Application of hydrophilic water transport plate in solid polymer electrolyte water electrolysis cell

A technology of solid polymer and water transfer plate, applied in fuel cell components, fuel cell additives, etc., can solve problems affecting battery performance, improve electrolysis performance, facilitate assembly, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

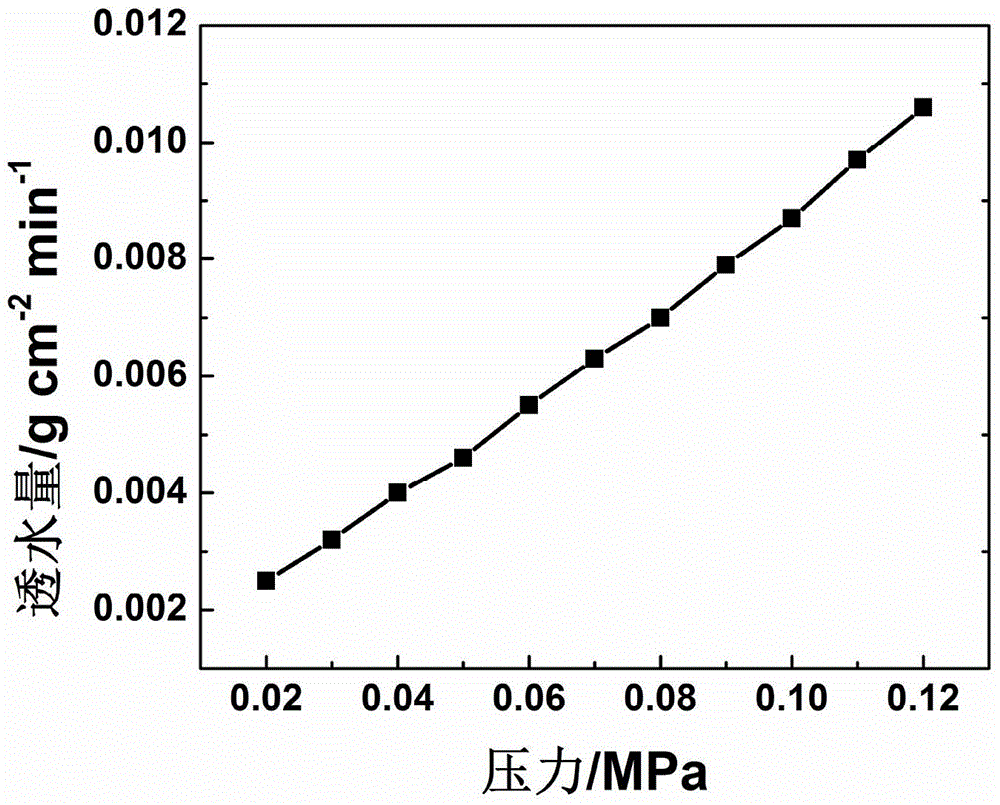

[0024] Example 1: Nano-acetylene black (50nm) was placed in a mixed solution of concentrated nitric acid and concentrated sulfuric acid for stirring treatment, wherein the volume ratio of concentrated sulfuric acid / concentrated nitric acid was 5, the treatment temperature was 40°C, and the treatment time was 10h. Hydrophilicized acetylene black, conductive graphite powder KS150 (35 μm), conductive carbon fiber (diameter 11 μm, aspect ratio 10) and thermosetting phenolic resin are mixed evenly and then hot-pressed with a mold, and the proportion of each component is 5%. :75%:10%:10%, the hot pressing temperature is 200°C (the curing temperature of the thermosetting phenolic resin is 190°C), the pressure is 4MPa, and the hot pressing time is 40min, the hydrophilic acetylene black water transmission plate is obtained, and the thickness of the plate is 1.3mm, parallel strip flow field is distributed on one side surface, and the groove depth of the strip flow field is 0.5mm. Pass 1...

Embodiment 2

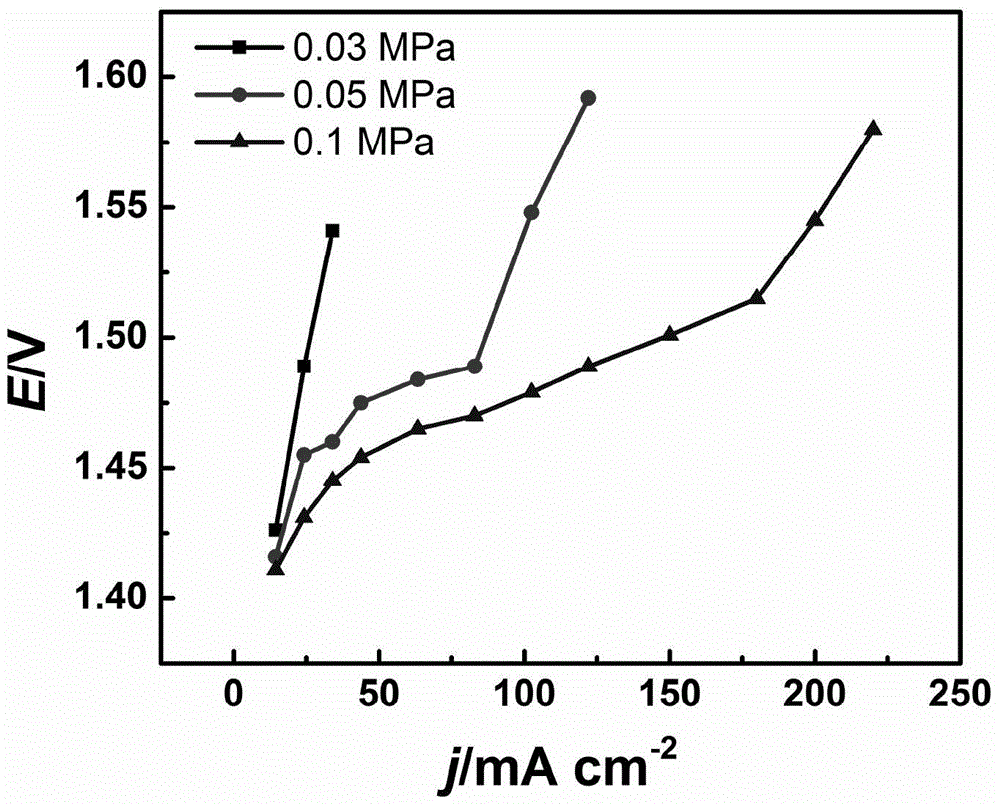

[0025] Example 2: Nano-acetylene black (150nm) was placed in a mixed solution of concentrated nitric acid and concentrated sulfuric acid for stirring treatment, wherein the volume ratio of concentrated sulfuric acid / concentrated nitric acid was 3, the treatment temperature was 25°C, and the treatment time was 24h. Hydrophilicized acetylene black, conductive graphite powder KS75 (50 μm), conductive carbon fiber (diameter 20 μm, aspect ratio 30) and thermoplastic phenolic resin are mixed evenly and then hot-pressed with a mold, and the proportion of each component is 20%. : 60%: 8%: 12%, hot pressing condition is identical with embodiment 1, obtains the hydrophilic acetylene black water transmission plate, and plate thickness is 1.3mm, and one side surface is distributed with parallel strip flow field, strip flow The groove depth of the field is 0.5mm. It was used as the anode current collector, and the flexible graphite was used as the cathode current collector, and assembled w...

Embodiment 3

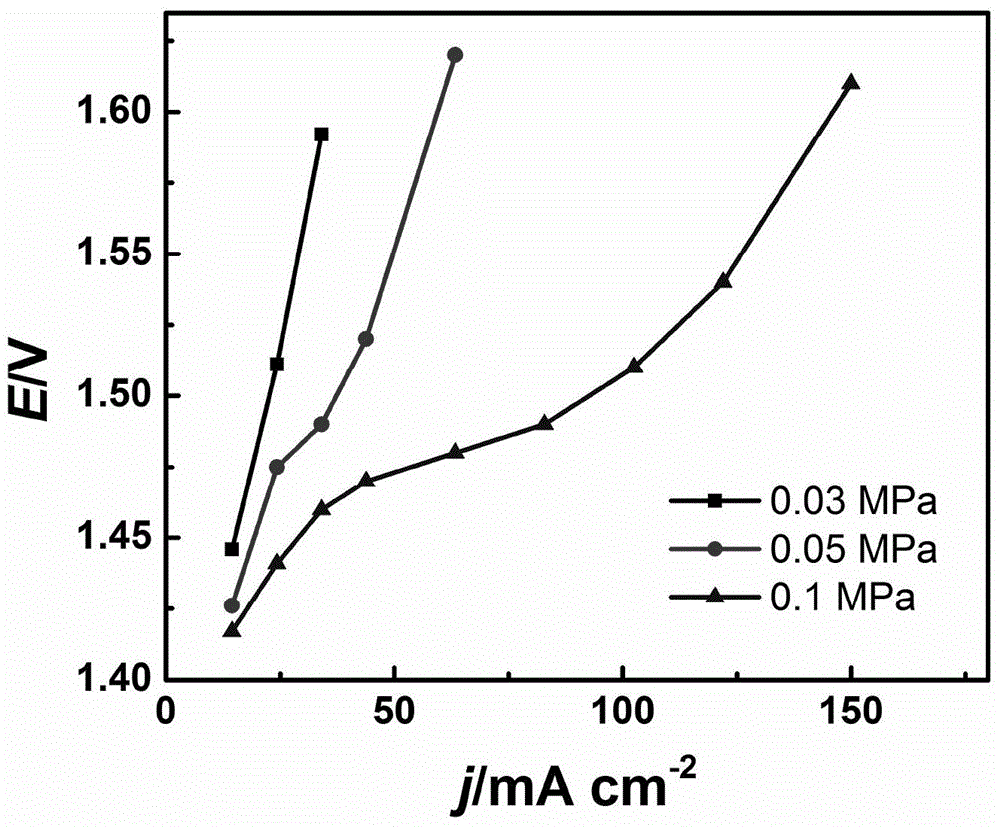

[0026] Example 3: Nano-acetylene black (150nm) was placed in a mixed solution of concentrated nitric acid and concentrated sulfuric acid for stirring treatment, wherein the volume ratio of concentrated sulfuric acid / concentrated nitric acid was 3, the treatment temperature was 25°C, and the treatment time was 24h. Hydrophilicized acetylene black, conductive graphite powder KS75 (50 μm), conductive carbon fiber (diameter 20 μm, aspect ratio 30) and thermoplastic phenolic resin are mixed evenly and then hot-pressed with a mold, and the proportion of each component is 20%. : 60%: 8%: 12%, hot pressing condition is identical with embodiment 1, obtains the hydrophilic acetylene black water transmission plate, and plate thickness is 1.3mm, and one side surface is distributed with parallel strip flow field, strip flow The groove depth of the field is 0.5mm. It was used as the cathode current collector, and the flexible graphite was used as the anode current collector, and assembled w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com