Preparation method of graded porous carbon material

A technology of hierarchical porous and carbon materials, applied in lithium-air batteries, containing microporous areas, can solve single problems, and achieve the effect of improving power performance and enhancing mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 1.6g of F127 and dissolve it in 8g of ethanol. After the solution is completely clarified, add 1.0g of 0.2M hydrochloric acid, add 2.08g of tetraethyl orthosilicate, 5g of silica microspheres with a particle size of 250nm and 5.0g of mass fraction 20% phenolic resin, stirred at room temperature for 5 hours to form a clear and transparent sol. The sol was placed in a watch glass, and the ethanol was allowed to evaporate naturally to obtain a gel. The gel was dried at 100°C in an air atmosphere for 24 h and then carbonized. The carbonization heating rate is 1°C / min, the temperature is raised to 900°C and kept for 5 hours. The carbonized product is soaked in a hydrofluoric acid solution with a mass fraction of 10% for 24 hours, and then filtered, washed and dried to obtain the final product.

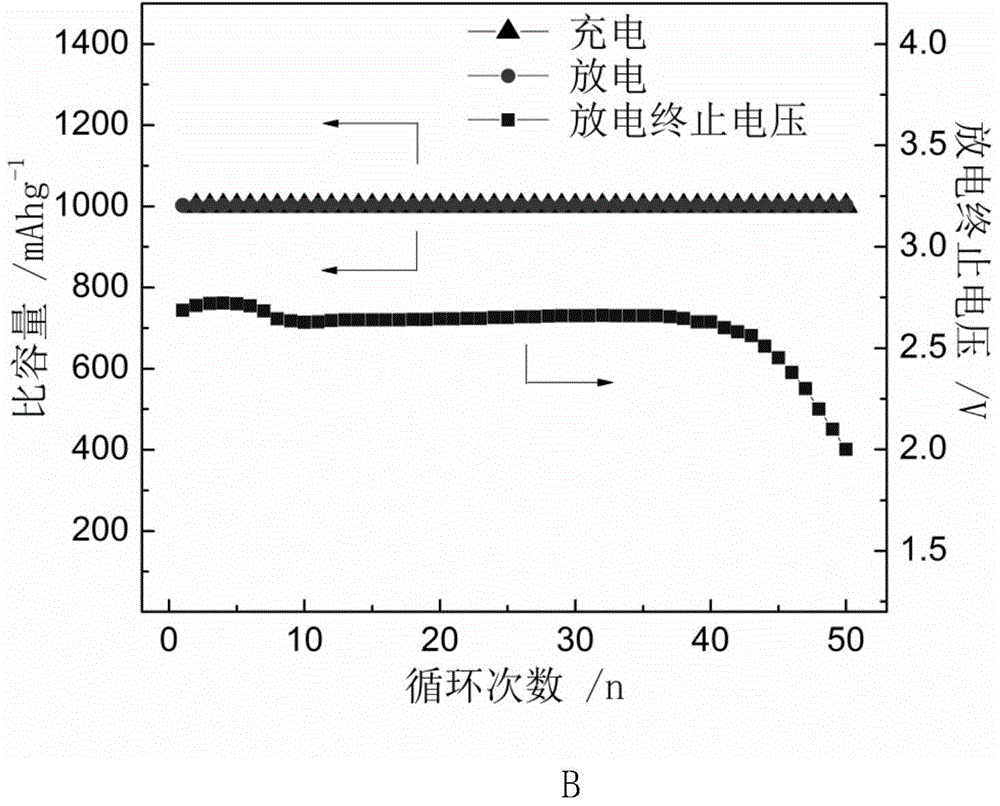

[0022] Take 500mg of this porous carbon material and mix it with 2.5g mass fraction of 5% polytetrafluoroethylene emulsion and 10ml isopropanol to prepare a slurry, then scra...

Embodiment 2

[0024] Weigh 2.4g of P123 and dissolve it in 8g of water. After the solution is completely clarified, add 1.0g of 0.2M hydrochloric acid, add 2.08g of tetraethyl orthosilicate, 6g of polymethyl methacrylate microspheres with a particle size of 200nm and 5.0g of The phenolic resin with a mass fraction of 20% was stirred at room temperature for 5 hours to form a clear and transparent sol. The sol was placed in a watch glass, and the ethanol was allowed to evaporate naturally to obtain a gel. The gel was dried at 100°C in an air atmosphere for 24 h and then carbonized. The carbonization heating rate is 1°C / min, the temperature is raised to 900°C and kept for 5 hours. The carbonized product is soaked in a hydrofluoric acid solution with a mass fraction of 10% for 24 hours, and then filtered, washed and dried to obtain the final product.

[0025] Take 500mg of this porous carbon material and mix it with 2.5g mass fraction of 5% polytetrafluoroethylene emulsion and 10ml isopropano...

Embodiment 3

[0027] Weigh 2.4g P123 and dissolve it in 8g of water. After the solution is completely clarified, add 1.0g of 0.2M hydrochloric acid, add 2.08g of orthosilicate, 4g of calcium carbonate microspheres with a particle size of 100nm, and 10g of calcium carbonate microspheres with a mass fraction of 40%. The sucrose solution was stirred at room temperature for 5 hours to form a clear and transparent sol. The sol was placed in a watch glass, and the watch glass was placed on a hot stage at 40° C. to evaporate the water to obtain a gel. The gel was dried at 100°C in an air atmosphere for 24 h and then carbonized. The carbonization heating rate is 1°C / min, the temperature is raised to 900°C and kept for 5 hours. The carbonized product is soaked and washed in deionized water to remove the calcium oxide component. Then put the carbonized product into a hydrofluoric acid solution with a mass fraction of 10% to soak for 24 hours, and then filter, wash and dry to obtain the final produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com