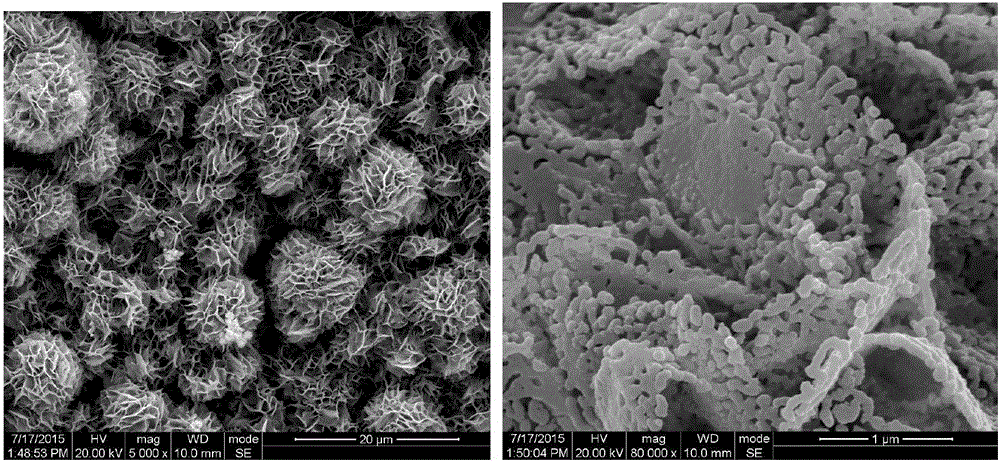

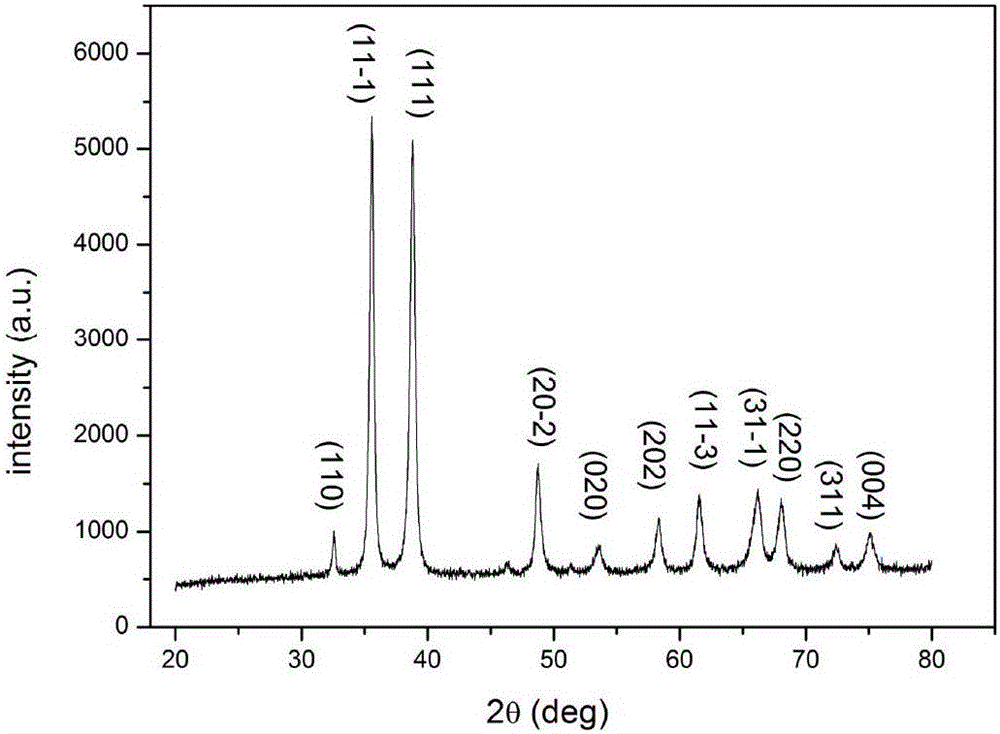

Flower-shaped copper oxide nanostructure material and preparation method thereof

A nanostructure, flower-like structure technology, applied in the field of inorganic material preparation, to achieve the effect of simple production process, strong controllability, and increased diffusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Dissolve 3g of copper acetate in 65ml of deionized water to obtain a dark green clear solution, then add 1g of sodium hydroxide, stir to dissolve and cool to room temperature, then stir and drop in 25ml of ammonia water with a mass concentration of 25% within 5 minutes, and then Stirring was continued at room temperature for 30 minutes to obtain a blue-green solution.

[0020] The above reaction solution was transferred to a polytetrafluoroethylene-lined hydrothermal kettle. Place the ceramic tube vertically at the bottom of the kettle, then seal it, conduct a hydrothermal reaction at 180°C for 24 hours, and cool it to room temperature in air. After the hydrothermal reaction, the ceramic tube was washed three times with deionized water and ethanol, and dried at 80° C. for 1 hour to obtain a black copper oxide nanomaterial precursor attached to the ceramic tube.

[0021] Then bake the ceramic tube with black copper oxide at 600° C. for 2 hours to obtain the copper oxide...

Embodiment 2

[0024] Dissolve 6g of copper acetate in 100ml of deionized water to obtain a dark green clear solution, then add 3g of sodium hydroxide, stir to dissolve and cool to room temperature, then stir and drop 50ml of ammonia water with a mass concentration of 25% in 5 minutes, and then Stirring was continued for 20 minutes at room temperature to give a black solution.

[0025] The above reaction solution was transferred to a polytetrafluoroethylene-lined hydrothermal kettle. Place the ceramic tube vertically at the bottom of the kettle, then seal it, conduct a hydrothermal reaction at 160° C. for 30 hours, and air cool to room temperature. After the hydrothermal reaction, the ceramic tube was washed three times with deionized water and ethanol, and dried at 90° C. for 1 hour to obtain a black copper oxide nanomaterial precursor attached to the ceramic tube.

[0026] Then bake the ceramic tube with black copper oxide at 500° C. for 3 hours to obtain the copper oxide flower-like nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com