A kind of polyaniline modified porous material and its application

A porous material, polyaniline technology, applied in the field of surface modification, to achieve the effects of low cost, good stability, excellent anti-fouling ability and recycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Treatment of the substrate:

[0030] The 2300-mesh stainless steel mesh was ultrasonically cleaned three times with ethanol, acetone, and distilled water, and dried in an oven at 60°C until use.

[0031] (2) Polyaniline modification:

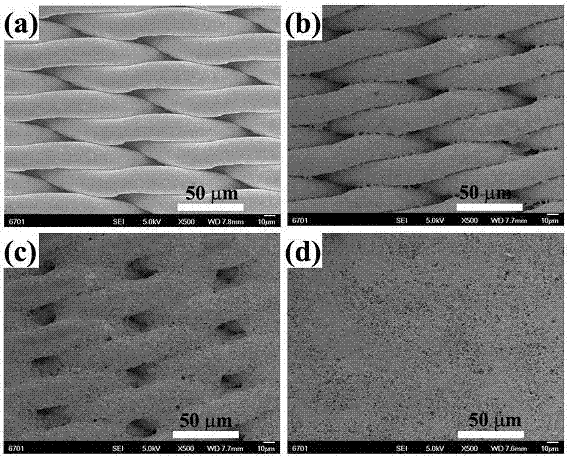

[0032] Measure 70mL of 0.1M aniline-sulfuric acid solution as electrolyte, stainless steel mesh (2.5cm*3cm) as working electrode, platinum sheet electrode (1cm*1cm) as counter electrode, saturated calomel electrode as reference electrode. In a constant temperature water bath (30°C), cyclic voltammetry was used to cycle 5, 10, and 18 times respectively, and the polyaniline was polymerized and grown on the surface of the stainless steel mesh. Finally, it was taken out, washed with an ammonia solution with a pH of 10, and dried. . Scanning electron microscopy of the prepared thin film as figure 1 shown.

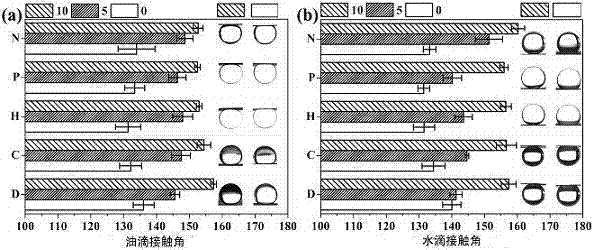

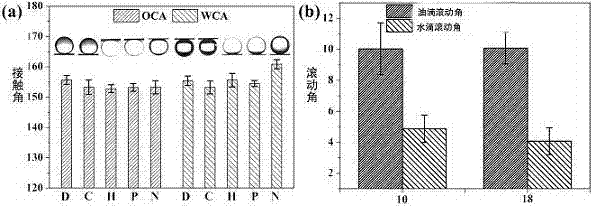

[0033] (3) Separate 0.1 mg / mL Tween80 water-in-n-hexane, petroleum ether and hexadecane under the gravity and 0.1 bar suction pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com