Metal-organic framework nanosheet as well as preparation method and application thereof

A metal-organic framework and metal-organic technology, applied in the direction of nickel organic compounds, cobalt organic compounds, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of restricting large-scale use, restricting large-scale applications, and expensive prices etc. to achieve good film-forming properties, strong alkali resistance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

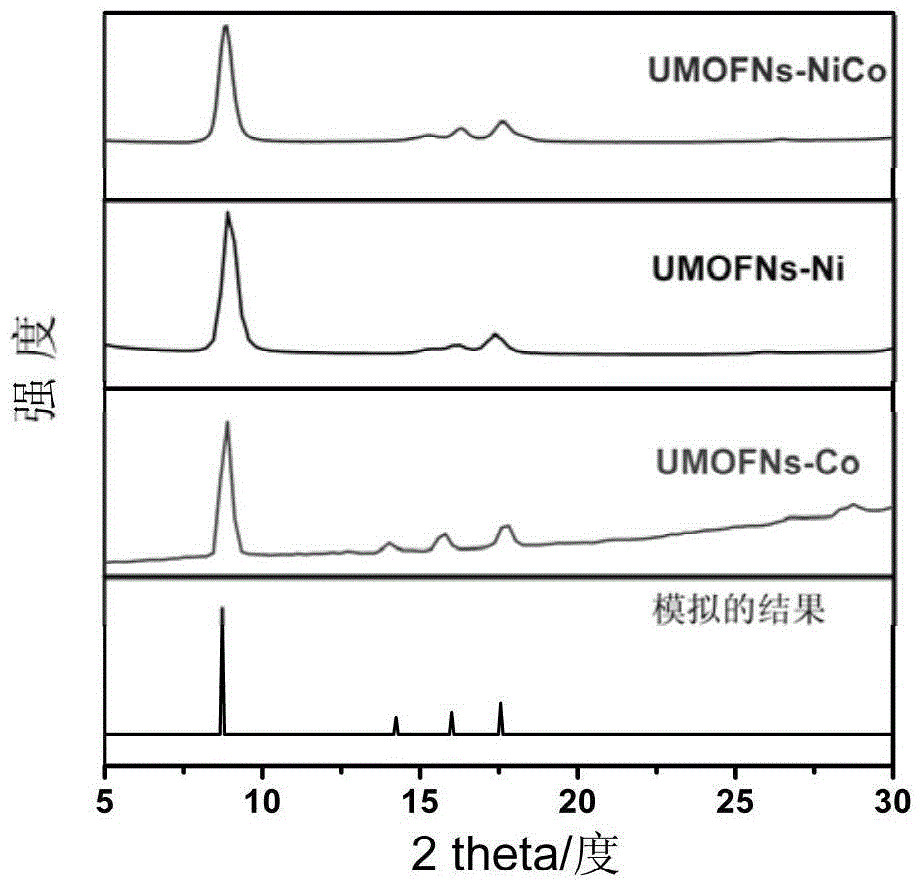

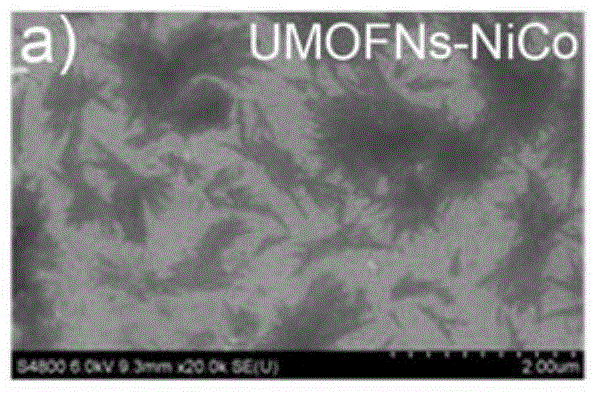

[0077] Dissolve terephthalic acid (2.5mmol) in 100mL of a solvent composed of DMF, water and ethanol (the volume ratio of DMF, water and ethanol is 1:1:1) to obtain a colorless and clear solution, add 0.75mmol (0.18g) CoCl 2 ·6H 2 O and 0.75mmol (0.18g) NiCl 2 ·6H 2 O. At room temperature, 0.1 mL of triethylamine was added dropwise, quickly transferred to ultrasonic conditions for 1 h, and the obtained light blue precipitate was washed 5 times with ethanol, and the color became milky white to obtain 0.72 g of the sample (yield 82%). The obtained powder was heated at 80°C for 30 min under a nitrogen atmosphere to remove guest molecules, and a guest-free metal-organic complex nanosheet was obtained, which was named UMOFNs-NiCo. The X-ray diffraction pattern of the product is shown in figure 1 , XRD shows that the material has four more obvious peaks, corresponding to the (200), (001), (201) and (-201) crystal planes of the crystal respectively; the scanning picture of the p...

Embodiment 2

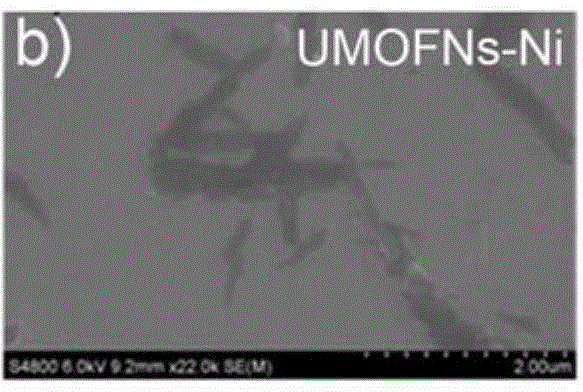

[0084] Dissolve terephthalic acid (2.5mmol) in 100mL of a solvent composed of DMF, water and ethanol (the volume ratio of DMF, water and ethanol is 1:1:1) to obtain a colorless and clear solution, add 1.5mmol (0.36g) NiCl 2 ·6H 2 O. Under normal temperature conditions, 0.1mL triethylamine solution was added dropwise, quickly transferred to ultrasonic conditions for 1h, and the obtained light blue precipitate was washed with ethanol for 3-5 times, and the color became milky white to obtain 0.76g sample (yield 86 %). The obtained powder was heated at 80°C for 30 min under a nitrogen atmosphere to remove the guest molecules, and the guest-free metal-organic complex nanosheets were obtained, named UMOFNs-Ni. The X-ray diffraction pattern of the product is shown in figure 1 , XRD shows that the material has four more obvious peaks, corresponding to the (200), (001), (201) and (-201) crystal planes of the crystal respectively; the scanning picture of the product is shown in Fi...

Embodiment 3

[0091] Dissolve terephthalic acid (2.5 mmol) in 100 mL of a solvent consisting of DMF, water and ethanol (the volume ratio of DMF, water and ethanol is 1:1:1) to obtain a colorless and clear solution, and add 0.75 mmol CoCl 2 ·6H 2 O. Under normal temperature conditions, 5ml of KOH solution with a concentration of 1M was added dropwise, transferred to ultrasonic conditions for 1 h, and the obtained light blue precipitate was washed with ethanol for 3-5 times, and the color became milky white, and 0.68 g of sample (produced rate of 77%). The obtained powder was heated at 80°C for 30 min under a nitrogen atmosphere to remove guest molecules, and a guest-free metal-organic complex nanosheet was obtained, which was named UMOFNs-Co. The X-ray diffraction pattern of the product is shown in figure 1 , XRD shows that the material has four more obvious peaks, corresponding to the (200), (001), (201) and (-201) crystal planes of the crystal respectively; the scanning picture of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overpotential | aaaaa | aaaaa |

| Overpotential | aaaaa | aaaaa |

| Overpotential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com