Safe environment-friendly thermal-insulation material and preparation method thereof

A technology of thermal insulation materials, safety and environmental protection, applied in the field of building materials, can solve the problems of thermal insulation materials occupying a large space, human immune dysfunction, affecting human health, etc., to achieve the effect of light weight, simple construction, and scientific compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

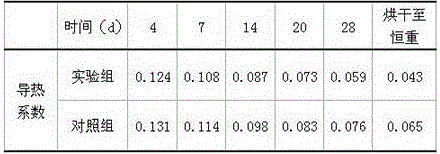

Image

Examples

Embodiment 1

[0027] Example 1 A safe and environmentally friendly thermal insulation material is prepared from the following raw materials, all in parts by weight (300kg / part): 34 parts of bentonite, 10 parts of graphite, 8 parts of silicon carbide, 5 parts of mica powder, carboxymethyl fiber 4 parts of plain sodium, 2 parts of aluminum powder.

[0028] A preparation method of a safe and environmentally friendly thermal insulation material is:

[0029] (1) Grind bentonite, graphite, silicon carbide, mica powder and aluminum powder, pass through a 155-mesh sieve, and mix to obtain a mixed fine powder for later use;

[0030] (2) Put the mixed fine powder obtained in step (1) in a mixer, add 0.45 times the amount of mixed fine powder with water and a catalyst (the catalyst is calcium lignosulfonate with a mass fraction of 1.66%), at 65°C Heat and stir for 15 minutes to make a slurry and set aside;

[0031] (3) Put sodium carboxymethylcellulose in a reaction kettle, add 0.35 times the amount...

Embodiment 2

[0033] Example 2 A safe and environmentally friendly thermal insulation material, prepared from the following raw materials, all in parts by weight (140kg / part): 44 parts of bentonite, 18 parts of graphite, 14 parts of silicon carbide, 9 parts of mica powder, carboxymethyl fiber 8 parts of plain sodium, 4 parts of aluminum powder.

[0034]A preparation method of a safe and environment-friendly thermal insulation material is:

[0035] (1) Grind bentonite, graphite, silicon carbide, mica powder and aluminum powder, pass through a 185-mesh sieve, and mix to obtain a mixed fine powder for later use;

[0036] (2) Put the mixed fine powder obtained in step (1) in a blender, add 0.65 times the amount of mixed fine powder with water and a catalyst (the catalyst is calcium lignosulfonate with a mass fraction of 1.82%), at 95°C Heat and stir for 35 minutes to make a slurry and set aside;

[0037] (3) Put sodium carboxymethylcellulose in a reaction kettle, add 0.55 times the amount of ...

Embodiment 3

[0039] Example 3 A safe and environmentally friendly thermal insulation material is prepared from the following raw materials, all in parts by weight (260kg / part): 37 parts of bentonite, 12 parts of graphite, 10 parts of silicon carbide, 6 parts of mica powder, carboxymethyl fiber 5 parts of plain sodium, 2.5 parts of aluminum powder.

[0040] A preparation method of a safe and environment-friendly thermal insulation material is:

[0041] (1) Grind bentonite, graphite, silicon carbide, mica powder and aluminum powder, pass through a 165-mesh sieve, and mix to obtain a mixed fine powder for later use;

[0042] (2) Put the mixed fine powder obtained in step (1) in a mixer, add 0.5 times the amount of mixed fine powder with water and a catalyst (the catalyst is calcium lignosulfonate with a mass fraction of 1.70%), at 70°C Heat and stir for 20 minutes to make a slurry and set aside;

[0043] (3) Put sodium carboxymethylcellulose in a reaction kettle, add 0.4 times the amount of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com