Preparation method of shape-controlled graphene/Co(OH)2 composite materials

A composite material and graphene technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as unevenness and affect the electrochemical performance of composite materials, and achieve low hydrothermal temperature and good charge and discharge. The effect of cycle stability and high charge-discharge cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Prepare 90 mL of graphene oxide solution with a concentration of 0.5 g / mL, and ultrasonically treat it to obtain a uniform and transparent colloidal solution. 2) Weigh tetrahydrate and 1.2 g of cobalt acetate, slowly add the solution in 1) while stirring, control the rotation speed at 200 r / min, and sonicate for 30 min.

[0034] 3) Add 1.5 mL of 0.01 mol / L sodium hydroxide solution and 15 mg of PEI as a surfactant to the solution obtained in step 2), and stir evenly.

[0035] 4) The obtained solution was transferred into a 100 mL polytetrafluoroethylene-lined stainless steel hydrothermal kettle, and kept at a constant temperature of 150° C. for 15 hours.

[0036] 5) After natural cooling, the gel obtained above was washed three times with deionized water, and freeze-dried under vacuum.

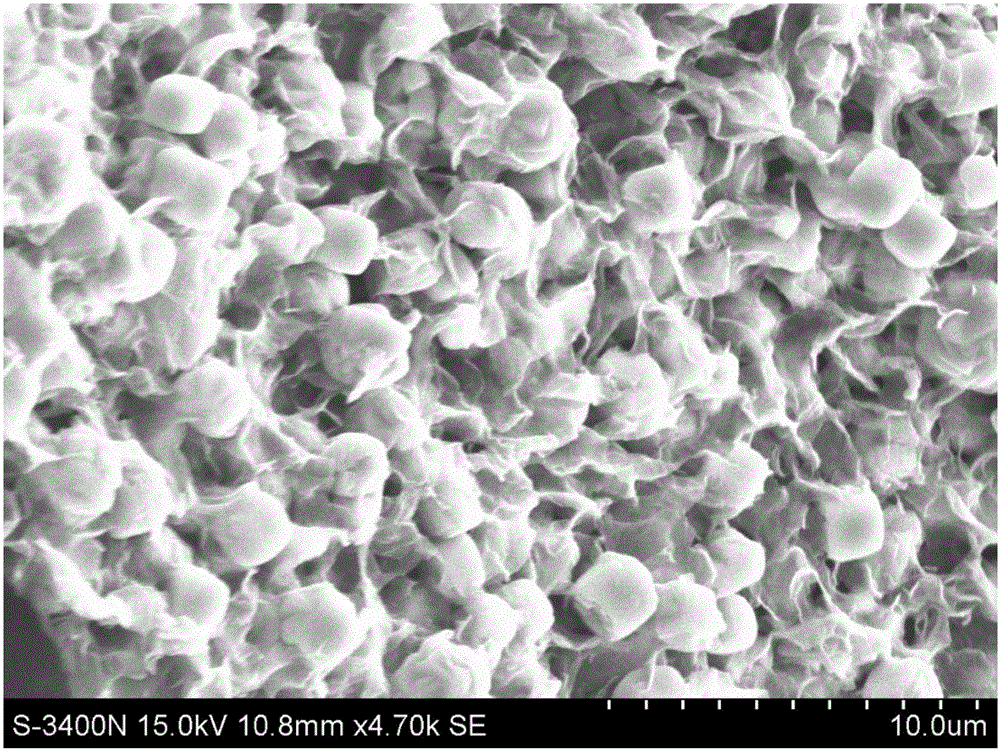

[0037] Adopt Rigaku X-ray diffractometer to determine the crystallinity and the crystal form of the metal oxide in the composite material obtained in the above-mentioned embodiment ...

Embodiment 2

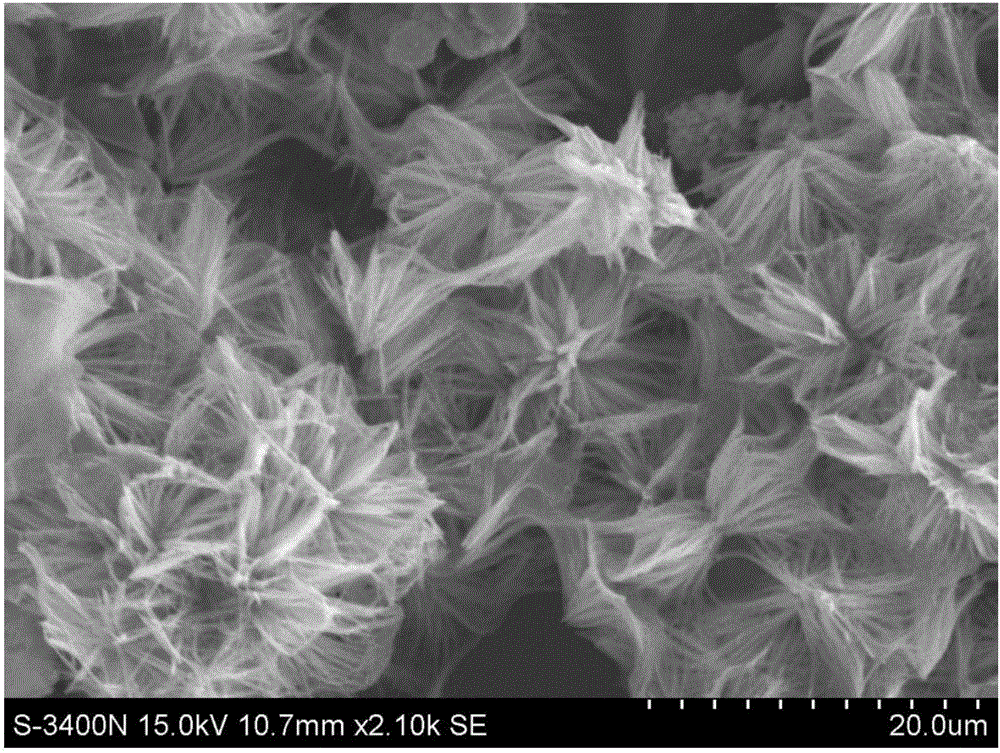

[0041] According to the method of embodiment 1, just change the precipitation agent (0.01M sodium hydroxide solution) in step 3) into 0.2g of urea, change the temperature in step 4) into 170 ℃.

[0042] This graphene / Co(OH) obtained by SEM 2 The shape of the composite material is as figure 2 As shown, it is flower-shaped. The test results of the electrochemical workstation are as follows: Figure 5 As shown in b, the specific capacity is 862F / g. The test results using the blue electric test system are as follows: Figure 6 As shown in b, the capacity retention rate is 93% after 5000 cycles.

Embodiment 3

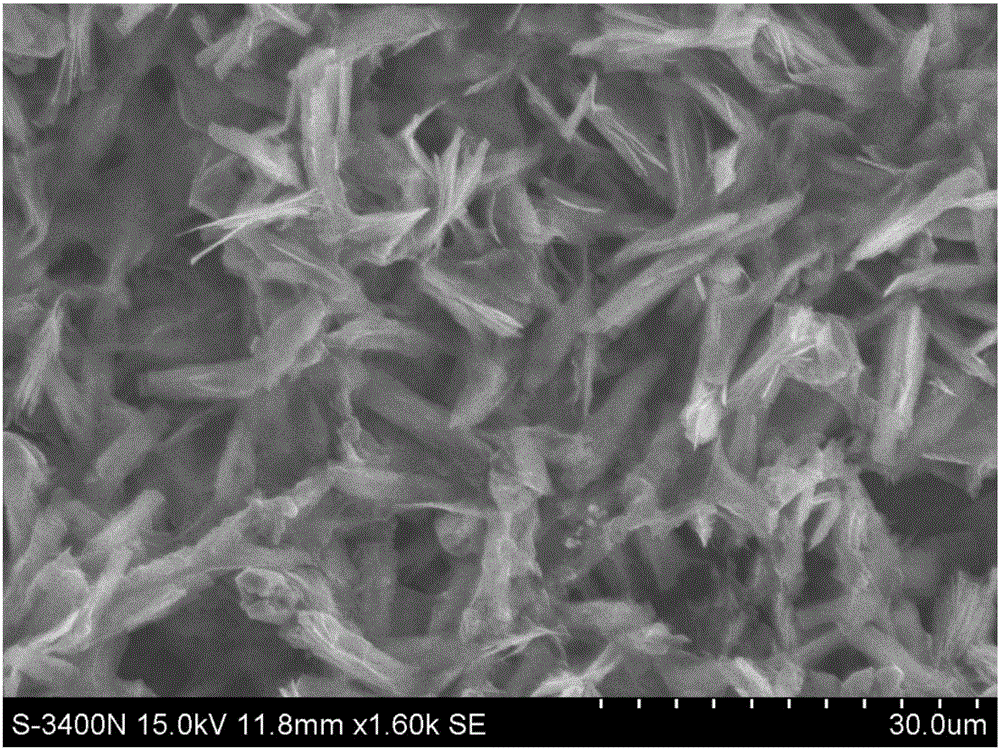

[0044] According to the method of embodiment 1, just change the precipitation agent (0.01M sodium hydroxide solution) in step 3) into 0.15g of urotropine, change the temperature in step 4) into 180 ℃.

[0045] This graphene / Co(OH) obtained by SEM 2 The shape of the composite material is as image 3 As shown, it is rod-shaped. The test results of the electrochemical workstation are as follows: Figure 5 as shown in c. The test results using the blue electric test system are as follows: Figure 6As shown in c, the initial capacity is as high as 983F / g, and after 5000 cycles, the capacity retention rate is 72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com