Manufacturing method of ultra-thin printed circuit board and ultra-thin printed circuit board

A technology of printed circuit board and manufacturing method, which is applied in the field of circuit board manufacturing to achieve the effects of avoiding scrapping, avoiding deformation, and preventing the phenomenon of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The manufacture method of ultra-thin printed circuit board is characterized in that, comprises the steps:

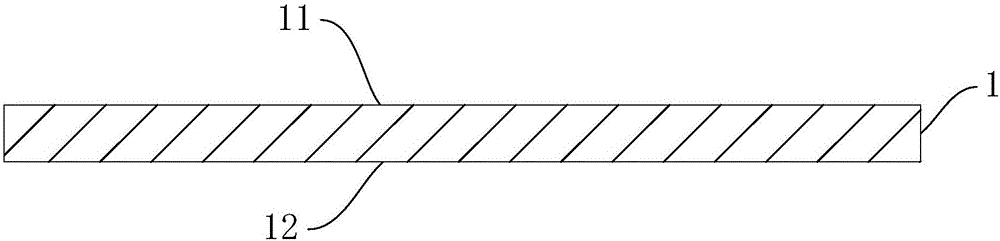

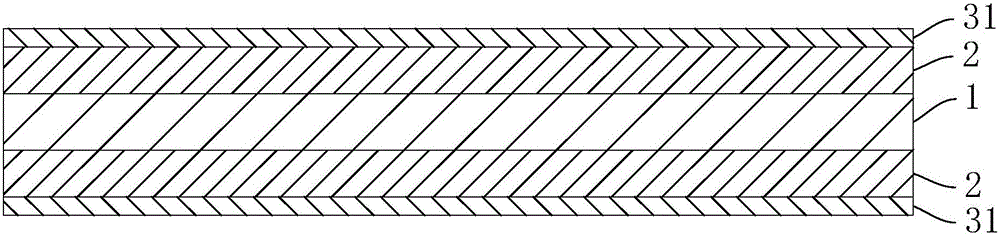

[0073] a. If figure 1 As shown, a carrier 1 is provided, and the carrier 1 is made of a polymer material. The carrier board 1 has a first surface 11 and a second surface 12 oppositely disposed. Such as figure 2 As shown, the metal layer 2 is respectively disposed on the first surface 11 and the second surface 12 of the carrier 1 . The metal layer is a copper layer, an aluminum layer or an alloy metal layer. The first copper foil 31 is provided on the metal layer 2 . The first copper foil 31 is bonded to the metal layer 2 .

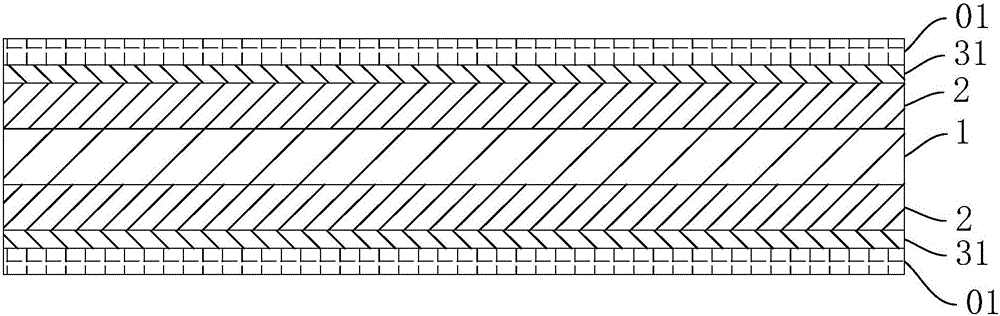

[0074] b. Perform electroplating treatment on the carrier plate 1 provided with the metal layer 2 and the first copper foil 31 . The specific process of electroplating treatment is as follows: image 3 As shown, an insulating film is provided on the surface of the first copper foil 31 . In this embodiment, photosensitive film 01 is us...

Embodiment 2

[0081] Such as Figure 17 As shown, on the basis of Example 1, before the first copper foil 31, the first conductive circuit layer 41, the first bonding sheet 51 and the second conductive circuit layer 42 bonded to each other are peeled off from the metal layer 2, the A layer of second bonding sheet 52 and a layer of third copper foil 33 are sequentially stacked on the surface of the second conductive circuit layer 42 . The third copper foil 33 is bonded to the second conductive circuit layer 42 through the second bonding sheet 52 . Such as Figure 18 As shown, laser drilling is performed on the third copper foil 33 to form the second hole 62 . The second hole 62 extends from the third copper foil to the second conductive circuit layer 42 . Such as Figure 19 As shown, the second hole 62 is produced by electroless copper plating and copper plating, so that the second hole 62 is filled with copper 621, and the second hole 62 filled with copper 621 connects the third copper ...

Embodiment 3

[0085] Such as Figure 24 As shown, different from Embodiment 2, the second hole 62 formed by laser drilling on the third copper foil 33 in this embodiment extends from the third copper foil 33 to the first conductive circuit layer 41 . Such as Figure 25 As shown, electroless copper plating and copper electroplating are performed on the second hole 62, so that the second hole 62 is filled with copper 621, and the second hole 62 filled with copper 621 conducts electricity to the third copper foil 33 and the first conductive circuit layer 41 connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com