Blended yarn of aramid fibres and nickel-iron fibres and preparation process for blended yarn

A technology of nickel-iron fiber and aramid fiber is applied in the field of blended yarn preparation, which can solve the problems of inability to meet modern life and industrial production, limited degree of improvement of blended yarn performance, single blended yarn performance and function, etc. Excellent wear resistance, high saturation magnetization and high absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

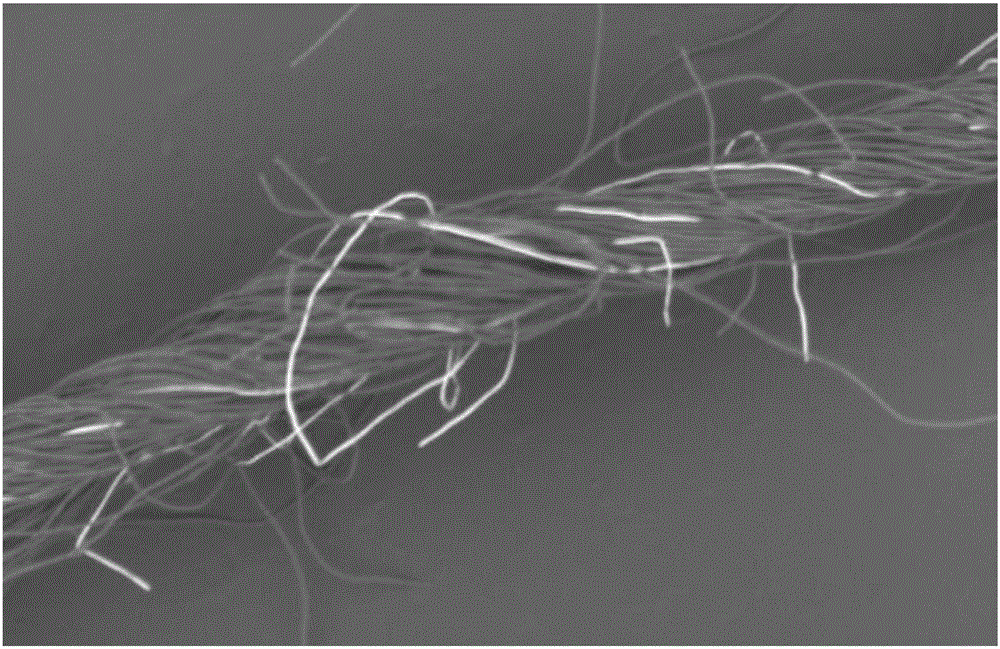

[0024] Please refer to figure 1 As shown, the aramid fiber and nickel-iron fiber blended yarn of the present invention comprises: 75-95 parts by weight of aramid and 5-25 parts by weight of nickel-iron fiber. Preferably, the aramid fiber and nickel-iron fiber blended yarn of the present invention comprises 90 parts by weight of aramid fiber and 10 parts by weight of nickel-iron fiber.

[0025] Preferably, the aramid fiber and ferronickel fiber blended yarn of the present invention comprises: 85 parts by weight of aramid fiber and 15 parts by weight of ferronickel fiber.

[0026] Preferably, the aramid fiber and ferronickel fiber blended yarn of the present invention comprises: 80 parts by weight of aramid fiber and 20 parts by weight of ferronickel fiber.

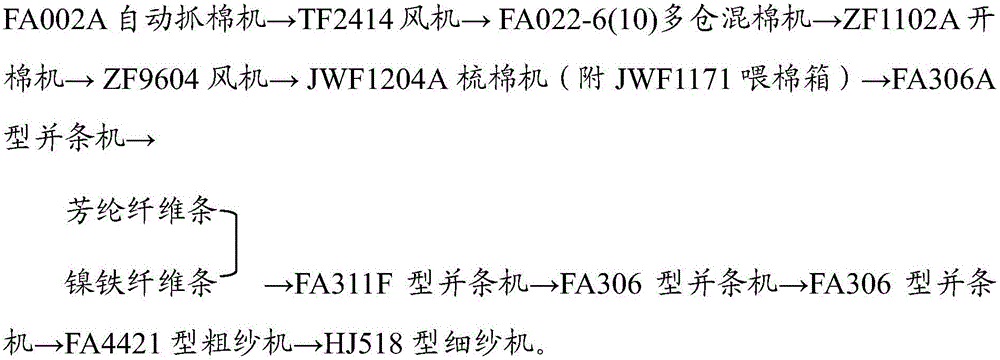

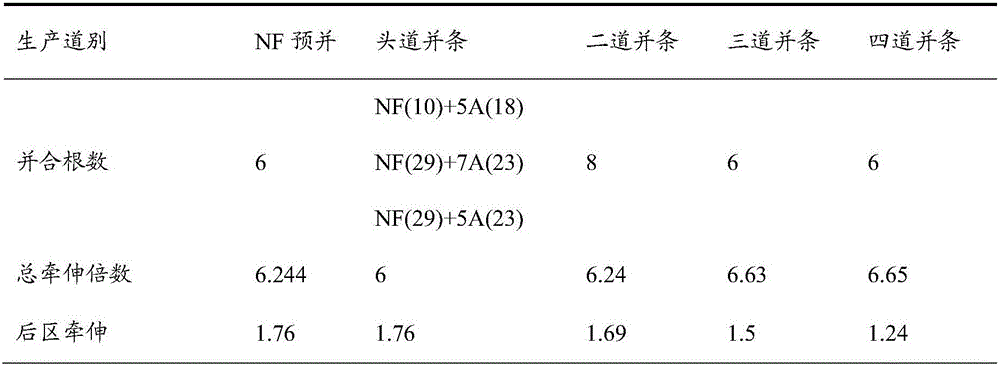

[0027] The preparation process of the aramid fiber and the nickel-iron fiber blended yarn of the present invention is mixed by a drawing process, wherein, the aramid fiber of the present invention adopts aramid fiber 1414,...

Embodiment 2

[0030] The specific steps of the preparation process of the aramid fiber and nickel-iron fiber blended yarn of the present invention are as follows:

[0031] Step A: cleaning and carding process, the aramid fiber of the present invention adopts aramid fiber 1414;

[0032] Step A1: Loosen the compressed aramid fiber 1414 into smaller fiber blocks or fiber bundles, so as to facilitate the smooth progress of mixing and impurity removal;

[0033] Step A2: Remove most of the impurities, defects and short fibers that are not suitable for spinning in the original pressed aramid 1414 fibers;

[0034] Step A3: Mixing the original aramid 1414 staple fibers of different compositions sufficiently and uniformly to stabilize the quality of the aramid 1414 fibers;

[0035] Step A4: A aramid 1414 fiber roll with a certain weight, length, uniform thickness and good shape is made.

[0036] Through the cleaning and carding process of this step, the aramid 1414 fibers are decomposed into a sing...

Embodiment 3

[0060] Performance testing of 3 blended yarns

[0061] The three kinds of aramid and nickel-iron blended yarns with different nickel-iron fiber contents of the present invention were respectively carried out in multiple groups of experiments to measure the yarn strength, yarn hairiness and abrasion resistance and conduct performance analysis. The specific results are shown in Table 6.

[0062] Table 6 Performance test results of nickel-iron fiber blended yarn

[0063]

[0064] Table 7 Comparison of nickel-iron fiber blended yarn of the present invention with other blended yarns

[0065]

[0066] The aramid fiber and nickel-iron fiber blended yarn of the present invention has good mechanical properties, high breaking strength and low elongation at break, and the aramid and nickel-iron fiber blended yarn of the present invention can be used for producing high strength and high strength Molded flame retardant textiles, and then through blending or finishing, endow them wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com