Preparation method for nitride light emitting diode chip

A technology of light-emitting diodes and nitrides, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor repeatability, complex process, and high control accuracy, and achieve the effects of low cost, improved doping efficiency, and improved luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

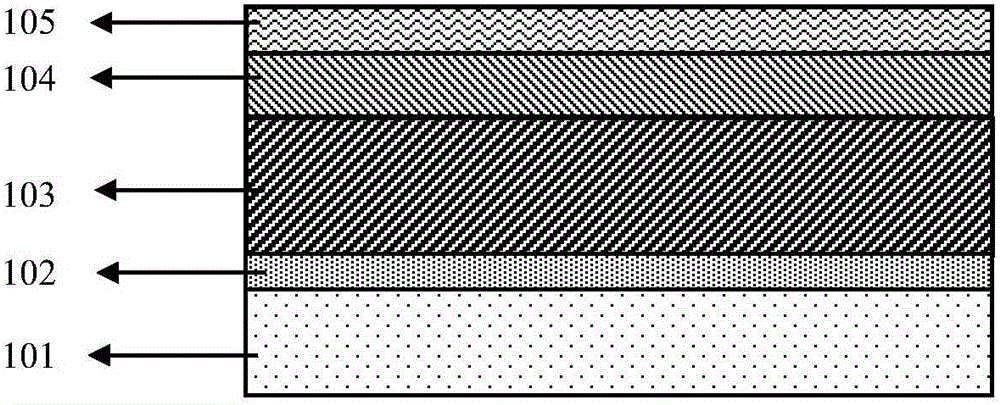

[0065] A method for preparing a nitride light-emitting diode chip according to this embodiment, the steps are as follows:

[0066] In the first step, the sapphire substrate 101 is baked at 1200°C in a MOCVD (metal organic compound chemical vapor deposition) reaction furnace to remove foreign matter on the substrate surface;

[0067] In the second step, in the MOCVD reaction furnace, a buffer layer 102 made of AlN with a thickness of 10 nm is epitaxially grown on the surface of the sapphire substrate 101 after the first step;

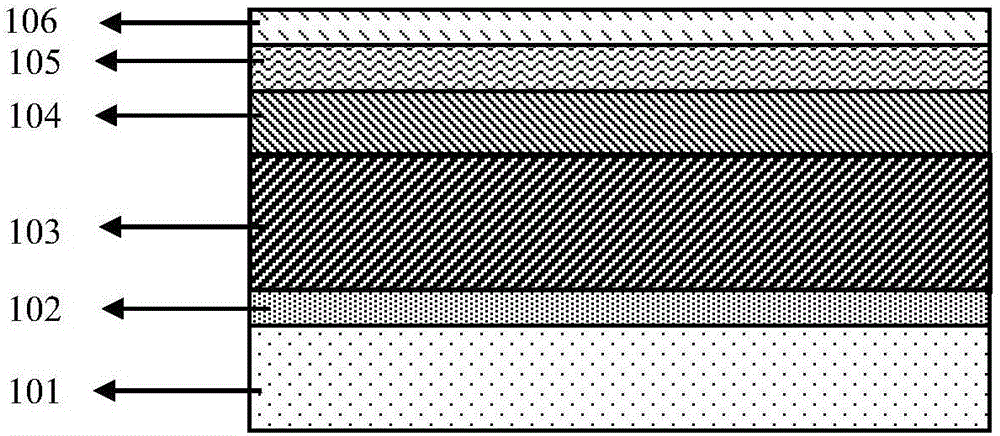

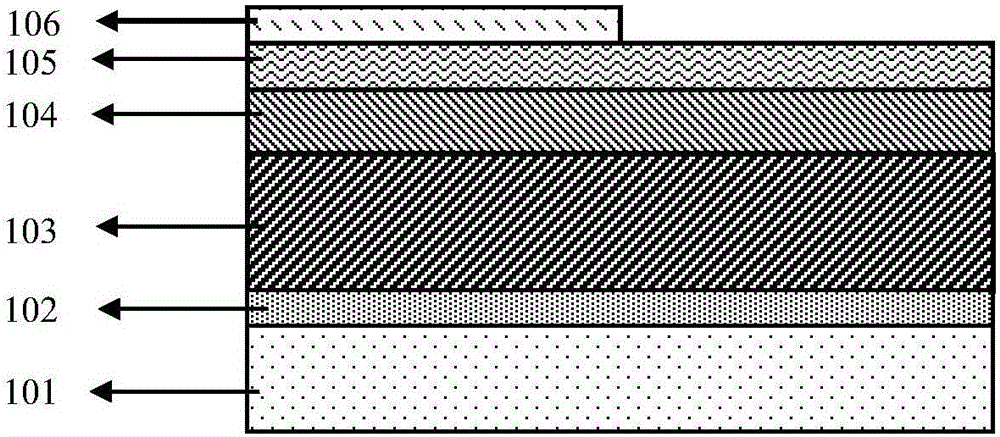

[0068] In the third step, in the MOCVD reaction furnace, on the buffer layer 102 obtained in the second step, an N-type semiconductor material 103 made of AlN with a thickness of 2 μm is epitaxially grown sequentially, and the material is Al 0.9 Ga 0.1 The thickness of the quantum barrier AlN of N / AlN is 5nm and the quantum well Al 0.9 Ga 0.1 N multi-quantum well layer 104 with a thickness of 1 nm and a P-type semiconductor material 105 made of AlN wi...

Embodiment 2

[0076] Except that the substrate 101 is AlN, the material of the current spreading layer 106 is graphene, the insulating layer 107 is LiF, and the position and step pattern of the part of the insulating layer 107 remaining on the step pattern II of the N-type semiconductor material 103 in the sixth step The distance between the sidewalls of II is 50 microns, and the distance between the portion of the insulating layer 107 remaining on the step pattern I on the P-type semiconductor material 105 and the sidewall of the step pattern I is 50 microns, and the others are the same as in Embodiment 1.

Embodiment 3

[0078] Except that the substrate 101 is quartz glass, the material of the current spreading layer 106 is aluminum, the insulating layer 107 is PMMA, and the position and the step pattern of the insulating layer 107 remaining on the step pattern II of the N-type semiconductor material 103 in the sixth step The distance between the sidewalls of II is 100 microns, and the distance between the portion of the insulating layer 107 remaining on the step pattern I on the P-type semiconductor material 105 and the sidewall of the step pattern I is 100 microns, and the others are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com