A novel wafer thinning method

A new type of wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as affecting the test yield and difficult to clean small particles, to improve the quality of thinning and test yield, avoid The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

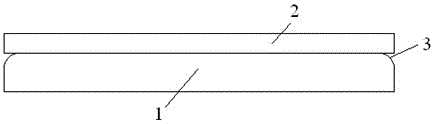

Image

Examples

Embodiment 1

[0032] Take the polyimide solution, then take polytetrafluoroethylene according to 20% of the quality of the polyimide solution taken, add the polytetrafluoroethylene into the polyimide solution, put it on a rolling machine, roll, and stir evenly , to form a coating liquid; use a coating machine to coat the coating liquid on the front of the original wafer, so that the coating liquid evenly and tightly covers the front of the original wafer and the chamfering of the edge, and bake at a temperature of 60 ° C After 20 minutes, the coating solution is hardened to form a covering layer, which realizes seamless protection for the chips on the original wafer. Set the process parameters according to the existing coarse grinding process requirements on the thinning machine, and carry out rough grinding to the original wafer to achieve the rough grinding thickness of the original wafer required by the rough grinding process; press the existing rough grinding process on the thinning mach...

Embodiment 2

[0034]Take the PTFE UV adhesive film, cover the front surface of the original wafer and the edge chamfer with the PTFE UV adhesive film, bake at 50°C for 10 minutes, and the PTFE UV adhesive film will soften , to remove the air bubbles between the PTFE UV film and the original wafer, and the PTFE UV film is tightly pasted on the front of the wafer and the chamfering of the edge to form a covering layer, which is opposite to the original The chip on the wafer realizes seamless protection; on the thinning machine, the process parameters are set according to the existing rough grinding process requirements, and the original wafer is roughly ground to meet the coarse grinding process requirements. Thickness; on the thinning machine, the process parameters are set according to the existing fine grinding process requirements, and the original wafer after rough grinding is finely ground to achieve the thickness and roughness of the wafer after fine grinding required by the fine grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com