of tinplate, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of low solvent resistance and high temperature resistance of acrylic acid, limit the use range of tinplate coatings, and reduce the quality of tinplate printing patterns, etc., to achieve strong adhesion performance, enhance the use value, and improve the effect of printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

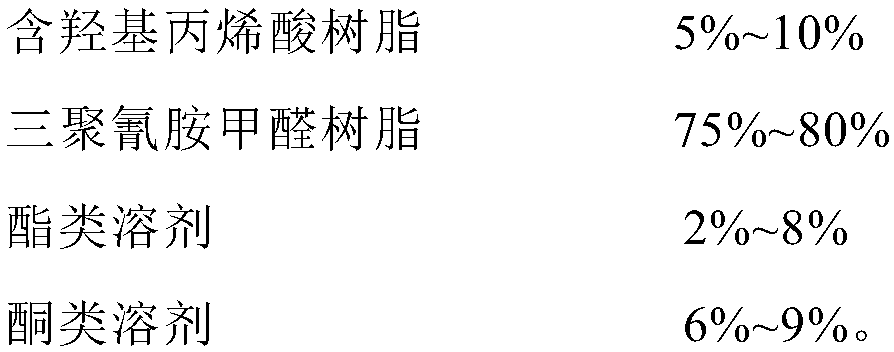

[0045] A coating for tinplate, which comprises the following raw materials by weight:

[0046] Hydroxy-containing acrylic resin 10kg

[0047] Melamine formaldehyde resin 77kg

[0048] Ester solvent 5kg

[0049] Ketone solvent 8kg

[0050] Wherein, the ester solvent of this implementation is ethyl acetate solvent, and the ketone solvent is acetone solvent.

[0051] The production technology of above-mentioned coating for tinplate, it comprises the following steps:

[0052] Step 1, weighing: Weigh 10kg of hydroxyl-containing acrylic acid and 77kg of melamine formaldehyde resin and add them to the reaction kettle for mixing;

[0053] Step 2, batching: Add 5kg of ethyl acetate solvent and 8kg of acetone solvent into the reaction kettle described in step 1, and then stir at 30°C for 40min to prepare the coating for tinplate;

[0054] The finished coating prepared in this embodiment is properly stored in an environment with humidity controlled at 40%.

[0055] A coating for ti...

Embodiment 2

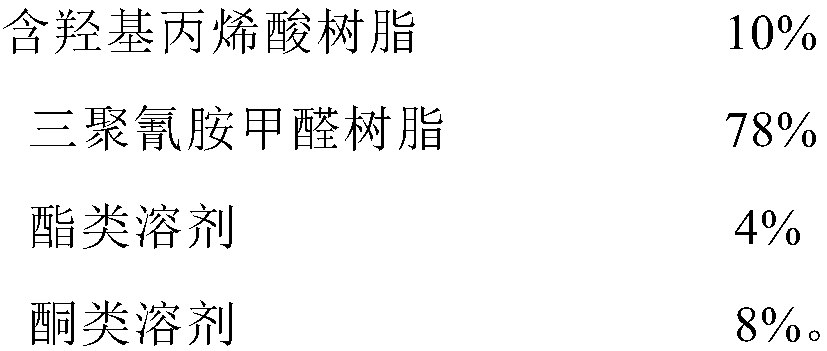

[0059] A coating for tinplate, which comprises the following raw materials by weight:

[0060] Hydroxy-containing acrylic resin 10kg

[0061] Melamine formaldehyde resin 78kg

[0062] Ester solvent 4kg

[0063] Ketone solvent 8kg

[0064] Wherein, the ester solvent in this implementation is butyl acetate solvent, and the ketone solvent is methyl butanone solvent.

[0065] The production technology of above-mentioned coating for tinplate, it comprises the following steps:

[0066] Step 1, weighing: Weigh 10kg of hydroxyl-containing acrylic acid and 78kg of melamine formaldehyde resin and add them to the reaction kettle for mixing;

[0067]Step 2, batching: Add 4kg of ethyl acetate solvent and 8kg of acetone solvent into the reaction kettle described in step 1, and stir at 20°C for 40min to prepare the coating for tinplate;

[0068] The finished coating prepared in this embodiment is properly stored in an environment with humidity controlled at 40%.

[0069] A coating for ...

Embodiment 3

[0073] A coating for tinplate, which comprises the following raw materials by weight:

[0074] Hydroxy-containing acrylic resin 9kg

[0075] Melamine formaldehyde resin 80kg

[0076] Ester solvent 5kg

[0077] Ketone solvent 6kg

[0078] Wherein, the ester solvent of this implementation is ethyl acetate solvent, and the ketone solvent is acetone solvent.

[0079] The production technology of above-mentioned coating for tinplate, it comprises the following steps:

[0080] Step 1, weighing: Weigh 9kg of hydroxyl-containing acrylic acid and 80kg of melamine formaldehyde resin and add them to the reaction kettle for mixing;

[0081] Step 2, batching: Add 5kg of ethyl acetate solvent and 6kg of acetone solvent into the reaction kettle described in step 1, and stir at 30°C for 50min to prepare the coating for tinplate;

[0082] The finished coating prepared in this embodiment is properly stored in an environment with humidity controlled at 30%.

[0083] A coating for tinplate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com