Preparation method of ionic-type amphiphilic functionalized graphene

A sexually functional and ionic technology, applied in the field of preparation of functionalized graphene, can solve the problems of reduced electrical conductivity, thermal conductivity and mechanical properties of graphene, reduced structural integrity of graphene nanosheets, etc., and achieves excellent dispersion stability. and amphipathic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

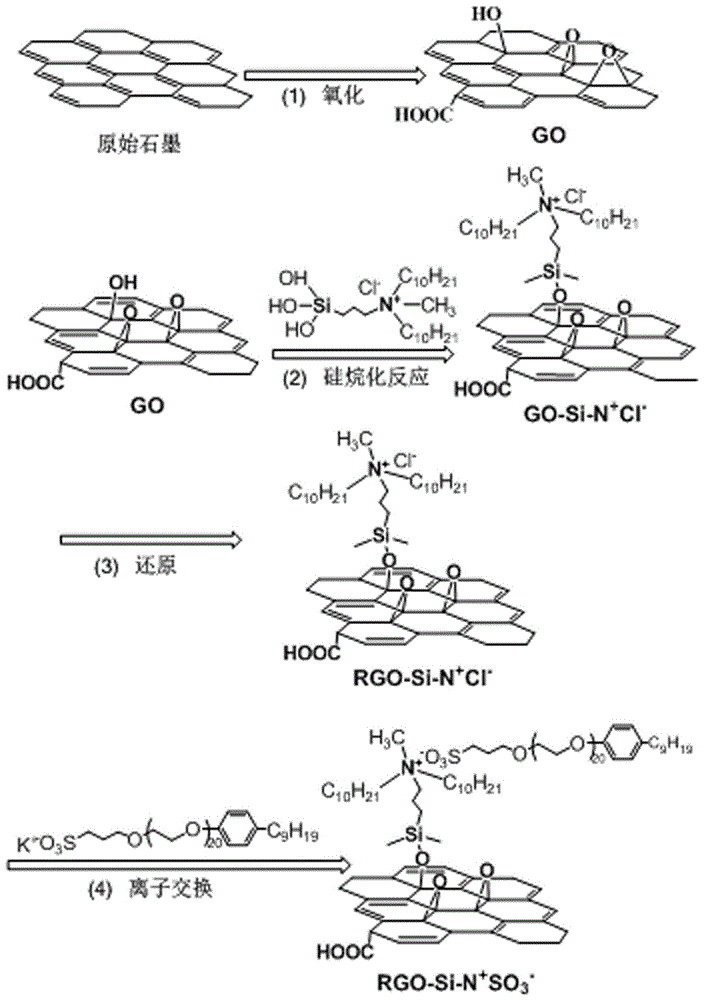

[0017] The preparation method of the ionic amphiphilic functionalized graphene of the present invention comprises the steps of preparation of graphene oxide, silanization treatment, reduction of silylated graphene oxide, ion exchange and the like.

[0018] Wherein, the preparation of described graphene oxide adopts improved Hummers method, uses strong acid concentrated sulfuric acid, potassium permanganate (KMnO 4 ) and strong oxidizing agent - hydrogen peroxide (H 2 o 2 ) Oxidize the expanded graphite, so that the surface of the graphite sheet contains oxygen-containing groups such as hydroxyl, epoxy, and carboxyl due to oxidation.

[0019] Among them, the silanization treatment is to use the highly active ionic structure silane coupling agent and the graphene oxide to form Si-O-C bonds between the hydroxyl groups to obtain silanized graphene oxide.

[0020] Among them, the reduction preparation of silanized graphene is obtained by reducing the silanized graphene oxide with...

Embodiment 1

[0024] The graphene oxide prepared by the improved Hummers method was completely dried at a low temperature of 40°C, then dispersed in deionized water, and ultrasonically dispersed for 2 hours until the graphene oxide was uniformly dispersed. Add 10wt% dilute hydrochloric acid aqueous solution to it to adjust the pH of the solution to about 3, GO and the charged silane coupling agent decitronium chloride carry out a silanization reaction, and then use hydrazine hydrate to reduce the silanized graphene oxide, and finally An ion exchange reaction occurs between the silanized graphene and the anionic surfactant to obtain the final product. Since the pH value of the solution has an effect on the grafting density of the silane coupling agent during the silylation reaction, the product at this pH value is named RGO-Si-N + SO 3 - (pH=3). Specific steps are as follows:

[0025] 1), the preparation of graphene oxide, adopt improved Hummers method to prepare graphene oxide (GO), get...

Embodiment 2

[0027] The graphene oxide prepared by the improved Hummers method was completely dried at a low temperature of 40°C, then dispersed in deionized water, and ultrasonically dispersed for 2 hours until the graphene oxide was uniformly dispersed. Add 10wt% dilute hydrochloric acid and sodium hydroxide aqueous solution to adjust the pH of the solution to about 7. GO is silanized with the charged silane coupling agent dicermonium chloride, and then the silanized graphene oxide is silanized with hydrazine hydrate. Reduction is carried out, and finally an ion exchange reaction occurs between the silanized graphene and the anionic surfactant to obtain the final product. Since the pH value of the solution has an effect on the grafting density of the silane coupling agent during the silylation reaction, the product at this pH value is named RGO-Si-N + SO 3 - (pH=7). Specific steps are as follows:

[0028] 1), the preparation of graphene oxide, adopt improved Hummers method to prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com