Continuous super-light regularly-oriented pure graphene aerogel film and preparation method thereof

A graphene airgel, graphene technology, applied in the direction of graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of unnoticed airgel film performance, unguaranteed graphene airgel film, size limitation Structural design and other issues to achieve the effect of reducing edge defects, enhancing performance, and reducing the internal resistance of electrical and thermal conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

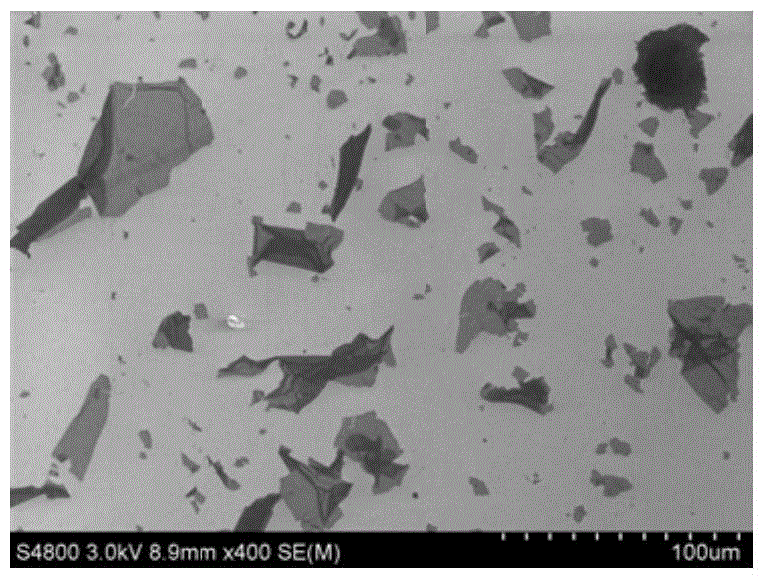

[0032] Example 1: Preparation of Graphene Oxide without Fragmentary Super Large Sheets

[0033] Example 1-1

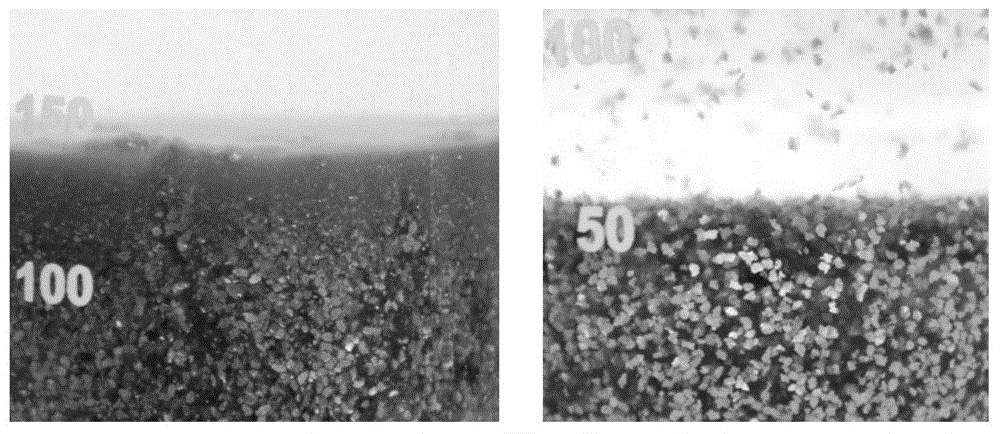

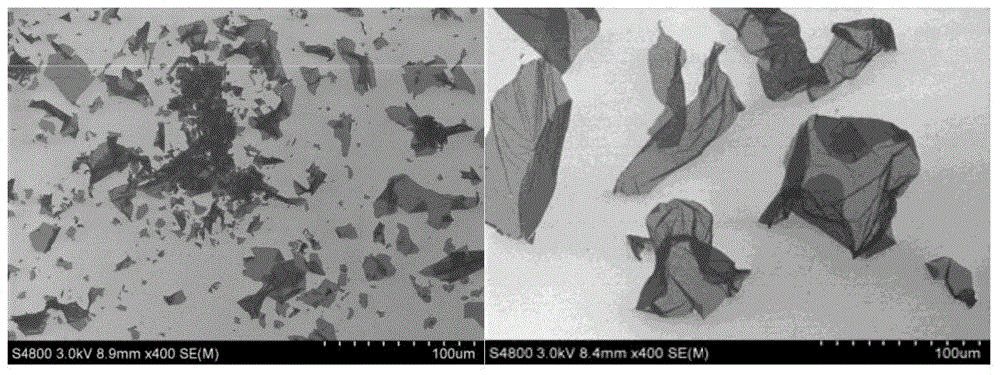

[0034] (1) Slowly add potassium permanganate into the rapidly stirring concentrated sulfuric acid at -10°C. After fully dissolving, add graphite, stir slowly at 60 rpm for 2 hours, then stop stirring. Reaction 6h, obtain the graphite oxide crystal of wide distribution respectively; As figure 1 As shown, there are more fragments in the graphite oxide wafers obtained under the two temperatures, which makes its corresponding graphene oxide also have a lot of fragments ( figure 2 ).

[0035](2) The reaction solution obtained in step 1 is diluted with concentrated sulfuric acid (the dilution factor can be any multiple, and the present embodiment is diluted about 10 times), and the graphite oxide crystals are filtered out with a titanium alloy mesh sieve with a 150um aperture (140 mesh) (Reaction solution recovery), and slowly pour into rapidly stirred ice water relative...

Embodiment 2

[0043] Embodiment 2: Using the non-fragmented super large sheet of graphene oxide prepared in embodiment 1 to prepare a continuous ultra-light and regularly oriented pure graphene airgel film.

[0044] (1) After continuously extruding the graphene oxide aqueous solution with a concentration of 10 mg / mL and an average size of 110 um from a preparation device with an inline outlet at a constant speed (between 10 m / min), stay in liquid nitrogen for 20 seconds, and solidify To form a graphene oxide gel film, freeze the graphene oxide gel film in a refrigerator at -4°C for 5 hours.

[0045] (2) Send the graphene oxide airgel film after the freezing treatment in step 1 into a high-temperature furnace for high-temperature heat treatment. The treatment method is: first raise the temperature to 400°C at 2°C / min in an inert gas atmosphere, keep it warm for 1h, and then In an inert gas atmosphere, heat up to 1300°C at 3°C / min, hold for 2h, then raise the temperature to 3000°C at 4°C / min,...

Embodiment 3

[0049] Embodiment 3: Using the non-fragmented super large sheet of graphene oxide prepared in embodiment 1 to prepare a continuous ultra-light and regularly oriented pure graphene airgel film.

[0050] Continuously extrude an aqueous solution of a certain concentration of ultra-large pieces of non-fragmented graphene oxide (average size of 150um) from a preparation device with a straight-shaped outlet (the device is a cuboid structure with a gradually narrowing straight-shaped die opening in the middle) After exiting, enter the coagulation solution for a period of time, solidify into a graphene oxide gel film, and put it into the refrigerator for slow freezing or quick freezing in liquid nitrogen. The concentration of the ultra-large flake-free graphene oxide solution is between 100 mg / mL. The speed of the continuous uniform extrusion into the coagulation liquid is between 10m / min and the temperature is 30°C. The coagulation liquid is liquid nitrogen. The residence time in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com