High-power brushless doubly-fed motor three-level two-way frequency conversion speed regulation system

A technology of doubly-fed motor and variable frequency speed regulation, applied in control systems, control generators, vector control systems, etc., can solve the problems of complex structure, control system structure and control algorithm difficulty, etc., to achieve energy feedback, harmonic content and other problems. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention is described in detail below in conjunction with the accompanying drawings

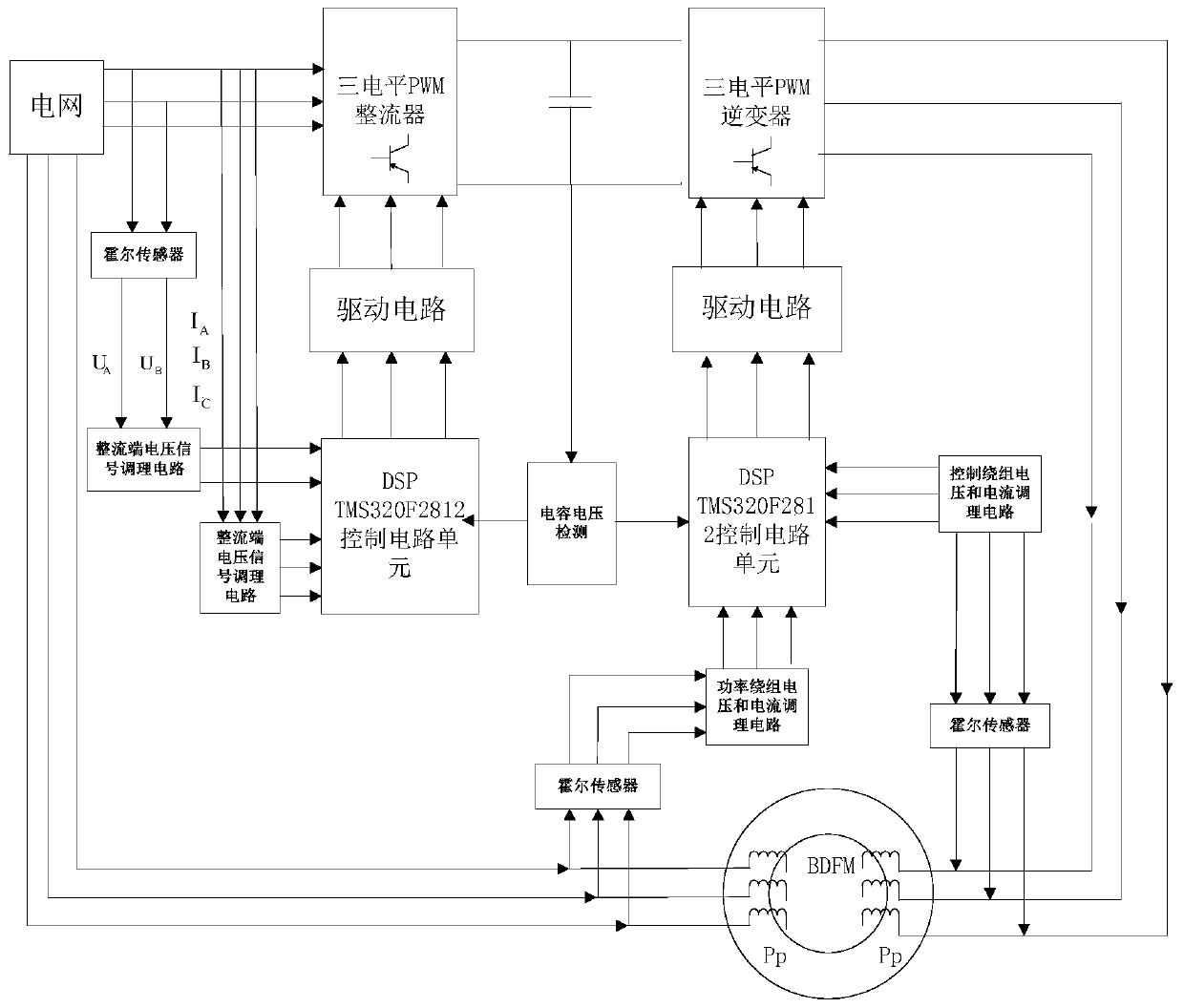

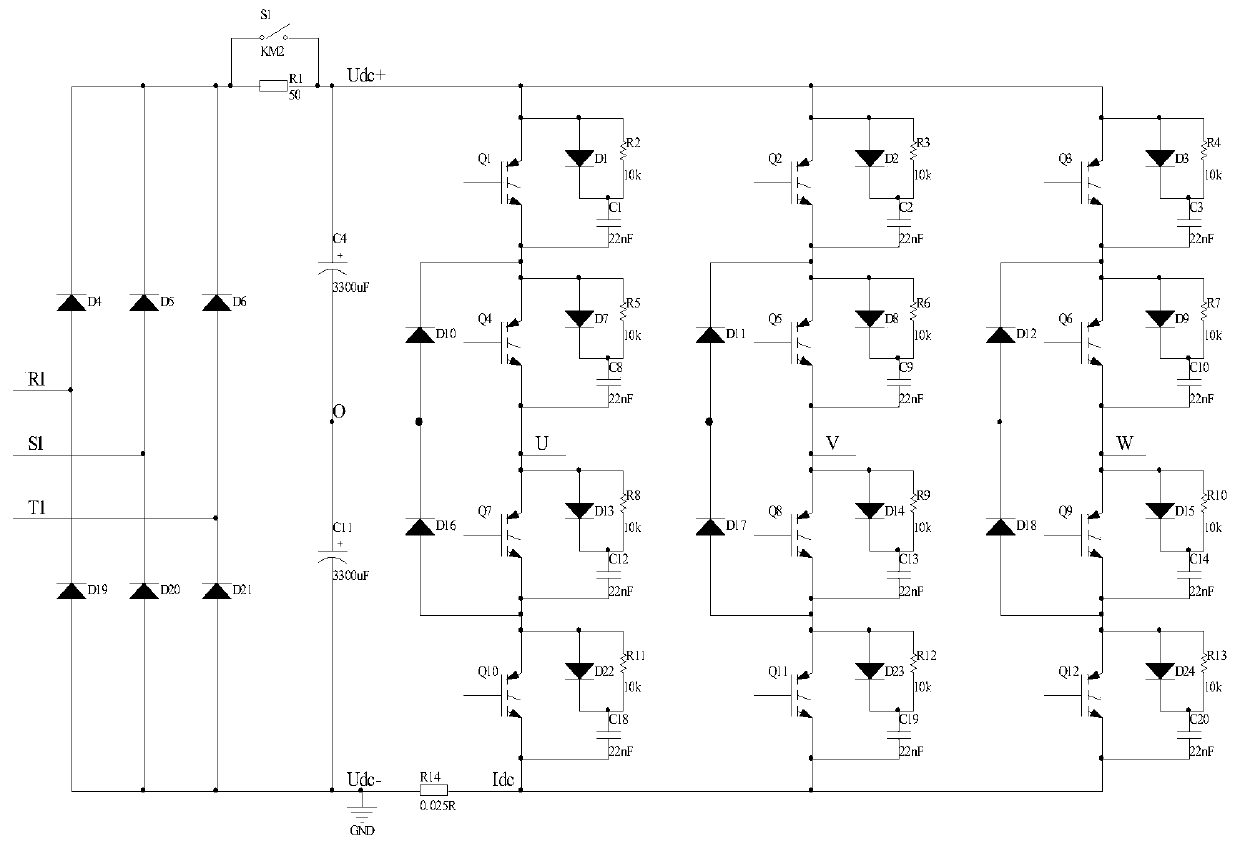

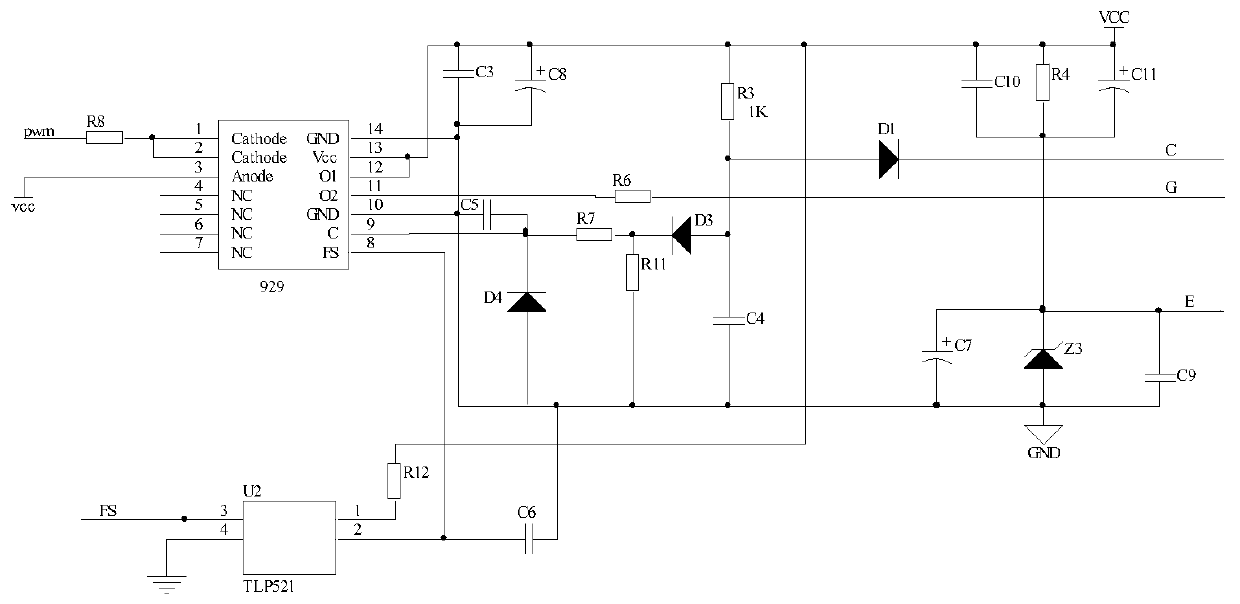

[0037] figure 1 The structural block diagram of the high-power brushless double-fed motor three-level bidirectional frequency conversion speed regulation system designed for the present invention, the system includes a brushless double-fed motor; the brushless double-fed motor three-level PWM rectifier unit: including a control circuit board Unit, Hall sensor, rectifier terminal AC voltage, current signal conditioning circuit unit, rectifier drive circuit unit; brushless double-fed motor three-level inverter unit: including inverter main circuit unit, Hall sensor voltage and current detection unit , Power winding AC voltage, current signal conditioning circuit unit, control winding AC voltage, current signal conditioning circuit unit, DC terminal voltage detection circuit unit, inverter drive circuit unit;

[0038] Such as figure 1 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com