Method for dredging bottom slag in 55% Al-Zn liquid

A zinc liquid, aluminum-zinc technology, applied in the coating, metal material coating process, hot-dip galvanizing process, etc., can solve the problems of sedimentation at the bottom of the zinc pot, failure to produce, damage to the zinc pot body, etc., to improve slag removal The efficiency and slag removal effect, the effect of improving the slag removal efficiency and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

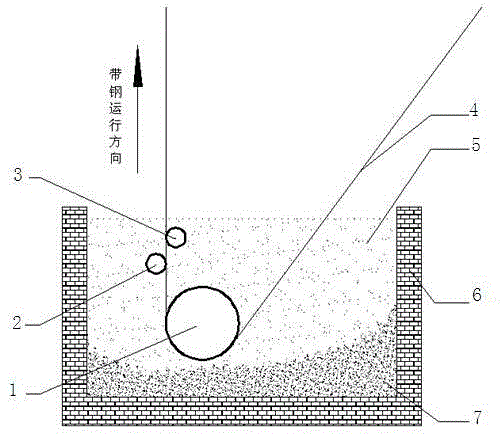

[0023] See figure 1 — Figure 4 , 55% aluminum-zinc liquid bottom slag fishing method, the method includes the following steps,

[0024] 1) See figure 1 , Lift out the sinking roller 1, the correction roller 2, the stabilization roller 3, and remove the strip steel 4 to ensure that there is no other equipment in the zinc pot 6 except for the aluminum-zinc liquid, which facilitates slag removal and prevents damage to the equipment during the temperature change of the zinc liquid , And the stability of the composition of aluminum and zinc liquid;

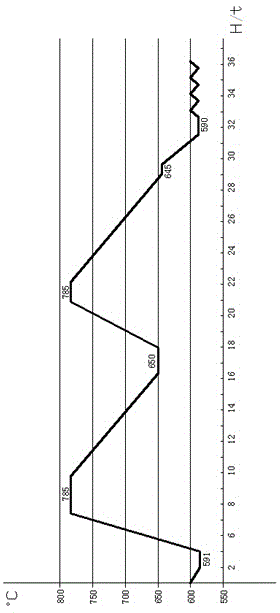

[0025] 2) Reduce the temperature of the aluminum-zinc solution in the zinc pot from the standard temperature of 600±3°C to 591°C at a rate of 5°C / H, and keep it for 2 hours to reduce the dissolved Fe content in the aluminum-zinc solution, and let it become a slag Fe-Al compound and bottom dross, namely Fe-Zn compound, are precipitated. After precipitation, slag removal is carried out. Fe is the main component of zinc slag. In practice, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com